Heat dissipating device of skid steer loader

A skid steer loader and heat sink technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as narrow maintenance space, and achieve the effect of simple mechanism, improved maintenance performance, and improved maintenance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

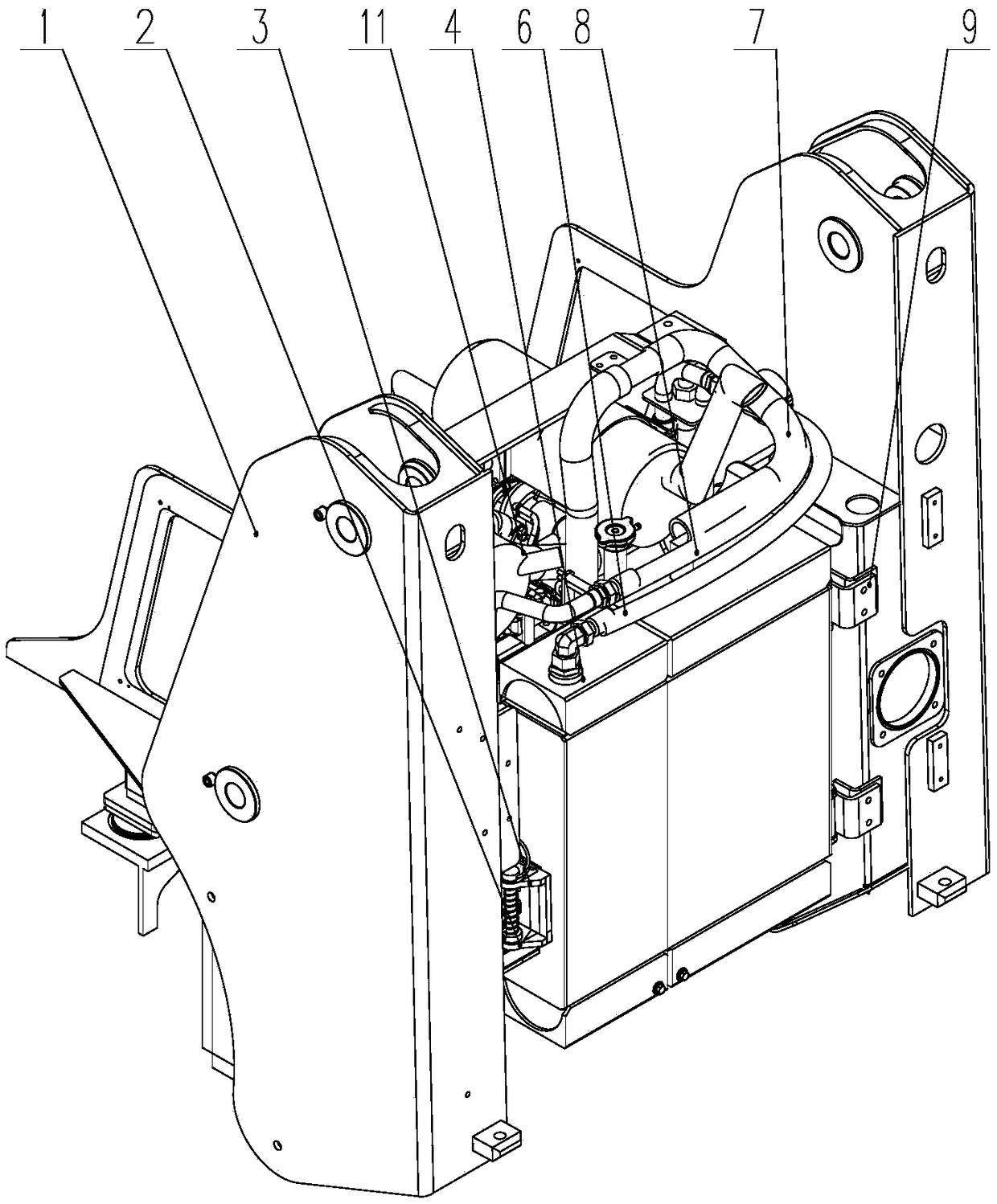

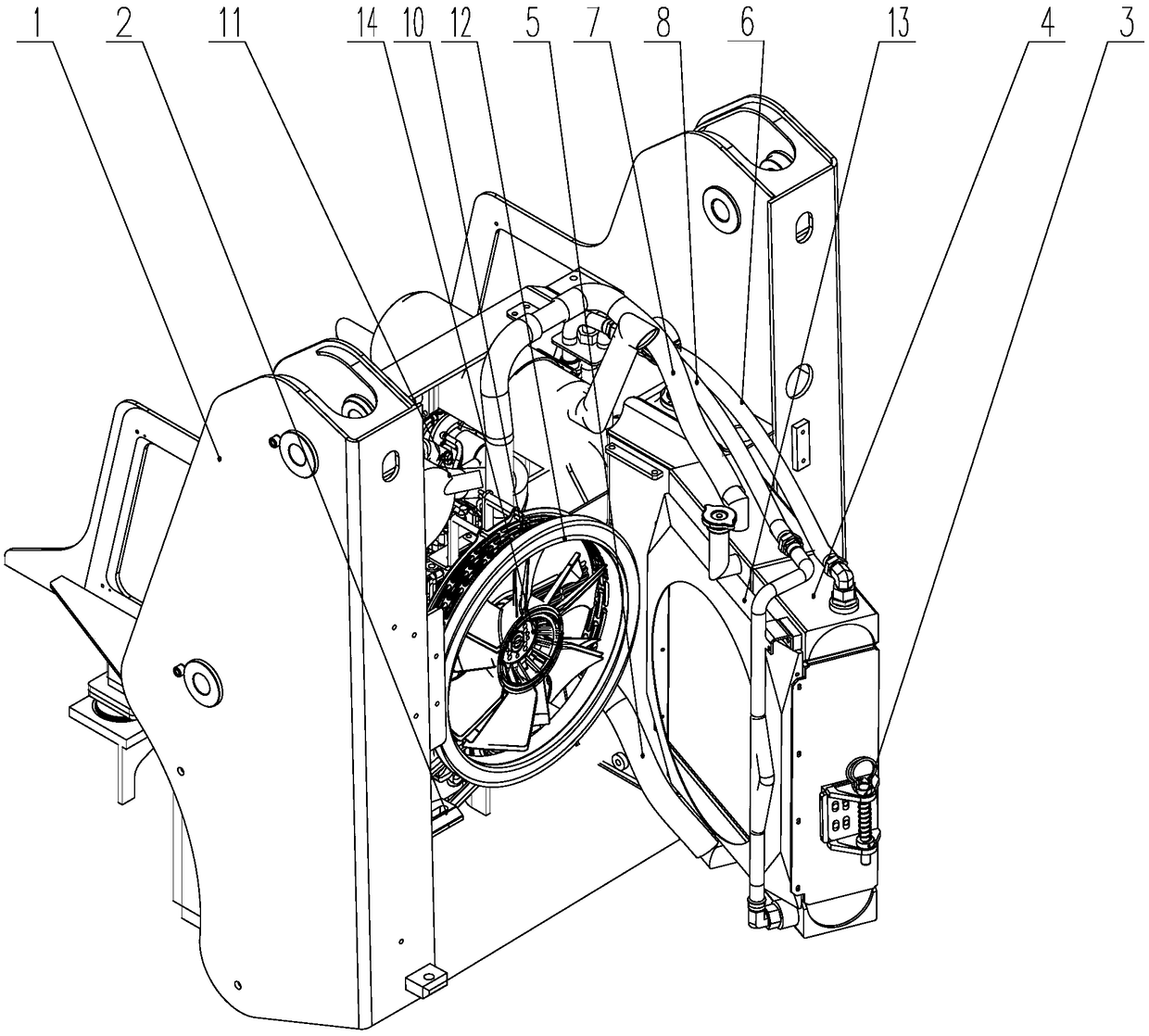

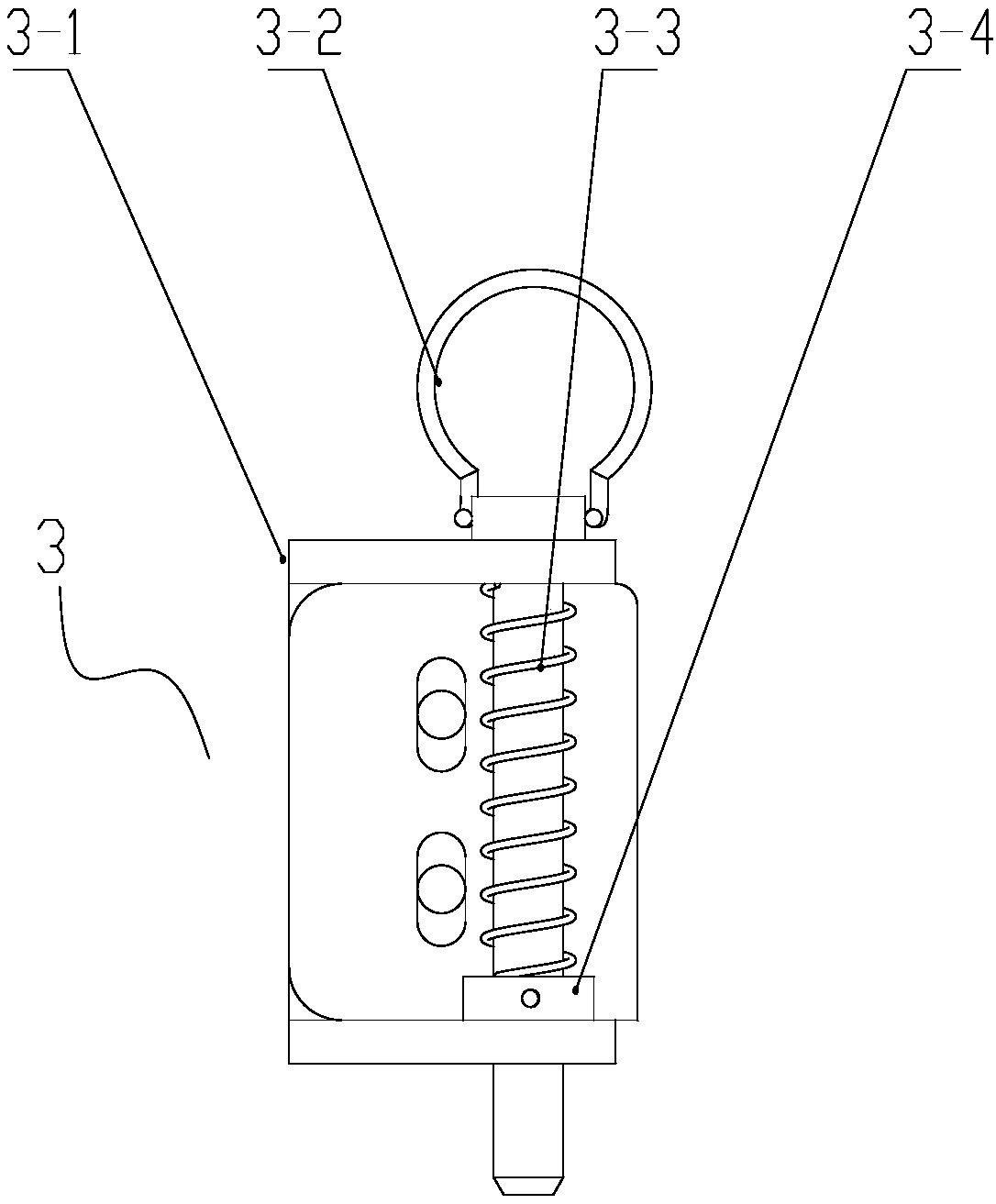

[0025] see figure 1 and figure 2 , the skid steer loader cooling device in the illustration is the preferred solution of the present invention, specifically including the body frame 1, the radiator fixing seat 2, the locking mechanism 3, the radiator 4, the water inlet pipe 5, the oil return pipe 6, the water outlet pipe 7, Oil inlet pipe 8, hinge 9, air guide ring 10, elastic seal 12, air guide cover 13 and cooling fan 14. Wherein, radiator 4 and radiator fan 14 constitute main heat dissipation parts, and the flowing wind that radiator fan 14 produces brings the heat that equipment work such as engine 11 installed between body frame 1 produces in radiator 4 and carries out heat exchange, simultaneously The radiator 4 is arranged in an openable installation manner, and the large space generated by opening the radiator 4 provides space for maintaining the internal engine 11 and other equipment.

[0026] Specifically, the radiator 4 in this embodiment is a water-cooled radiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com