Display panel, display device and preparation process of display panel

A display panel and backplane technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as OLED device failure and impact on OLED devices, increase graphic design, reduce process difficulty, and improve packaging effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

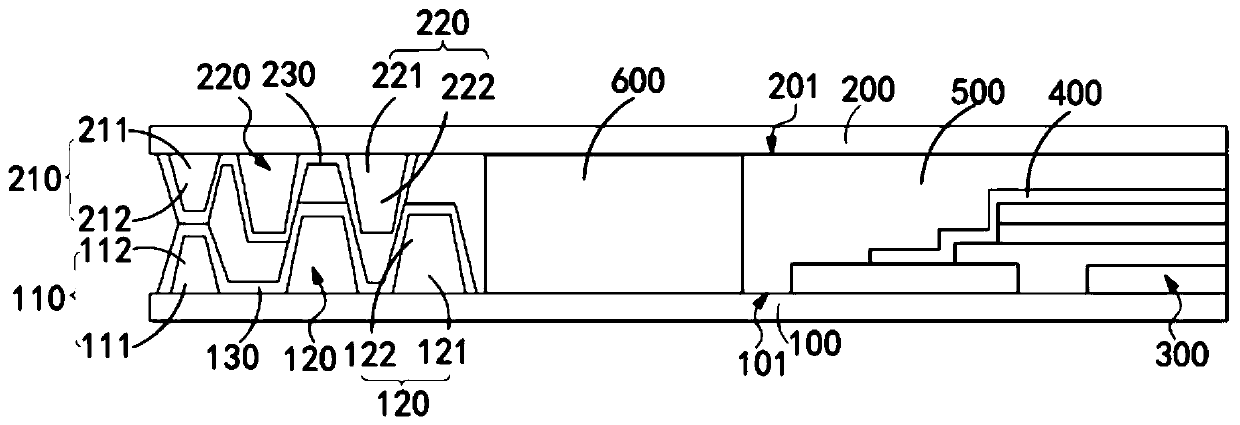

[0106] refer to Figure 5 , which representatively shows a partial cross-sectional view of another embodiment of the display panel proposed in the present disclosure. In this exemplary embodiment, the design of the display panel proposed by the present disclosure is substantially the same as that of the display panel in the first embodiment. The design of the display panel in this embodiment that is different from the above embodiments will be described below.

[0107] Such as Figure 5 As shown, in this embodiment, the display panel proposed in the present disclosure only includes the first spacer 110 and the second spacer 210 , but does not include the third spacer 120 and the fourth spacer 220 . Specifically, the first spacer 110 and the second spacer 210 abut against each other to provide the function of blocking water and oxygen. Through the above design, the display panel proposed in the present disclosure can further meet the design requirements of devices with narro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com