A pipe column foundation structure for rapid turnover construction and its application method

A pipe column foundation and fast technology, which is applied in the direction of basic structure engineering, construction, bridge construction, etc., can solve the problems of inability to achieve rapid turnover and rapid construction, reduce the safety performance of the pipe column foundation structure, and affect the force effect of the steel pipe column, etc. , to achieve the effect of saving erection efficiency, saving labor time, and reducing the workload of on-site workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

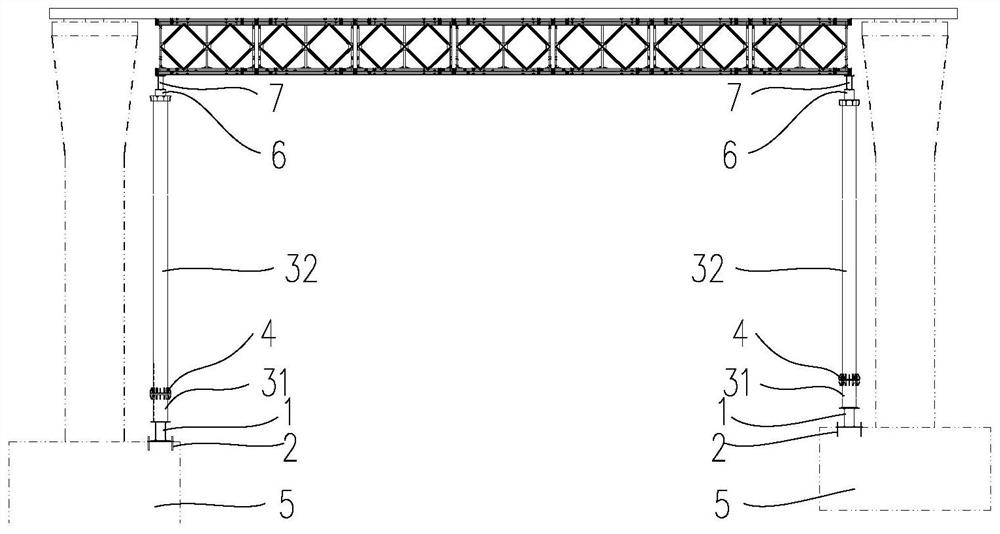

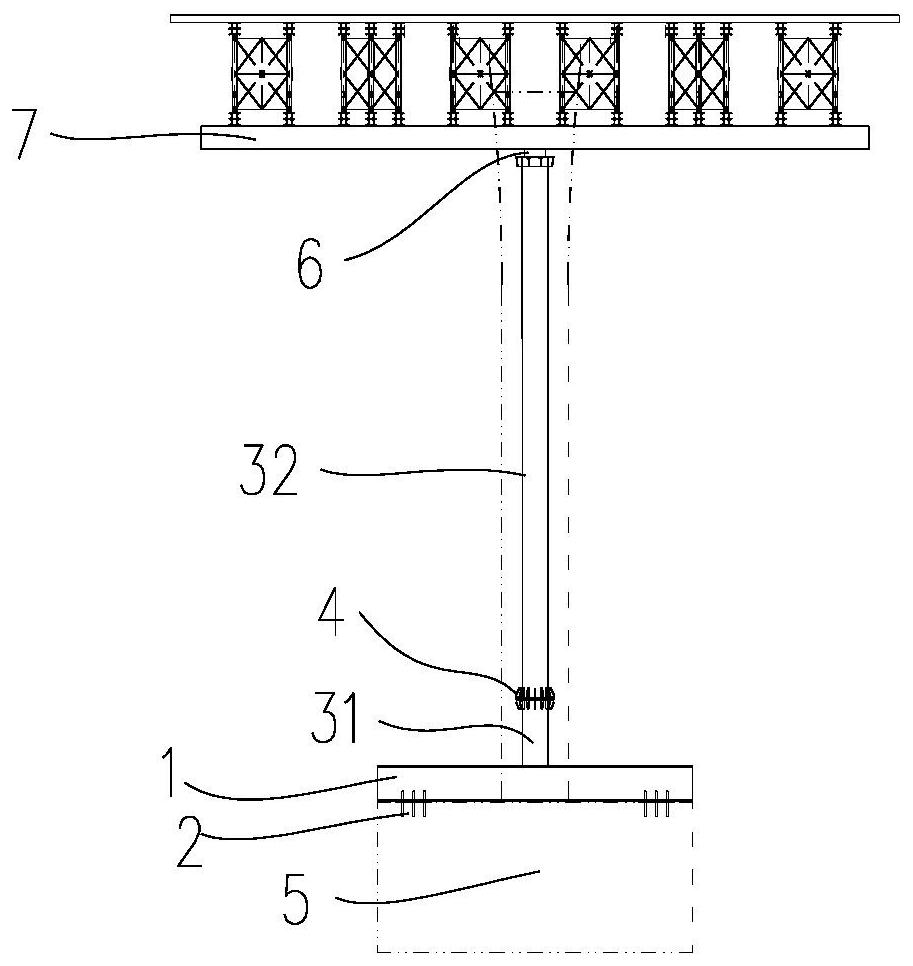

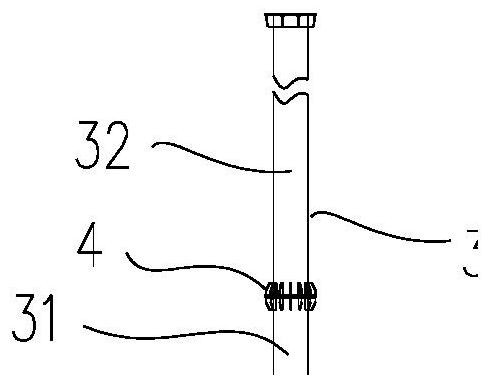

[0049] see Figure 1~3 As shown, the embodiment of the present invention provides a pipe column foundation structure for rapid turnover construction, including a bottom distribution beam 1, a group of steel pipe column assemblies 3 and a top distribution beam 7; It can be detachably installed on the bearing platform 5; each set of the steel pipe column assembly 3 includes a flanged steel pipe column 32 and a steel pipe column foot 31, wherein the steel pipe column foot 31 is welded to the bottom distribution beam 1, The upper end of the steel pipe column foot 31 is flange-connected with a steel pipe column 32 ;

[0050] The installation and connection in the pipe string foundation structure mostly adopts a detachable connection structure, which realizes the rapid installation and disassembly of the pipe string foundation structure, which is convenient for rapid construction and use. Of course, the method of using the pipe column foundation structure is simple, which saves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com