Power amplifier with heat dissipation structure

A technology of power amplifier and heat dissipation structure, applied in power amplifier and other directions, can solve the problems of inconvenient connection, high production cost, circuit short circuit, etc., to ensure the heat dissipation function and effect, improve the heat dissipation effect, and the effect of fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

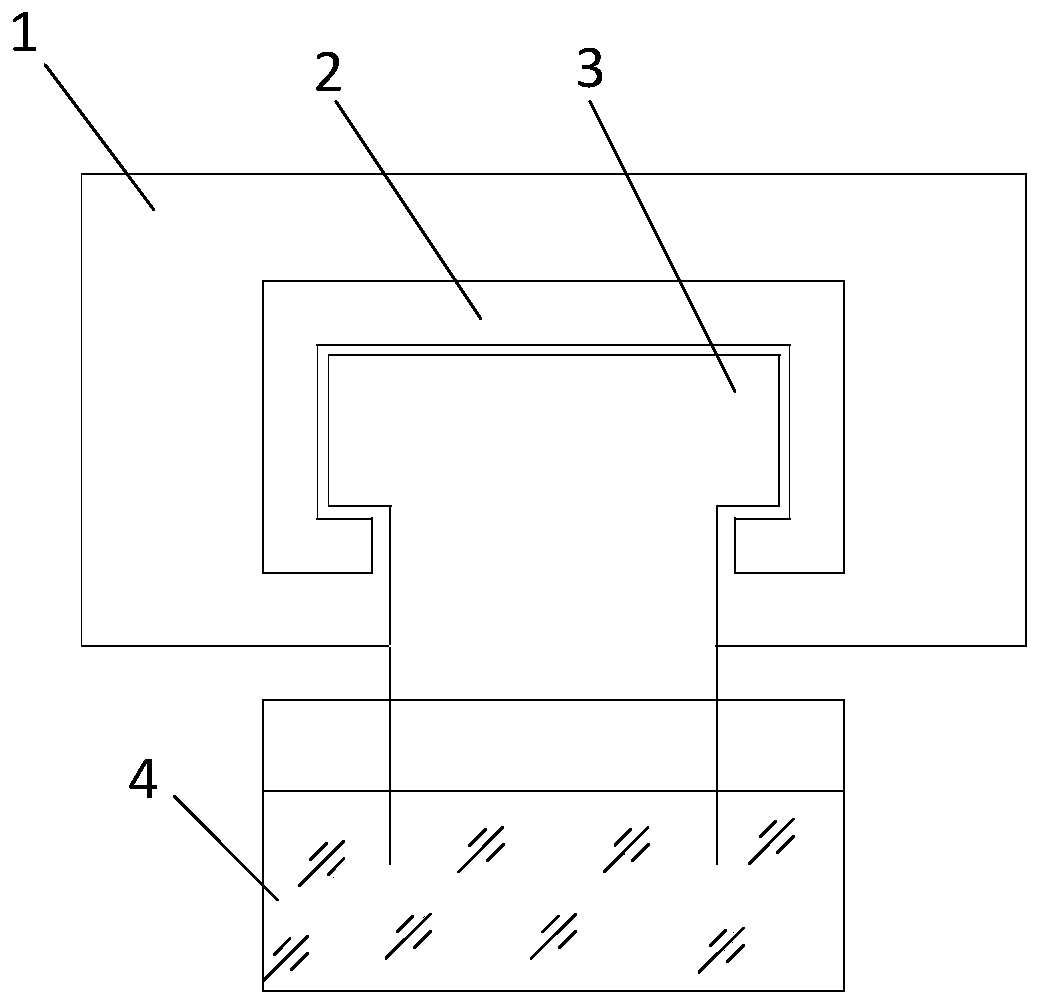

[0027] Such as figure 1 As shown, a power amplifier with a heat dissipation structure includes a power amplifier main body 1, a fixed frame 2, a heat dissipation strip 3 and a heat dissipation medium container 4, the fixed frame 2 is arranged on the outer wall of the power amplifier main body 1, and one end of the heat dissipation strip 3 is fixed In the fixed frame 2 and attached to the outer wall of the power amplifier main body 1, the other end is soaked in the heat dissipation medium container 4, the heat dissipation medium in the heat dissipation medium container 4 forms a capillary phenomenon with the heat dissipation strip 3, and the heat dissipation medium volatilizes from the heat dissipation strip 3 Take away the heat generated by the power amplifier. If necessary, add an electric fan nearby to increase the air flow rate and enhance the heat dissipation effect.

[0028] The heat dissipation strip 3 is provided with an insulating layer on the side of the outer wall o...

Embodiment 2

[0035] Different from Embodiment 1, the fixing frame 2 and the main body of the power amplifier 1 are adhered by self-adhesive, such as 3M adhesive tape, which will not leave sticking marks.

Embodiment 3

[0037] The difference from Embodiment 1 is that the heat dissipation strip 3 is made of hard material, such as a thick metal microporous plate, and the internal holes have capillarity. When the main body of the power amplifier 1 is overhead, the heat dissipation strip of this material can be selected. The material is also more thermally conductive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com