Super high-rise contraction structure construction elevator corridor and manufacturing method thereof

A technology for constructing elevators and manufacturing methods, which is applied to elevators, transportation and packaging in buildings, etc., can solve problems such as personnel and materials cannot reach the floors, the distance between edges increases, and normal construction is affected, and achieves wide practicability and efficiency. The effect of promotion, easy installation and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

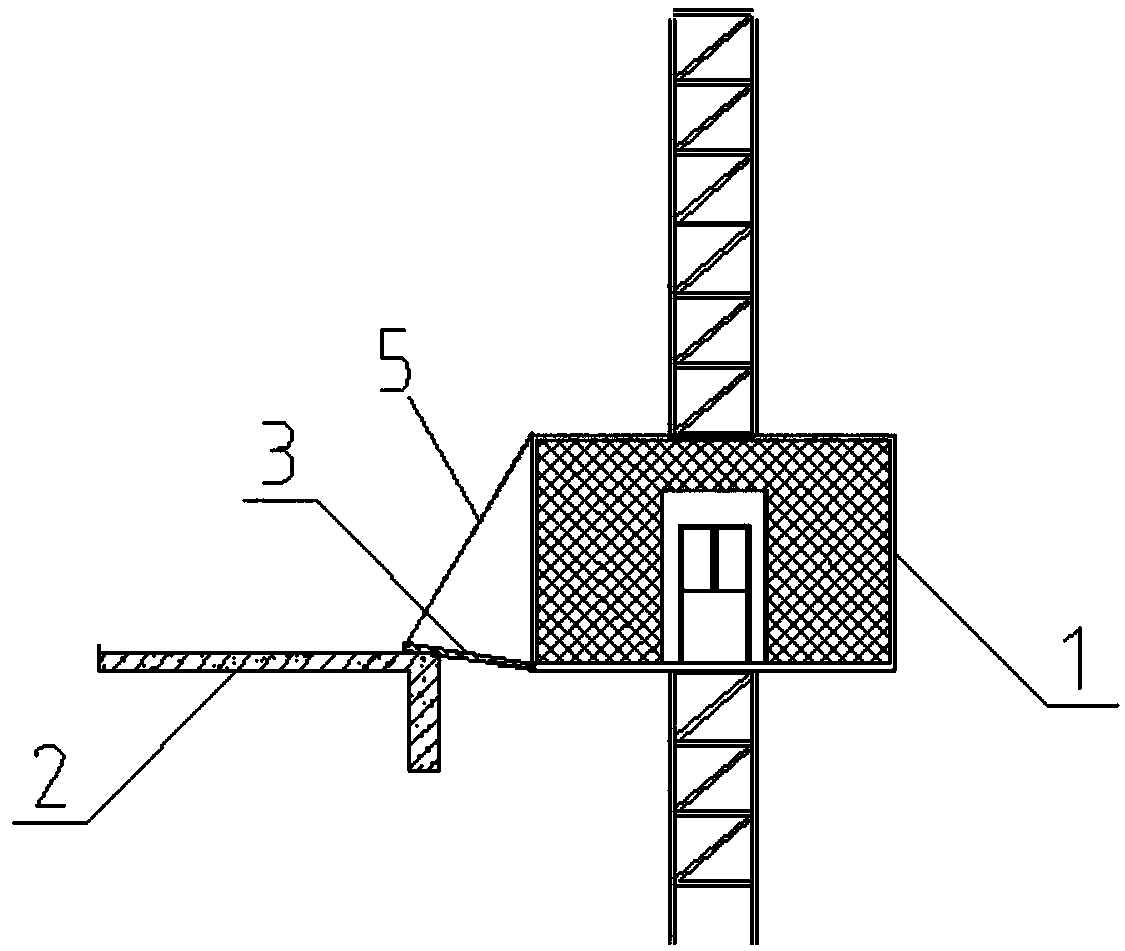

[0017] see figure 1 and figure 2 , a construction elevator corridor of a super high-rise shrinkage structure of the present invention, comprising a construction elevator 1 and a building structure 2, a flap door 3 is installed at the exit of the construction elevator 1, and the lower end of the flap door 3 is connected to the construction elevator 1 exit The bottom of the flap door 3 is rotated and connected, and the upper end of the flap door 3 is tied with the top of the construction elevator 1 exit by a steel wire rope 5. The flap door 3 is turned downwards and expanded and then connected with the building structure 2 to form a connected construction elevator corridor.

[0018] When making the construction elevator corridor of the above-mentioned super high-rise contraction structure, firstly, the existing elevator door of the construction elevator 1 is replaced with a flap door 3 that can be turned up and down, and the lower end of the flap door 3 is rotationally connecte...

Embodiment 2

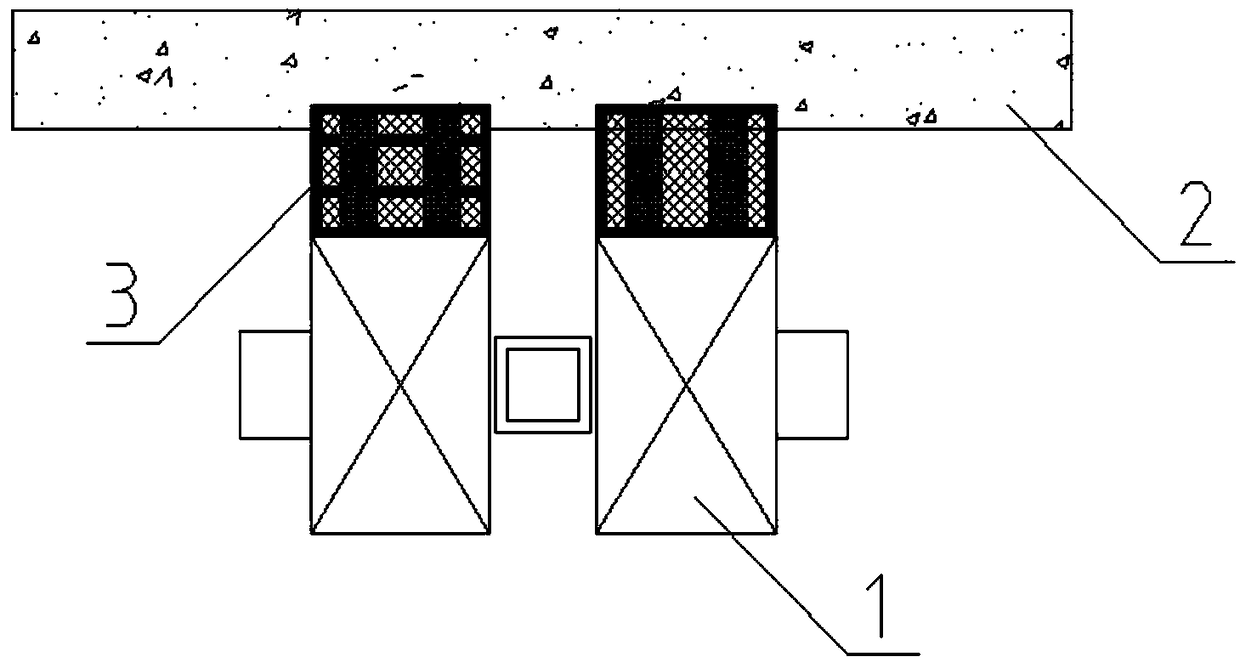

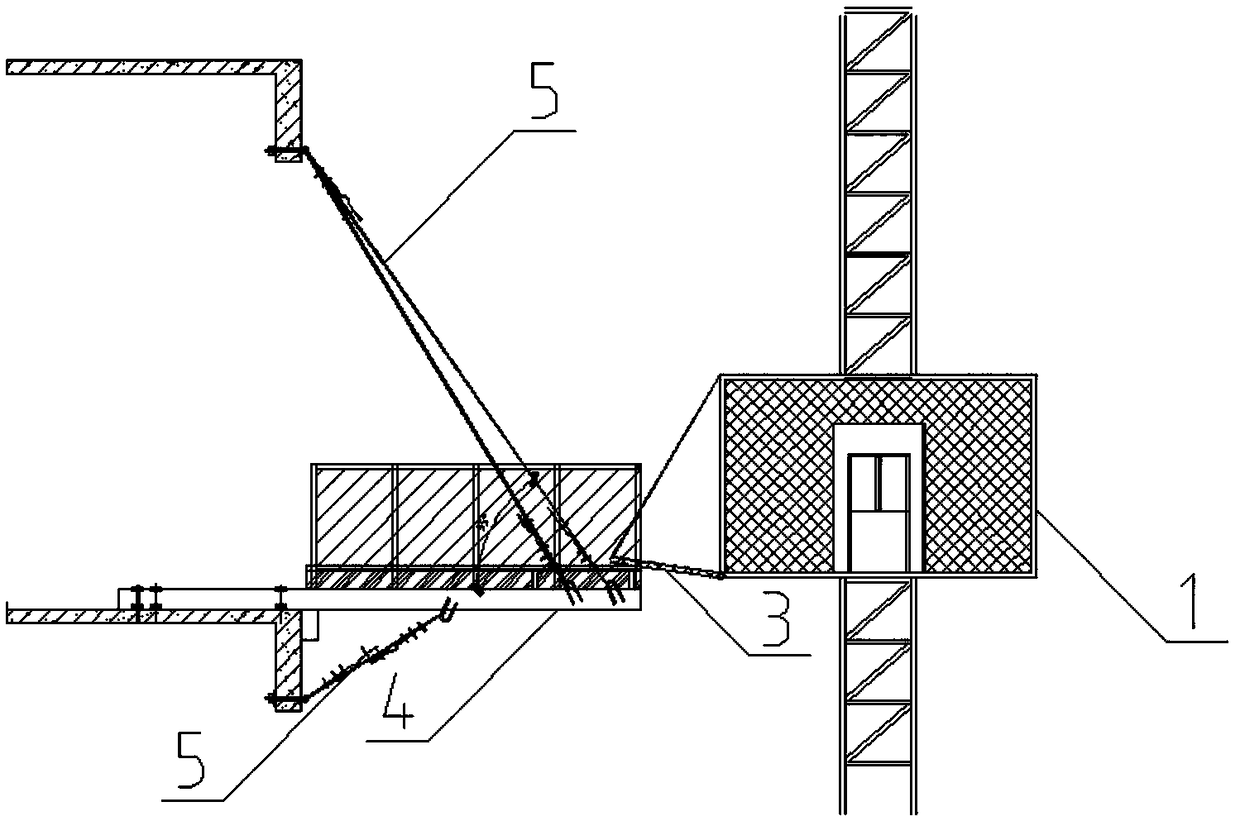

[0020] see image 3 and Figure 4 The above-mentioned construction elevator corridor also includes a cantilevered steel corridor 4 installed in the building structure 2 floors, the outer end of the cantilevered steel corridor 4 is fixed with the superstructure 2 by steel wire rope 5, The bottom is tied and fixed with the building structure 2 of this floor by a steel wire rope 5, and the flap door 3 is flipped downwards and unfolded, and then docked with the cantilevered steel corridor 4 to form a connected construction elevator corridor. The cantilevered steel corridor 4 includes two main keels 6 fixed in parallel on the floor of the building structure 2 and a group of secondary keels 7 vertically welded on the two main keels 6 , on which a checkered steel plate 8 is welded .

[0021] When making the construction elevator corridor of the above-mentioned super high-rise contraction structure, firstly, the existing elevator door of the construction elevator 1 is replaced with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com