Hybrid power module

A hybrid power module and actuator technology, which is applied in control devices, transportation and packaging, vehicle parts, etc., can solve the problem of poor connection stability between the actuator and the hybrid power module cavity wall, and achieve good connection stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

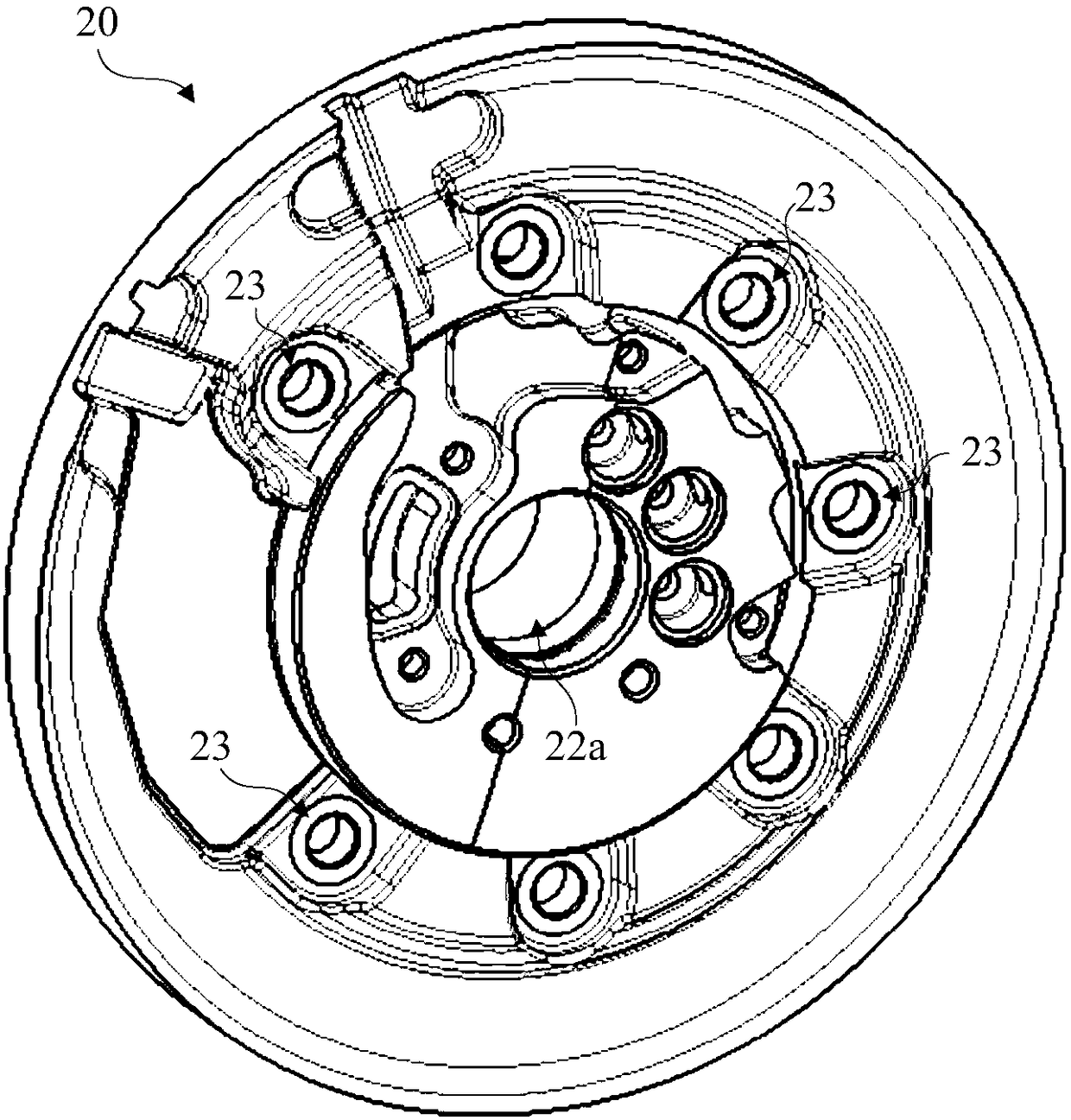

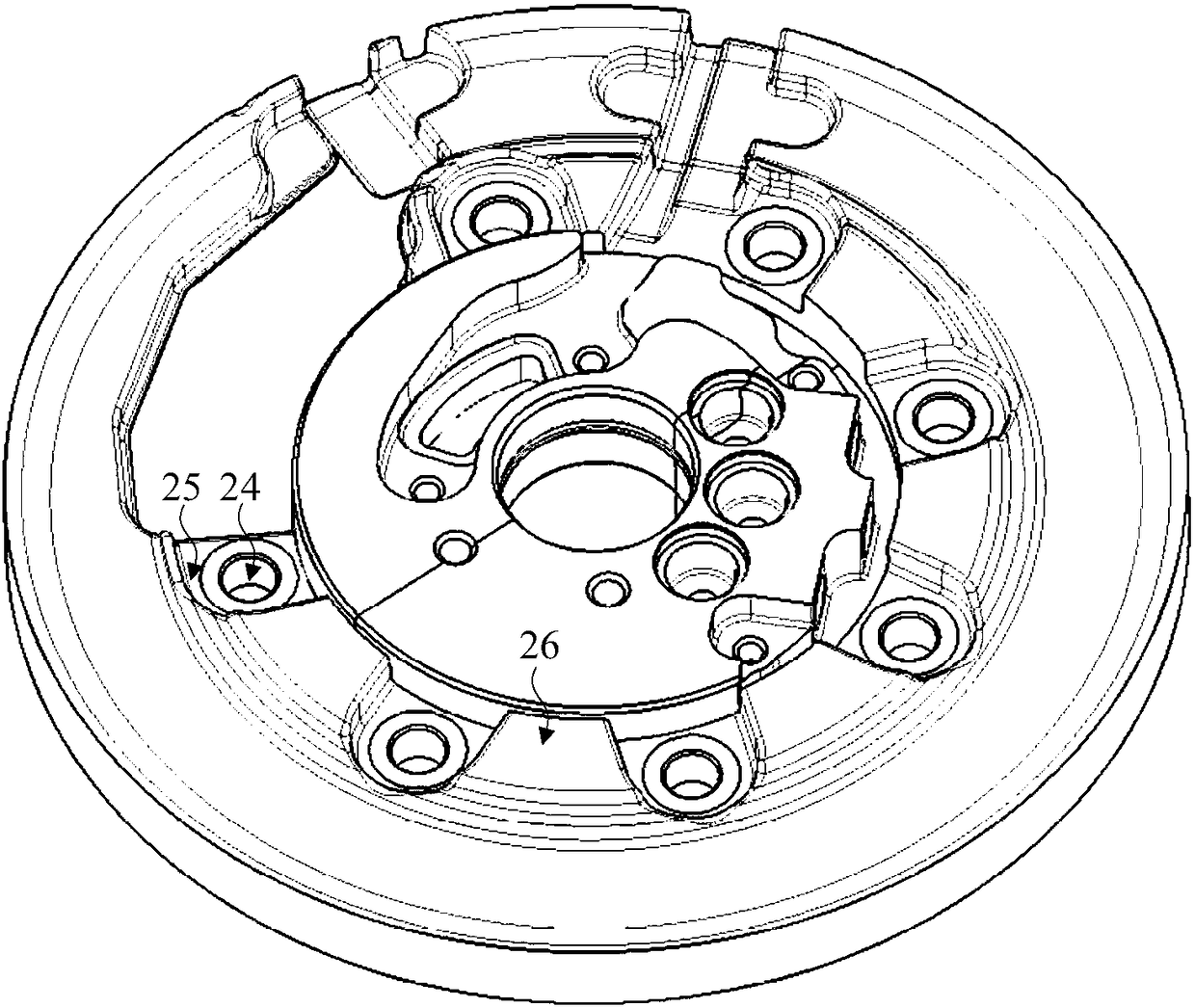

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

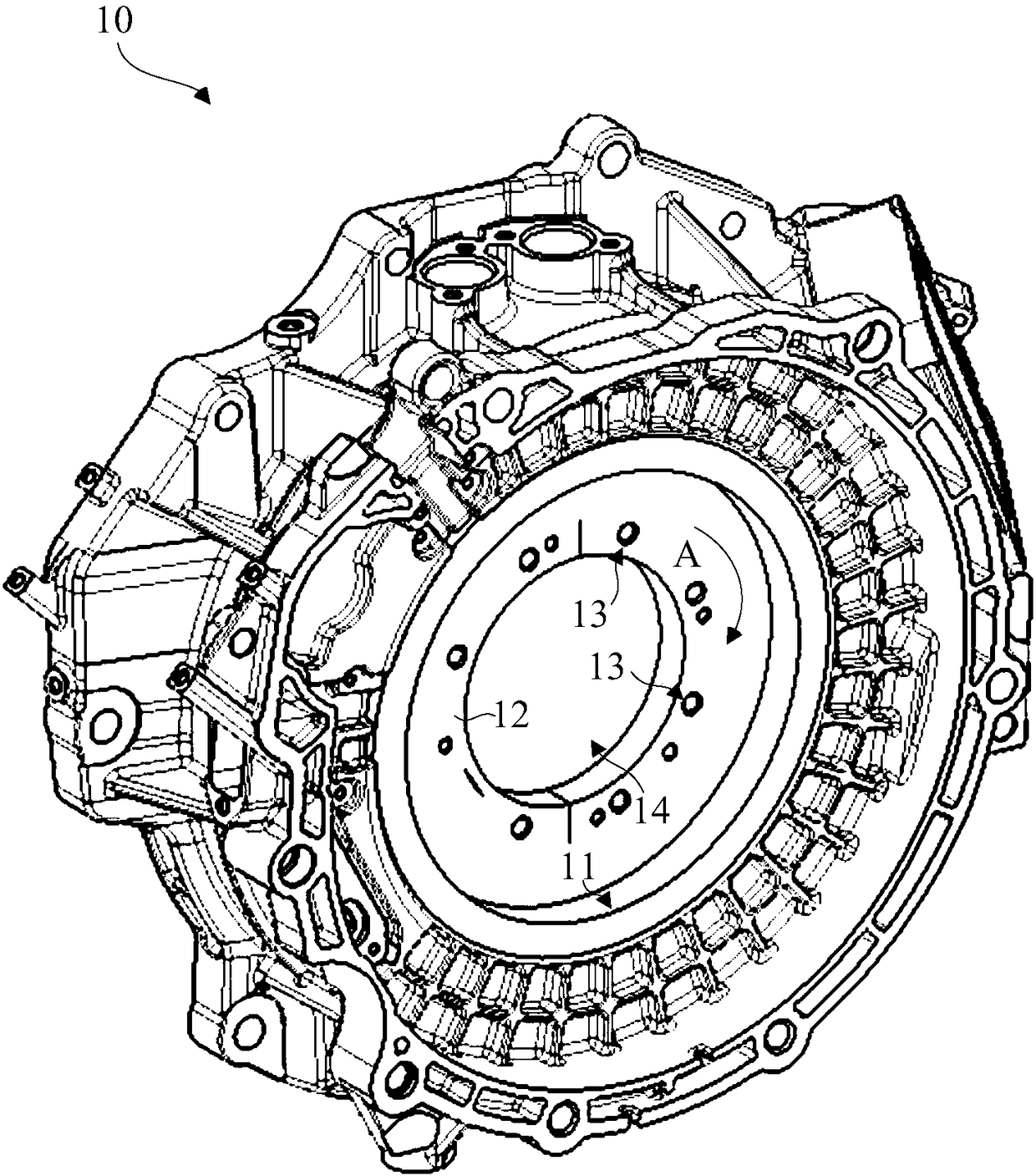

[0030] The present invention provides a hybrid power module, with reference to figure 1 , the hybrid module includes: a housing 10, the housing 10 has an inner cavity, and a clutch (not shown in the figure), a motor (not shown in the figure), an external rotor resolver (in the figure) are arranged in the inner cavity of the housing 10 not shown) and other components. The hybrid module is arranged between the engine (not shown in the figure) and the transmission (not shown in the figure), that is, the motor and the clutch are installed between the transmission box and the engine. Wherein, the clutch is retracted inside the motor, and this type of hybrid module is called a P2 hybrid module.

[0031] refer to figure 1 , along the circumfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com