New energy vehicle power source controllable heating piece

A new energy vehicle, controllable technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as danger, battery heating, power lithium battery discharge performance, and charging acceptance capacity decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

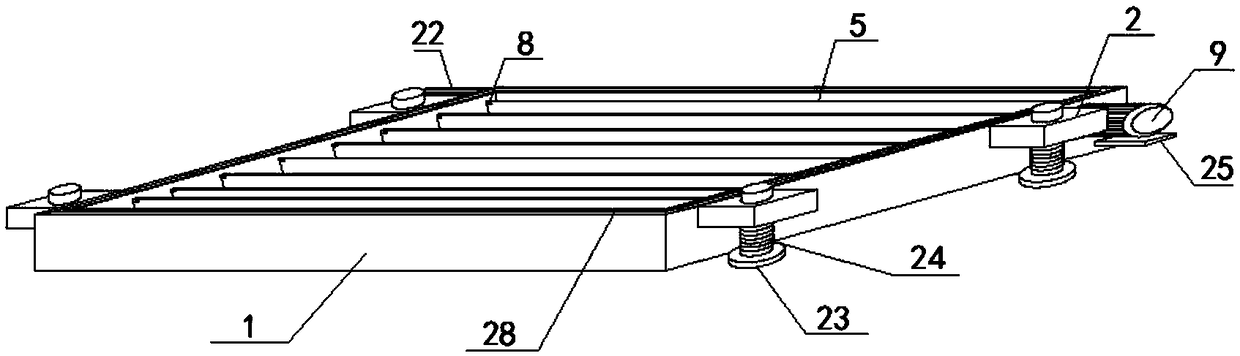

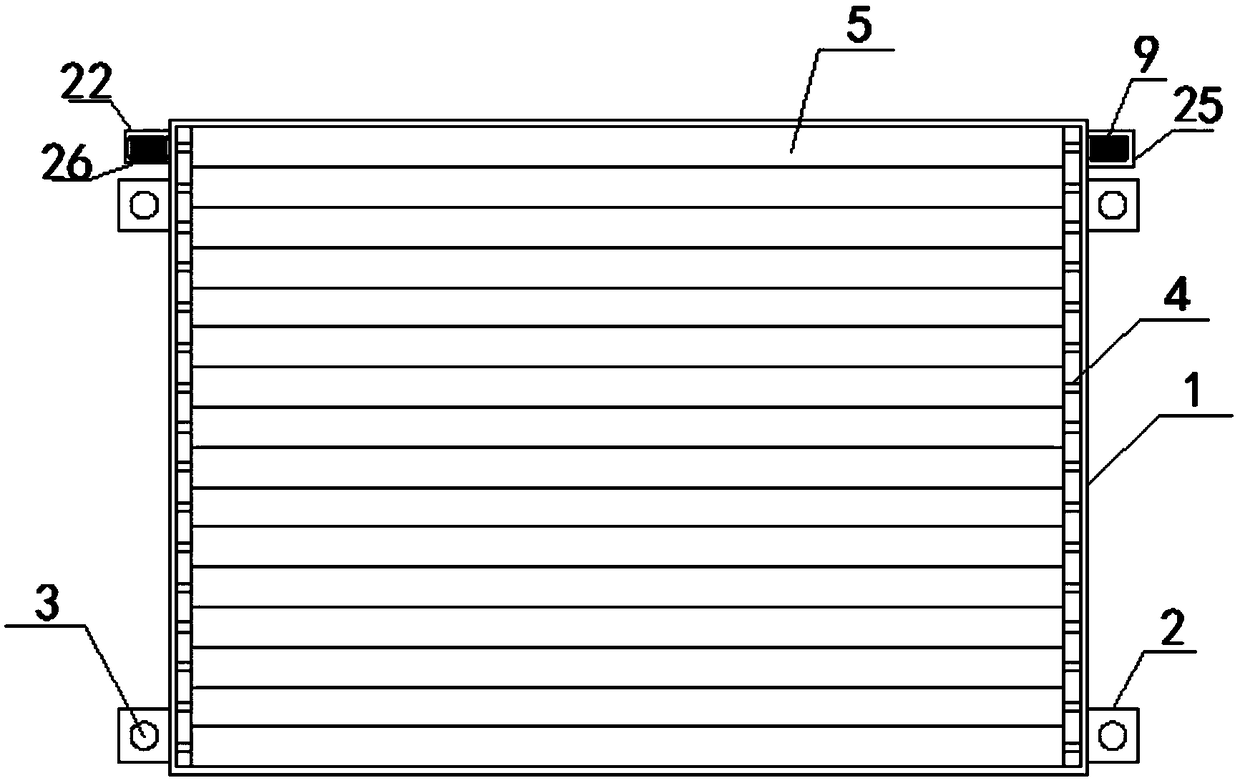

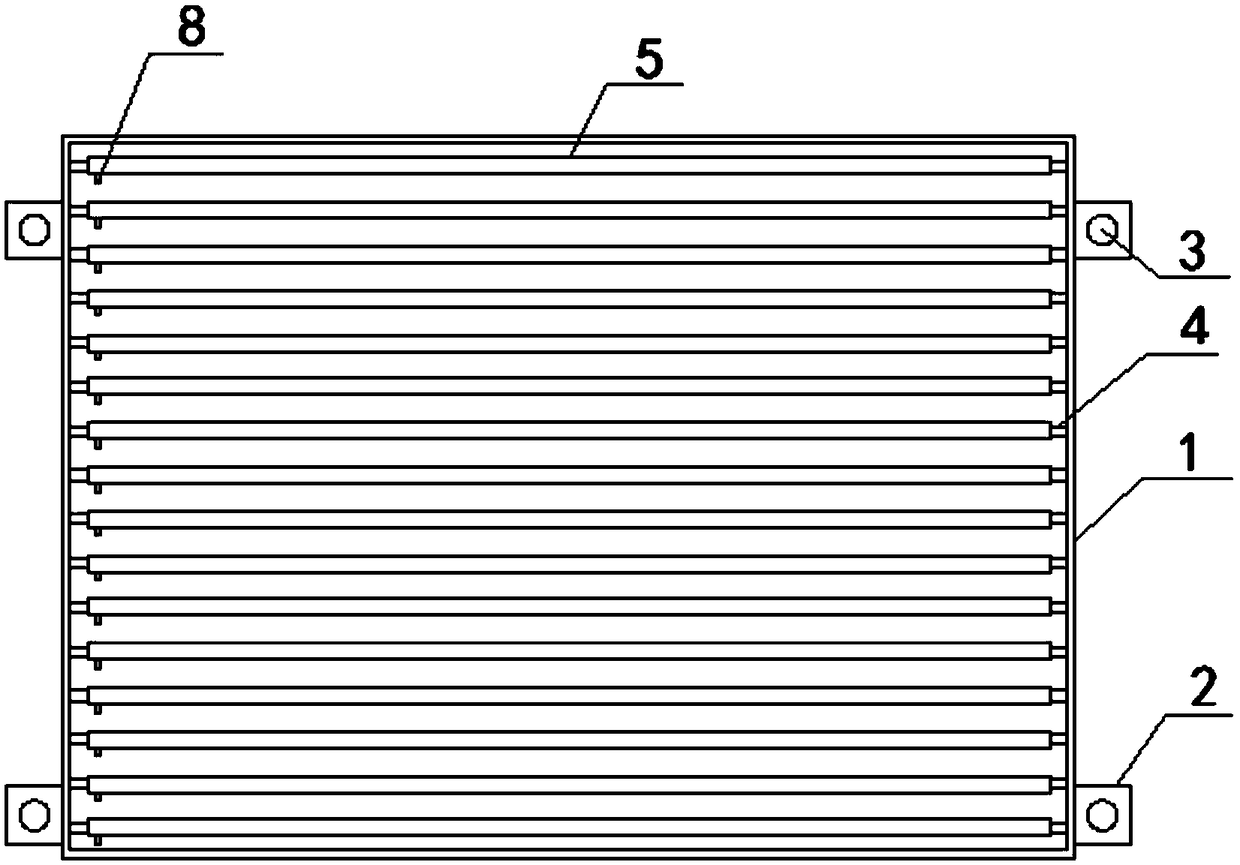

[0029] refer to Figure 1-8 , a new energy vehicle power supply controllable heating sheet, including a return-shaped metal frame 1, the inside of the return-shaped metal frame 1 is a hollow structure, and the outer side of the return-shaped metal frame 1 is vertically welded with a fixed connection block 2, fixedly connected The middle of the block 2 is provided with a fixed through hole 3, and the fixed through hole 3 runs through the upper and lower sides of the fixed connection block 2, and a rotating column 4 is inserted between the inner side walls of the circular metal frame 1, and the rotating column 4 is far away from the circular metal frame. One end of the frame 1 is welded on the central axis of the metal conductive sheet 5, the heating wires 7 are evenly arranged in a Z shape inside the metal conductive sheet 8, and the rotating column 4 is left-right symmetrical on the inner side wall of the circular metal frame 1, The rotating column 4 is welded with a metal con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com