Closed-type wiring terminal with waterproof structure

A waterproof structure and terminal technology, applied in the connection, the parts of the connection device, the fixing/insulating contact member, etc., can solve the problems of insufficient fixing, high maintenance cost, poor sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

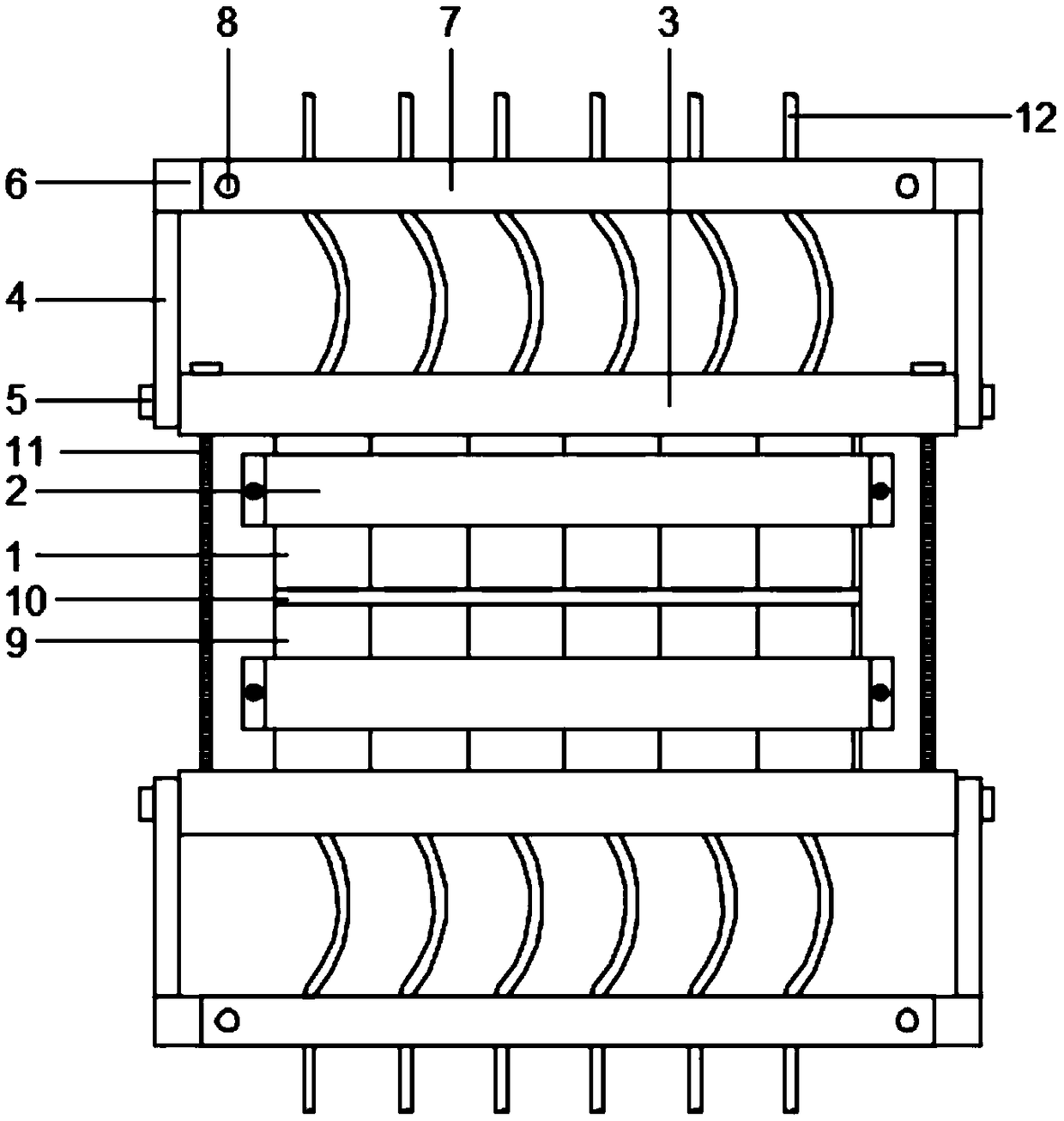

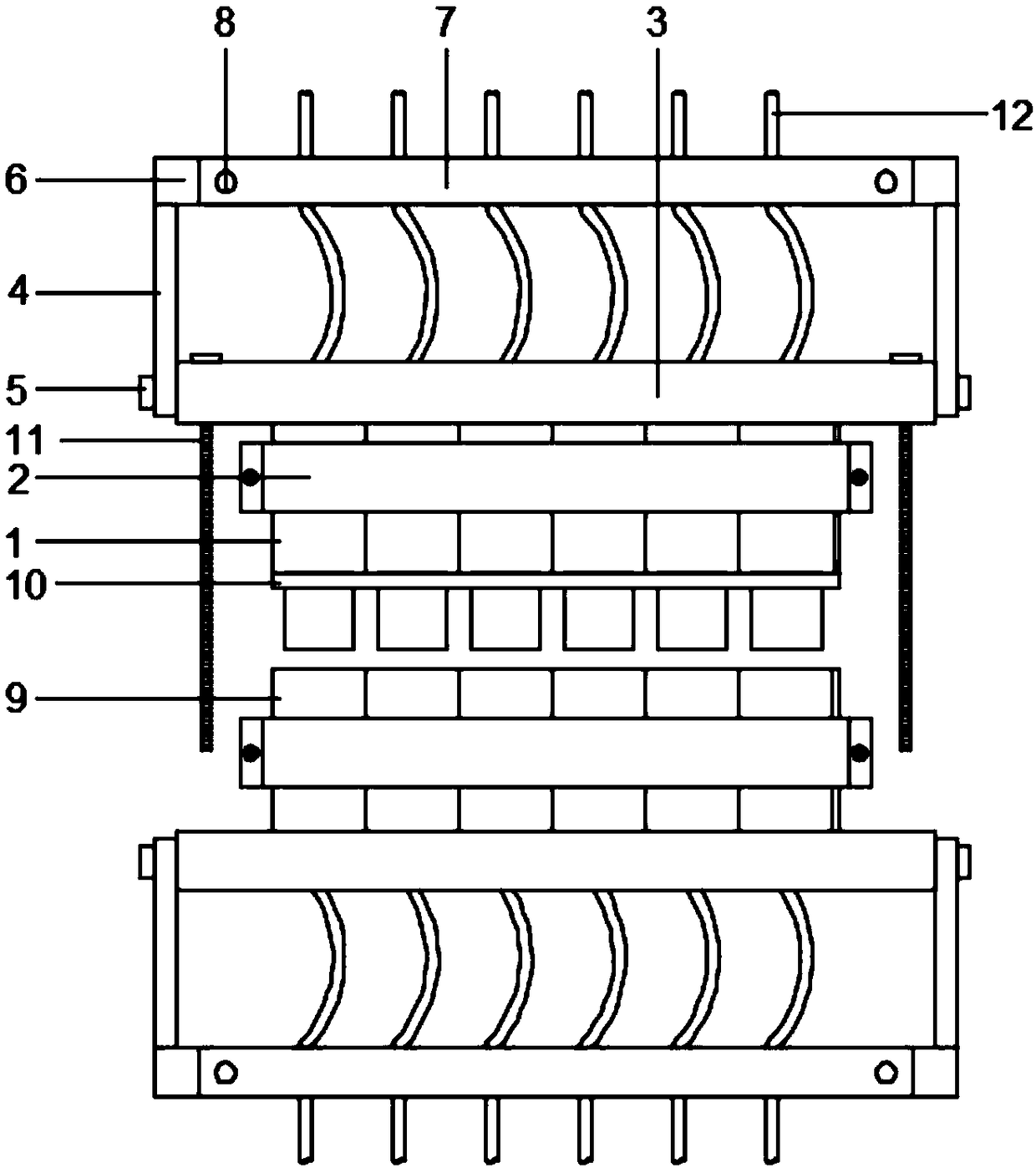

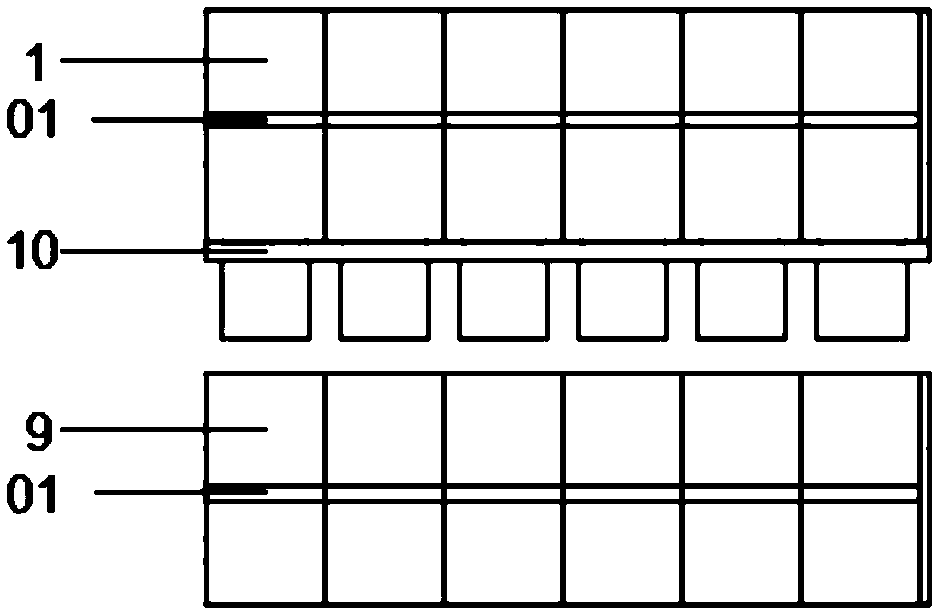

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a sealed terminal with a waterproof structure, including: terminal plug 1, semicircular groove 01, clamp 2, semicircular protrusion 201, rectangular block 3, rectangular groove 301, circular hole 302, rectangular Plate 4, fixing bolt A5, clamping plate A6, clamping groove 02, clamping plate B7, fixing bolt B8, terminal socket 9, rubber washer 10, fixing bolt C11 and wire 12; the left end of terminal plug 1 has a slide groove , and the right end surface of the terminal plug 1 is provided with a sliding protrusion; there are six terminal plugs 1 in total, and a semicircular groove 01 is provided at the center of the front end of each terminal plug 1; the clamp 2 is socketed on the six On the terminal plug 1, a semicircular protrusion 201 is welded on the inner wall of the clamp 2; a rectangular groove 301 is provided on the bottom surface of the rectangular block 3, and the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com