a plate moving machine

A mobile machine and mobile mechanism technology, applied in the field of mobile machines, can solve problems such as easy frostbite, high difficulty coefficient of work, easy soreness and swelling of hands, and achieve the effects of preventing back and forth sliding, enhancing the scope of application, and saving manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

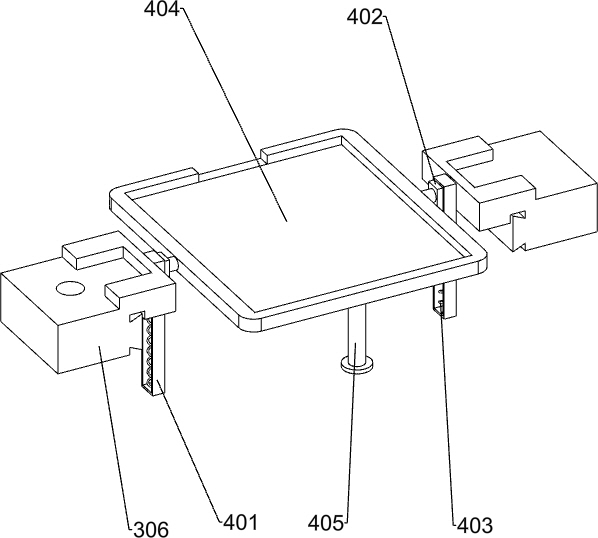

[0053] A plate mover such as figure 1 As shown, it includes a bottom plate 1, a mounting plate 2, a moving mechanism 3 and a placing mechanism 4. The top of the bottom plate 1 is provided with mounting plates 2 on the left and right sides, and the top of the mounting plate 2 is provided with a moving mechanism 3. The right part of the moving mechanism 3 and The top of the base plate 1 is connected, and a placing mechanism 4 is arranged between the moving mechanisms 3 on the left and right sides.

[0054] When it is necessary to use the machine to drive the plate body 7 to catch the milk tea crushed ice, first place the plate body 7 on the placing mechanism 4, then start the moving mechanism 3, the moving mechanism 3 drives the placing mechanism 4 to move back and forth, and the placing mechanism 4 drives the plate body 7 Move back and forth to make the plate body 7 evenly catch the milk tea crushed ice, then close the moving mechanism 3, remove the plate body 7 with the milk t...

Embodiment 2

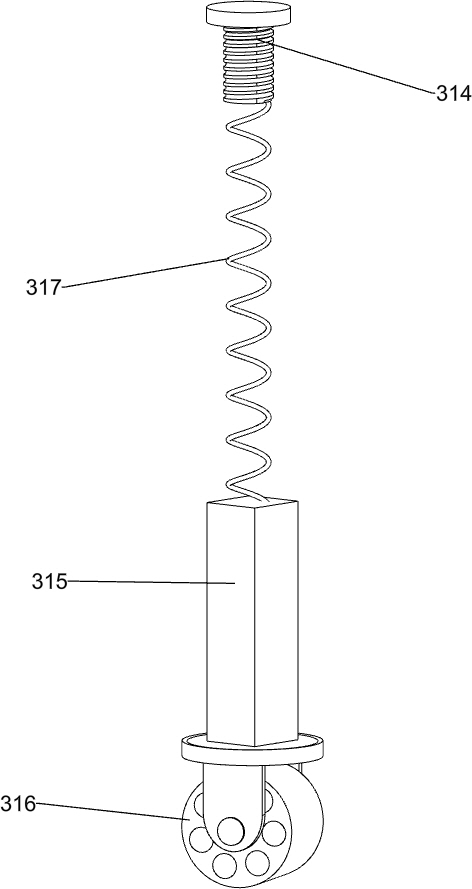

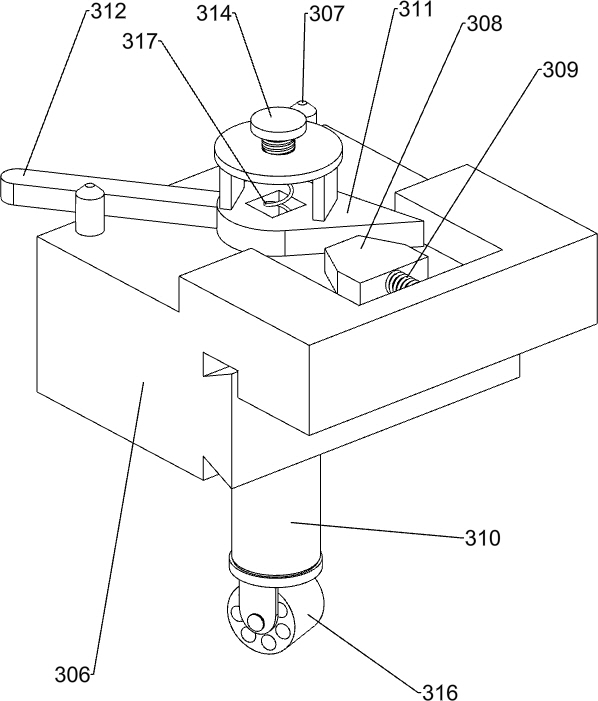

[0056] On the basis of Example 1, as Figure 2-6As shown, the moving mechanism 3 includes a special-shaped plate 301, a rotating rod 302, a roller 303, a motor 304, a first sliding rail 305, a first sliding block 306, a limit rod 307, a clamping plate 308, a first spring 309, a cylinder 310 , turning plate 311, swing plate 312, disc 313, first bolt 314, square rod 315, wheel 316 and second spring 317, special-shaped plates 301 are provided on the front and rear sides on the right side of the top of the bottom plate 1, and the middle of the special-shaped plate 301 is rotated. There is a rotating rod 302, a roller 303 is sleeved on the rotating rod 302, and the roller 303 is located between the special-shaped plates 301 on the front and rear sides. Connection, the tops of the mounting plates 2 on the left and right sides are provided with first slide rails 305, the first slide rails 305 are slidably provided with first sliders 306, and the top of the first slide block 306 on th...

Embodiment 3

[0061] On the basis of Example 2, as Figure 7-9 As shown, it also includes a toggle mechanism 5. The toggle mechanism 5 includes a third slide rail 501, a third slider 502, a second bolt 504, a vertical rod 505 and a toggle rod 506. The top right side of the bottom plate 1 is provided with a third Three slide rails 501, the third slide rail 501 is located on the right side of the special-shaped plate 301, the third slide rail 501 is slidably provided with a third slide block 502 at the front and rear, and an opening 503 is opened on the right side of the third slide rail 501, and the third slide rail 501 The right side of the block 502 is connected with second bolts 504 by means of bolts, and the second bolts 504 pass through the opening 503 .

[0062] Adjust the toggle mechanism 5 according to the size of the plate, first loosen the second bolt 504, then move the third slider 502 back and forth, after finding a suitable position, tighten the second bolt 504, when the wheel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com