Packaging bag and production process thereof

A production process and packaging bag technology, applied in the field of packaging bags and the production process thereof, can solve the problems of poor ventilation effect, high production difficulty, leakage, etc., and achieve the effects of simple production process, strong practicability and good ventilation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

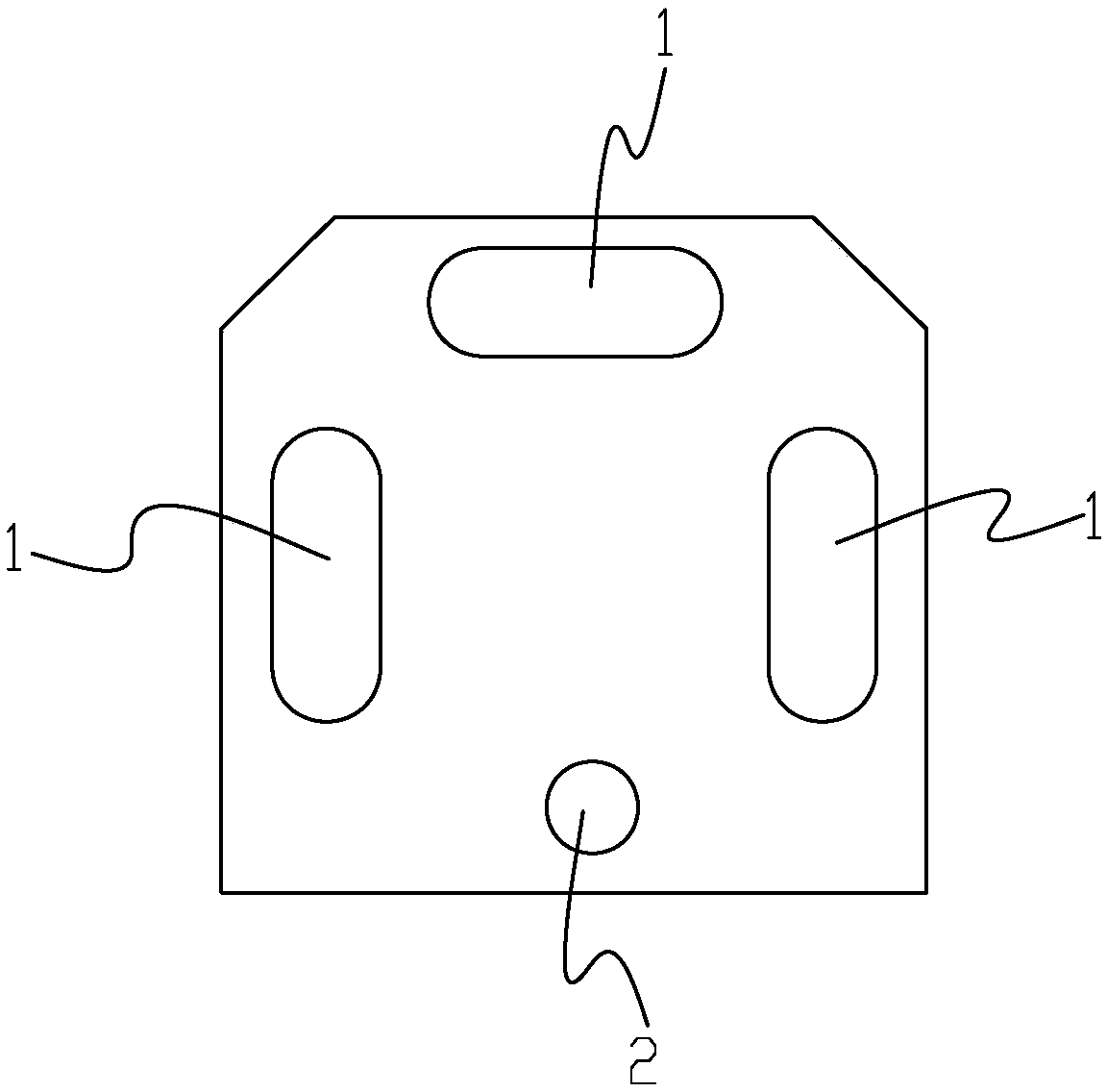

[0026] Please refer to figure 1 , the first embodiment of the packaging bag of the present invention, including the front and the back, the left and right sides and the upper edge of the front and the back are heat-sealed together and a hole is punched in the packaging area to form a handle hole 1 . The lower bottom edges of the front and back are indirectly heat-sealed together through the packaging bottom film, and the opposite sides of the packaging bottom film are heat-sealed with the lower bottom edges of the front and back respectively. After heat sealing, a liquid-filled chamber is formed between the front and back. The front side is provided with charging holes 2, and the back side is a complete surface. After the food factory purchases the packaging bag, a water nozzle can be added to the charging hole 2 .

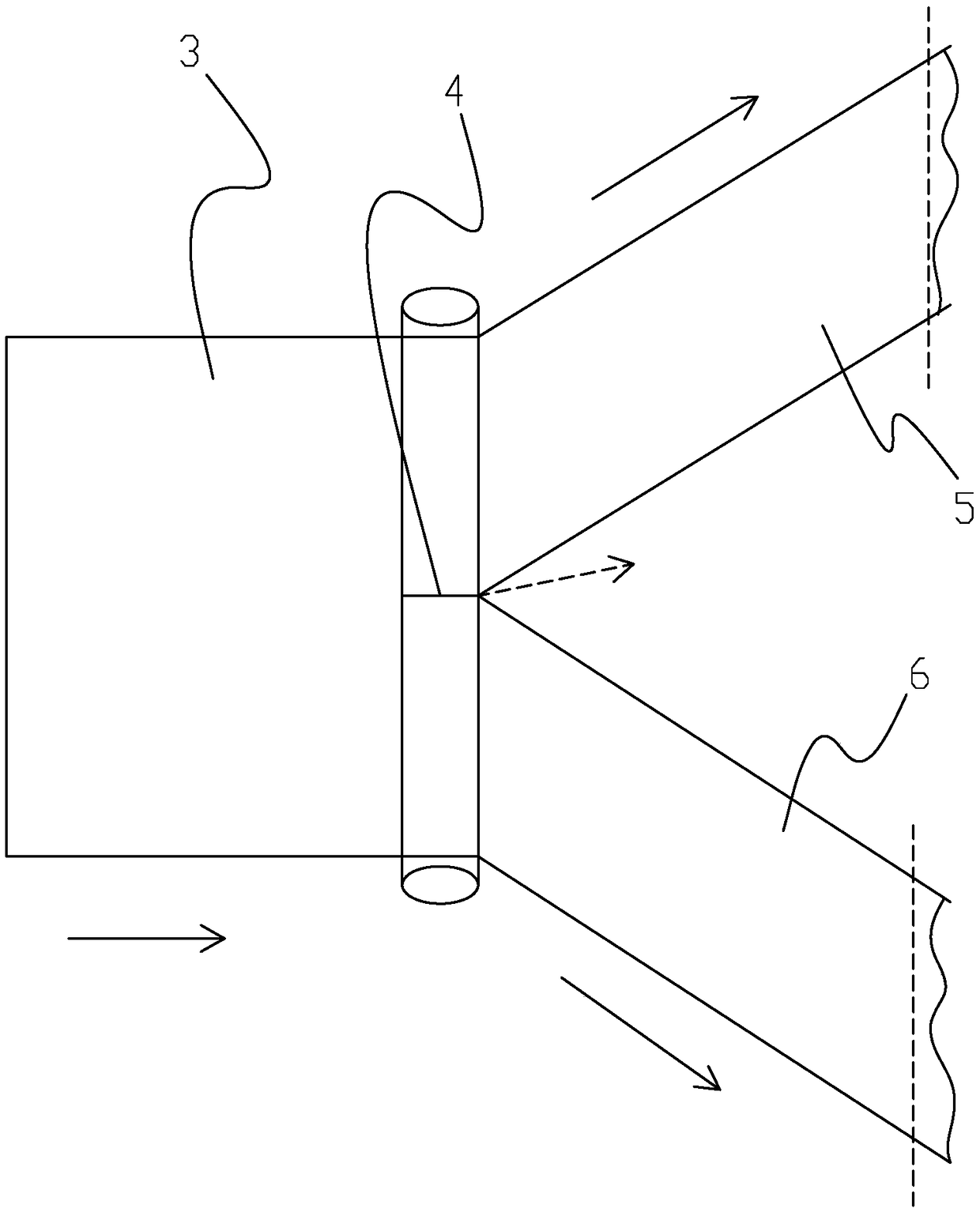

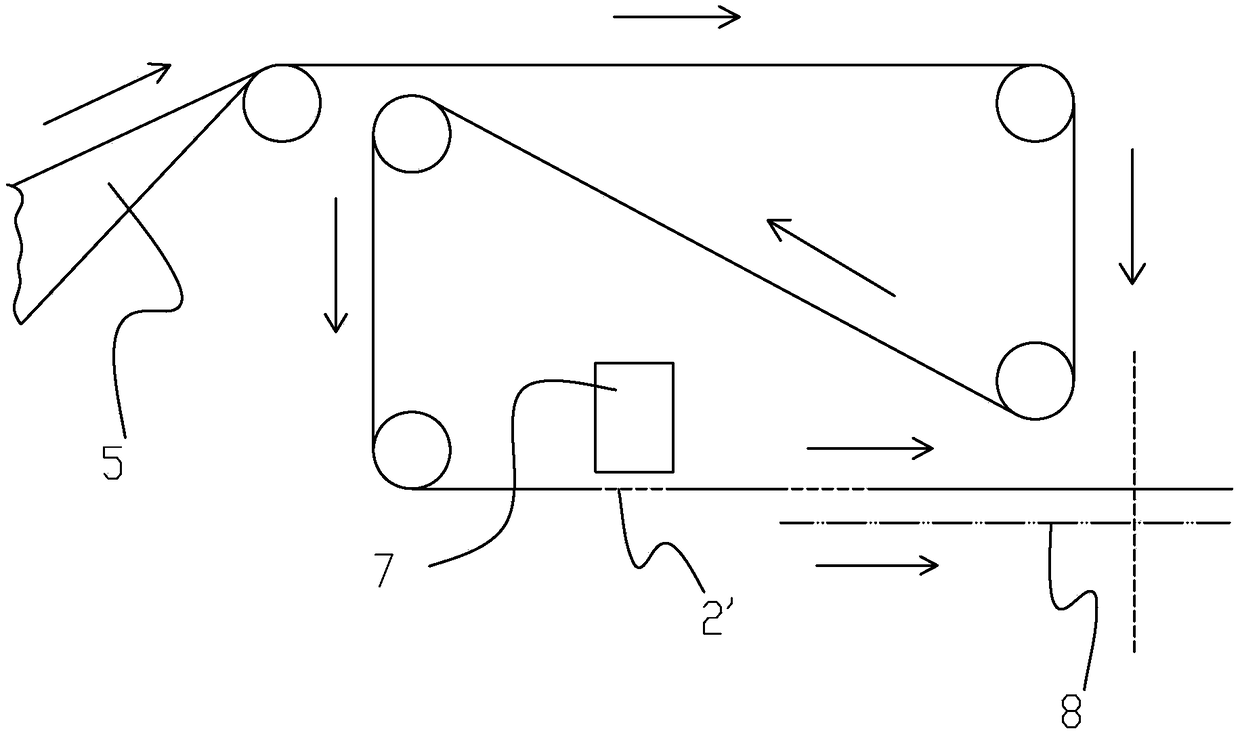

[0027] Please refer to figure 2 To Fig. 5, the first embodiment of the packaging bag production process of the present invention is used to produce figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com