Method for predicting performance of laser glass by using glass material genetic method

A technology of laser glass and glass materials, applied in chemical property prediction, chemical machine learning, chemical data mining, etc., can solve problems such as low efficiency, long research and development cycle, insufficient understanding of glass structure, etc., and achieve accurate prediction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

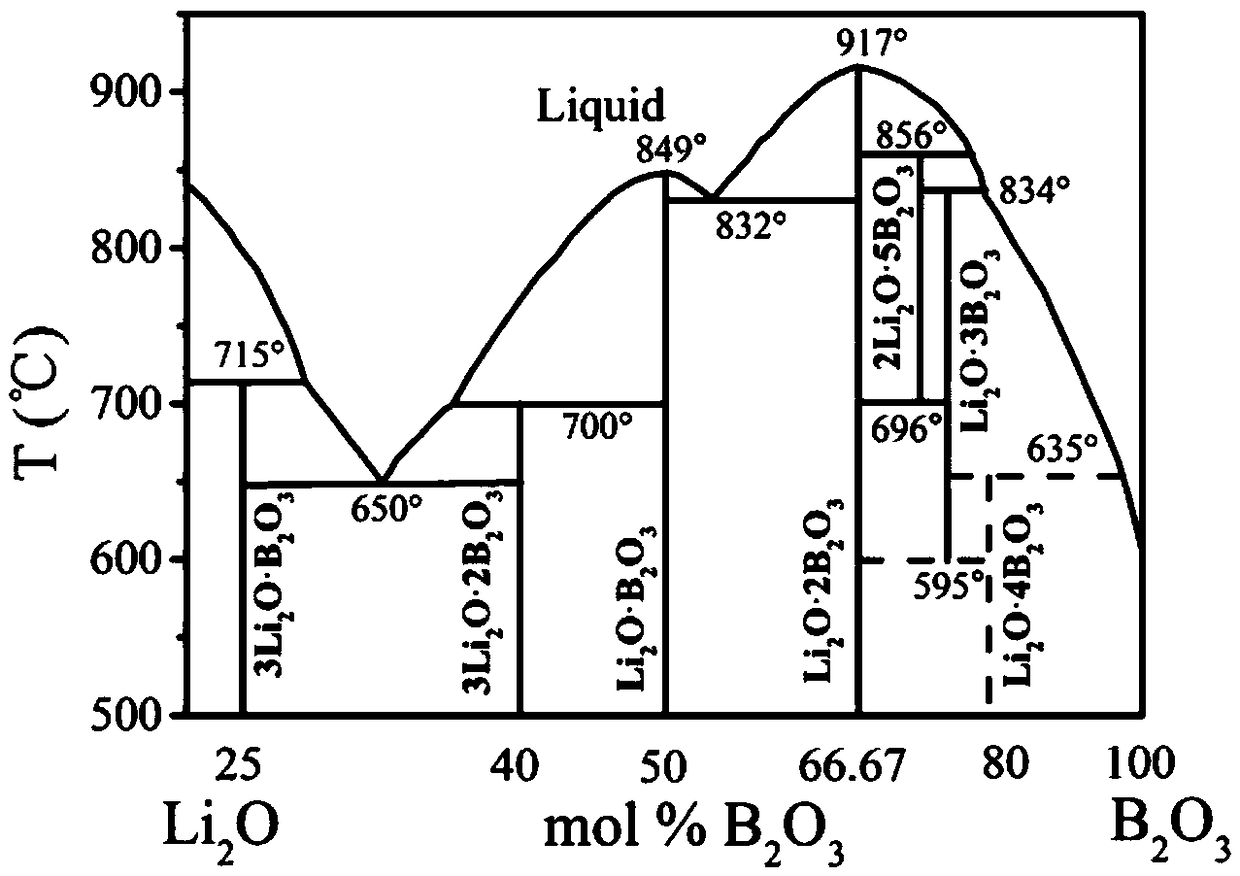

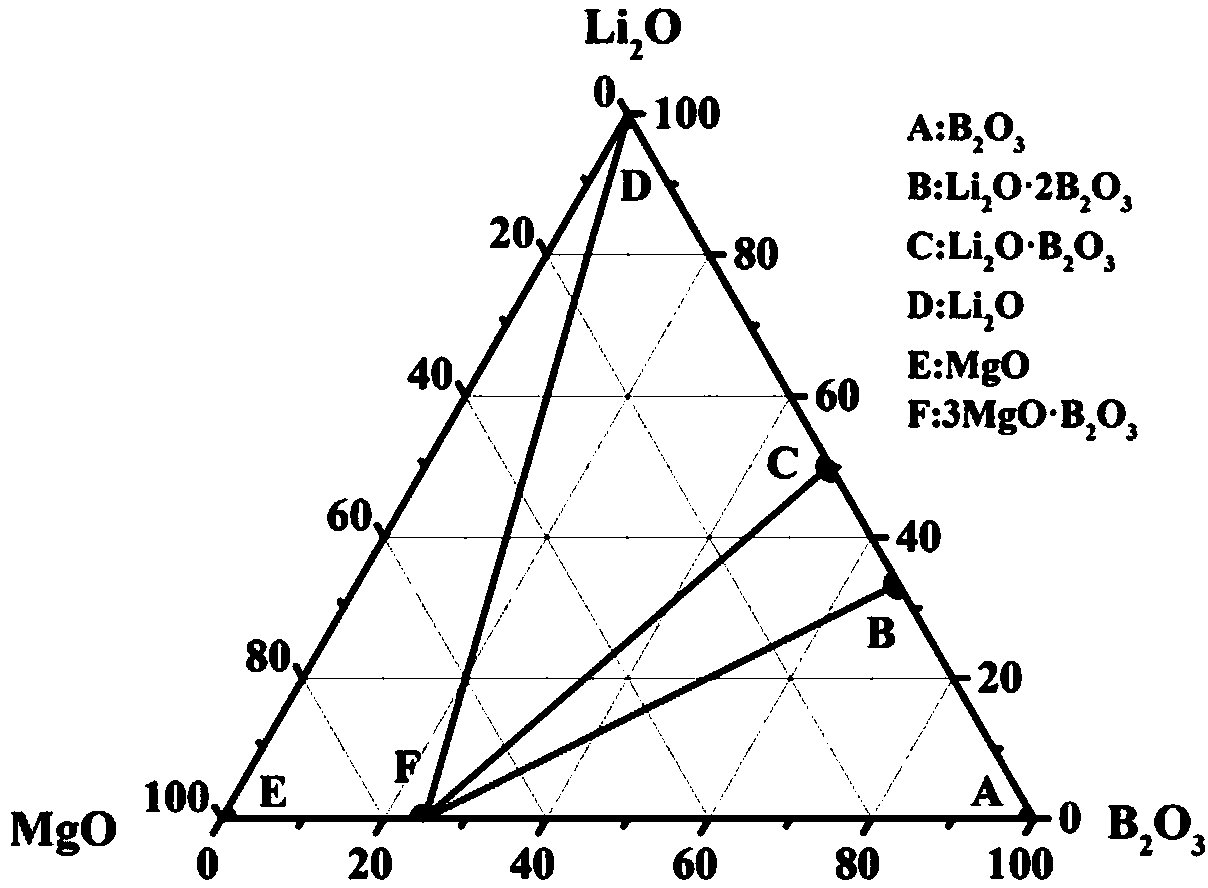

[0025] The target glass that needs to predict the laser performance is: Nd 3+ Doped borate glass, xLi 2 O-(99-x)B 2 O 3 -1Nd 2 O 3 (10≤x≤50mol%) and its xLi 2 O-(99-x-y)B 2 O 3 -yMgO-1Nd 2 O 3 (10≤x≤50mol%, 5≤y≤15mol%).

[0026] Quantitative prediction of Nd using glass gene method 3+ Doped xLi 2 O-(99-x)B 2 O 3 -1Nd 2 O 3 The laser properties, the laser properties here include Nd in glass 3+ ion 4 F 3 / 2 → 4 I 11 / 2 Effective line width of transition, fluorescence half-peak width, fluorescence lifetime, peak emission cross section, Nd 3+ ion 4 F 3 / 2 Energy level radiation lifetime and absorption cross section at 808nm. Taking the consistent molten glassy compound in the corresponding phase diagram of the glass as the target glass material gene, the laser performance of the glass corresponding to the consistent molten glassy compound component in the phase diagram can be used to obtain the laser performance of the target glass. Since the laser performance of the consistent molten gl...

Embodiment 2

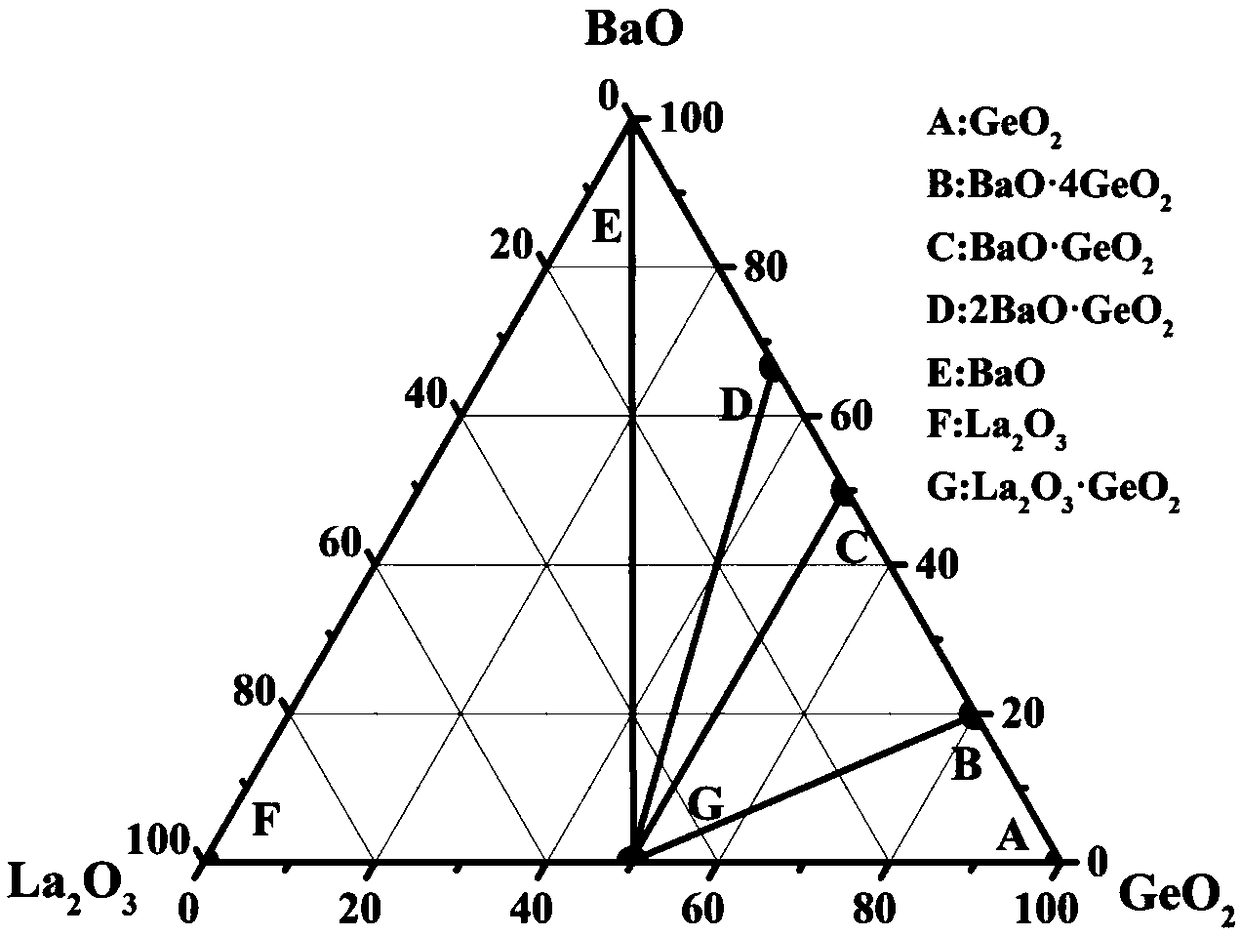

[0069] Glass composition that needs to predict laser performance: Tm 3+ Doped germanate glass, (100-x-y)GeO 2 -xBaO-yLa 2 O 3 (5≤x≤50mol%, 0≤y≤15mol%).

[0070] The embodiment is basically the same as that in Example 1, except that the glass component is replaced with germanate glass, and the rare earth ion is Tm 3+ , Predicted Tm 3+ Doped (100-x-y)GeO 2 -xBaO-yLa 2 O 3 (5≤x≤50mol%, 0≤y≤15mol%) laser performance of glass, including Tm 3+ : 3 F 4 → 3 H 6 The effective line width of the transition, the fluorescence half-height width, the fluorescence lifetime, and the stimulated emission cross section. Specific steps are as follows.

[0071] (1) Looking for GeO 2 -BaO-La 2 O 3 It is found that there is no complete phase diagram data for the corresponding phase diagram of the glass. At this time, we can find the corresponding binary phase diagram, and divide the triangular area with the consistent molten glassy compound in the binary phase diagram as the apex. The principle of division...

Embodiment 3

[0076] Glass component that needs to predict laser performance: Yb 3+ Doped phosphate glass (100-x-y)P 2 O 5 -xAl 2 O 3 -yLa 2 O 3 (0≤x≤20mol%, 0≤y≤15mol%).

[0077] The embodiment is basically the same as in Example 1, except that the glass component is replaced with phosphate glass, and the rare earth ion is Yb. 3+ , Forecast Yb 3+ Doped (100-x-y)P 2 O 5 -xAl 2 O 3 -yLa 2 O 3 (0≤x≤20mol%, 0≤y≤15mol%) laser performance of glass, including Yb 3+ : 2 F 5 / 2 → 2 F 7 / 2 The effective line width of the transition, the fluorescence half-height width, the fluorescence lifetime, and the stimulated emission cross section. Specific steps are as follows:

[0078] (1) Divide P 2 O 5 -Al 2 O 3 -La 2 O 3 The corresponding phase diagram of the glass.

[0079] (2) Find Yb 3+ Doped (100-x-y)P 2 O 5 -xAl 2 O 3 -yLa 2 O 3 The glass formula, and the composition of the glass is represented by three adjacent molten glassy compounds.

[0080] (3) Calculate the laser performance corresponding to the same molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com