Automatic treatment device for architectural engineering construction waste

An automatic processing and construction engineering technology, which is applied in grain processing, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of not being able to sort multiple wastes at the same time, and slow processing efficiency, so as to avoid derailment and improve the effect , the effect of reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

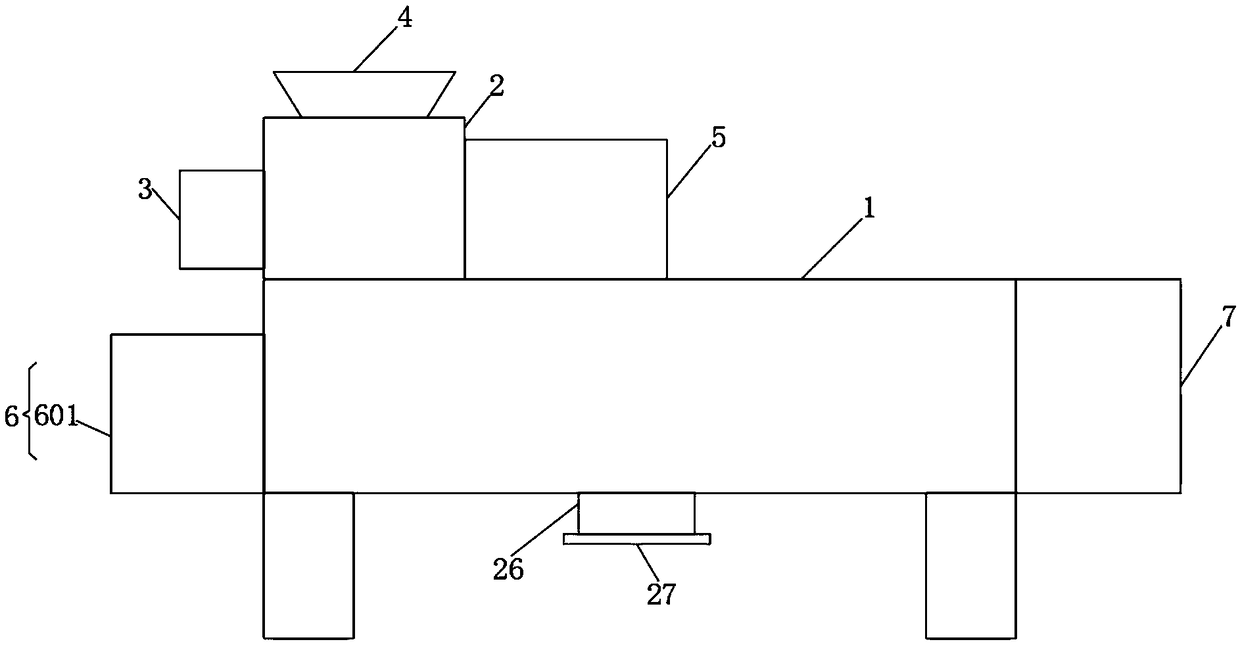

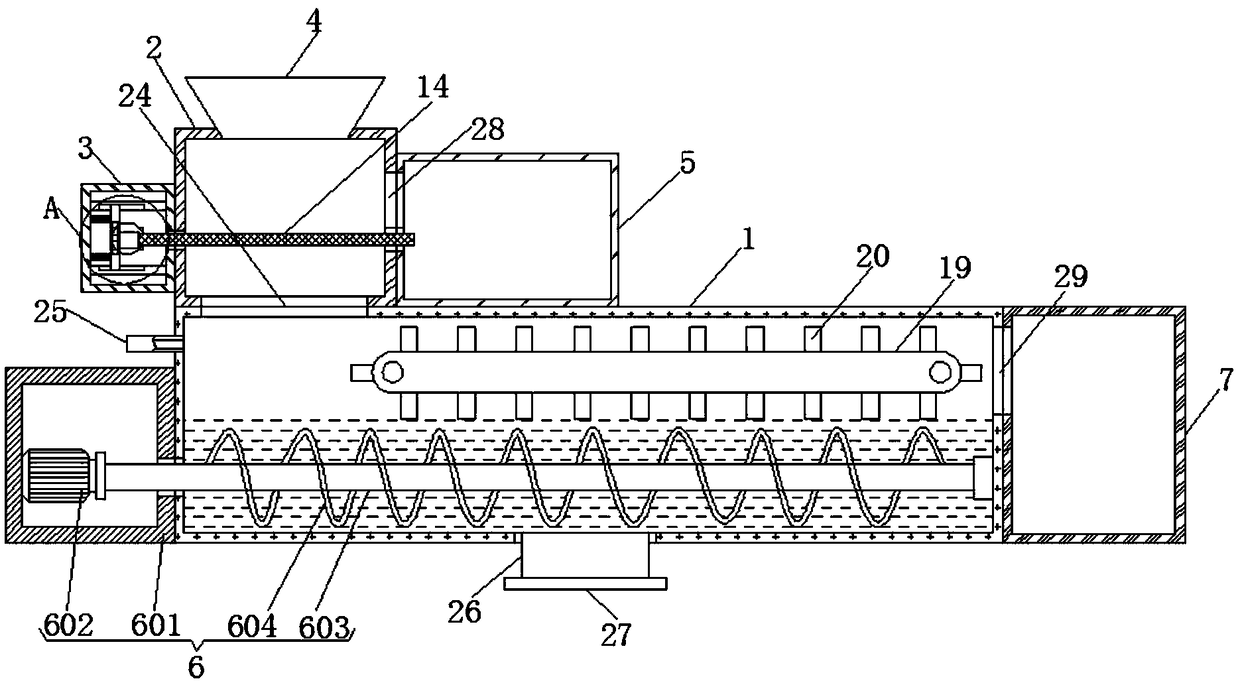

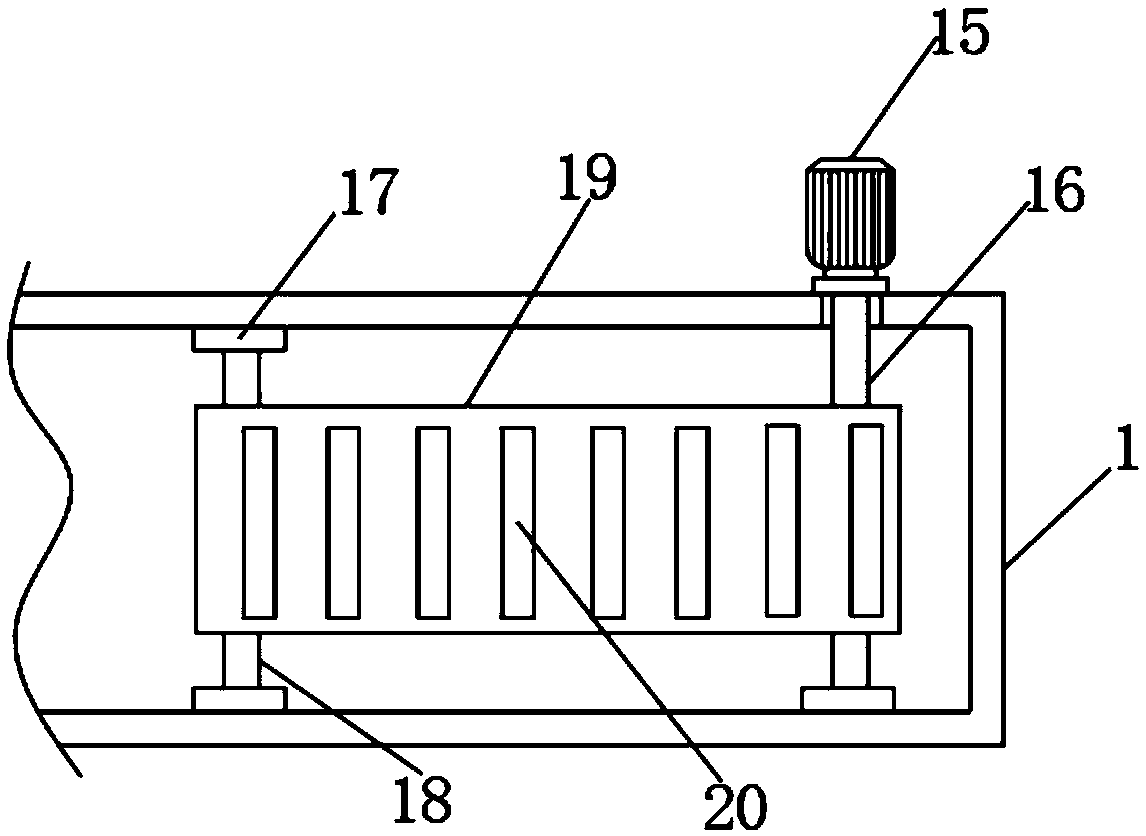

[0027] Embodiment 1: The automatic processing device for building engineering construction waste of the present invention includes a sorting box 1, and is characterized in that: the left side of the top of the sorting box 1 is fixedly connected with a screening box 2, and the left side of the screening box 2 is fixedly connected with a transmission The top of the box 3 and the screening box 2 is connected with a feed hopper 4, the right side of the screening box 2 is fixedly connected with the first storage box 5, the left side of the sorting box 1 is fixedly connected with a stirring and mixing mechanism 6, and the left side of the sorting box 1 The right side is fixedly connected with a second storage box 7, the top and bottom of the inner chamber of the transmission box 3 are fixedly connected with a slide plate 8 horizontally, the back side of the inner chamber of the transmission box 3 is fixedly connected with a first motor 9, and the output of the first motor 9 The end i...

Embodiment 2

[0028]Embodiment 2: The automatic processing device for building engineering construction waste of the present invention includes a sorting box 1, which is characterized in that: the left side of the top of the sorting box 1 is fixedly connected with a screening box 2, and the left side of the screening box 2 is fixedly connected with a transmission The top of the box 3 and the screening box 2 is connected with a feed hopper 4, the right side of the screening box 2 is fixedly connected with the first storage box 5, the left side of the sorting box 1 is fixedly connected with a stirring and mixing mechanism 6, and the left side of the sorting box 1 The right side is fixedly connected with a second storage box 7, the top and bottom of the inner chamber of the transmission box 3 are fixedly connected with a slide plate 8 horizontally, the back side of the inner chamber of the transmission box 3 is fixedly connected with a first motor 9, and the output of the first motor 9 The end ...

Embodiment 3

[0029] Embodiment 3: The automatic processing device for building engineering construction waste of the present invention includes a sorting box 1, and is characterized in that: the left side of the top of the sorting box 1 is fixedly connected with a screening box 2, and the left side of the screening box 2 is fixedly connected with a transmission The top of the box 3 and the screening box 2 is connected with a feed hopper 4, the right side of the screening box 2 is fixedly connected with the first storage box 5, the left side of the sorting box 1 is fixedly connected with a stirring and mixing mechanism 6, and the left side of the sorting box 1 The right side is fixedly connected with a second storage box 7, the top and bottom of the inner chamber of the transmission box 3 are fixedly connected with a slide plate 8 horizontally, the back side of the inner chamber of the transmission box 3 is fixedly connected with a first motor 9, and the output of the first motor 9 The end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com