Online embossing method for PVC floor and special production device for online embossing method

A production device and embossing technology, applied in the field of PVC floor production and processing, can solve problems such as low production efficiency of embossing processing, and achieve the effects of solving low production efficiency, saving energy and reducing operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

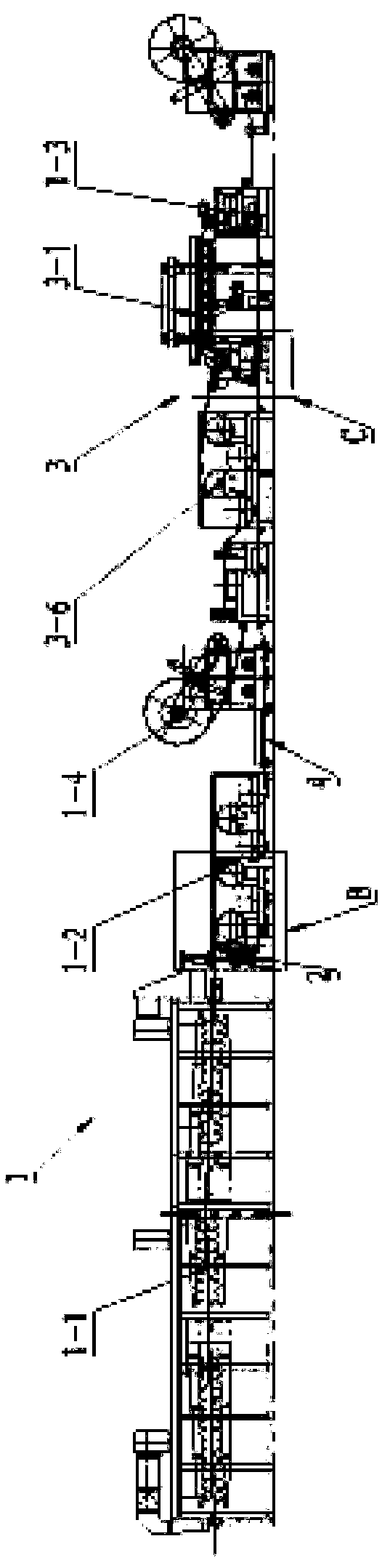

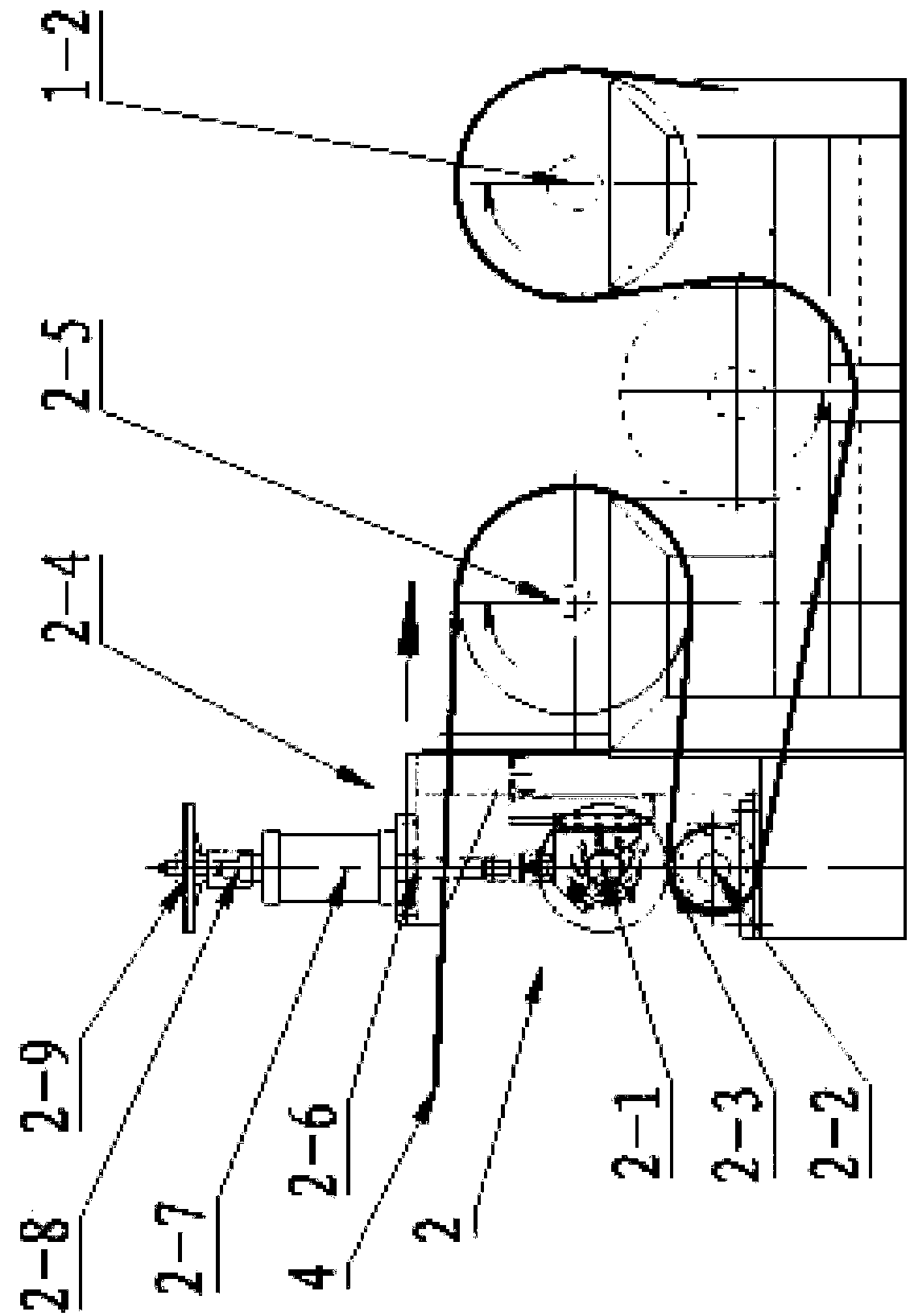

[0020] Embodiment 1 of the online embossing method for PVC flooring of the present invention: This embodiment is suitable for the production process of processing PVC flooring by using a smooth front release paper as a carrier and applying a coating method. The method comprises the following steps: Step 1, after the PVC floor molding material is coated on the surface of the release paper, the release paper coated with the PVC floor layer is subjected to various processes until it is foamed in an oven; Step 2, through at least one pair The roller embosses on the back of the PVC floor layer away from the release paper, and the outer circumference of one of each pair of rollers in all pairs of rollers is provided with a raised back embossing corresponding to the embossing that needs to be printed on the back of the PVC floor layer. Step 3, cooling the surface of the release paper coated with PVC flooring; Step 4, peeling the PVC flooring from the front of the release paper; Step 5...

Embodiment 2

[0022] Embodiment 2 of the online embossing method for PVC flooring according to the present invention: this embodiment is suitable for the embossing method that the frontal embossing of PVC flooring is directly printed through the raised frontal embossing on the front side of the release paper. The difference from Example 1 of the online embossing method for PVC floor is that step 4 and step 5 are removed, but the front side of the release paper is processed with protrusions corresponding to the patterns that need to be printed on the front side of the PVC floor layer Front pattern, before step 3, print the front raised pattern on the release paper on the front of the PVC floor.

[0023] In the above-mentioned embodiments, the online embossing method of PVC flooring is suitable for the production method of PVC flooring using release paper as a carrier. In other embodiments, when the production process of PVC flooring does not require release paper as a carrier, but When the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com