A non-stop intelligent phase splitter for AC electrified railway

A technology for electrified railways and phase splitters, applied in power lines, vehicle components, transportation and packaging, etc., can solve the problems of high cost, difficulty, and large traction current of twisted-pair insulated cables, and reduce construction difficulty and fixed investment Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

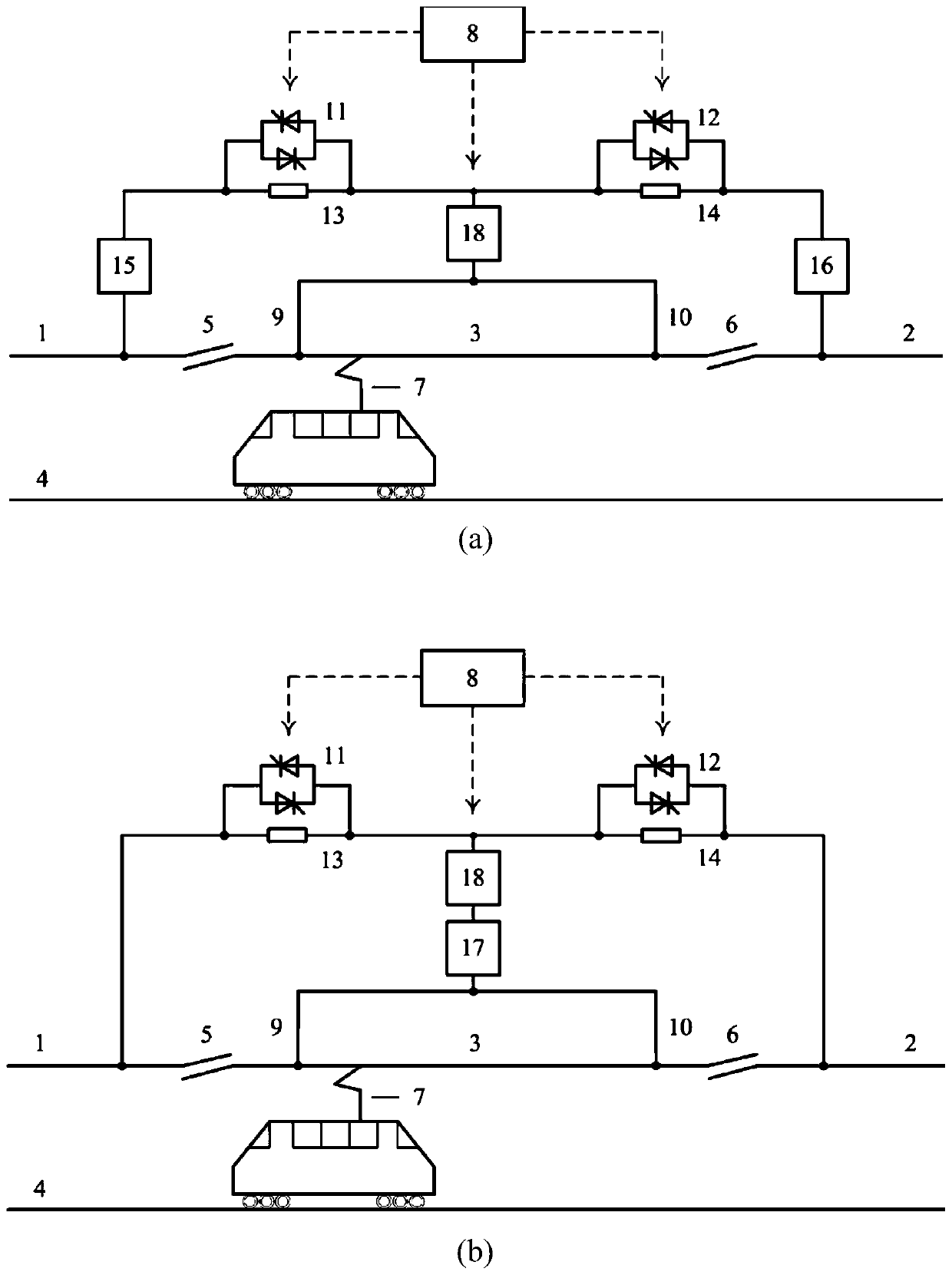

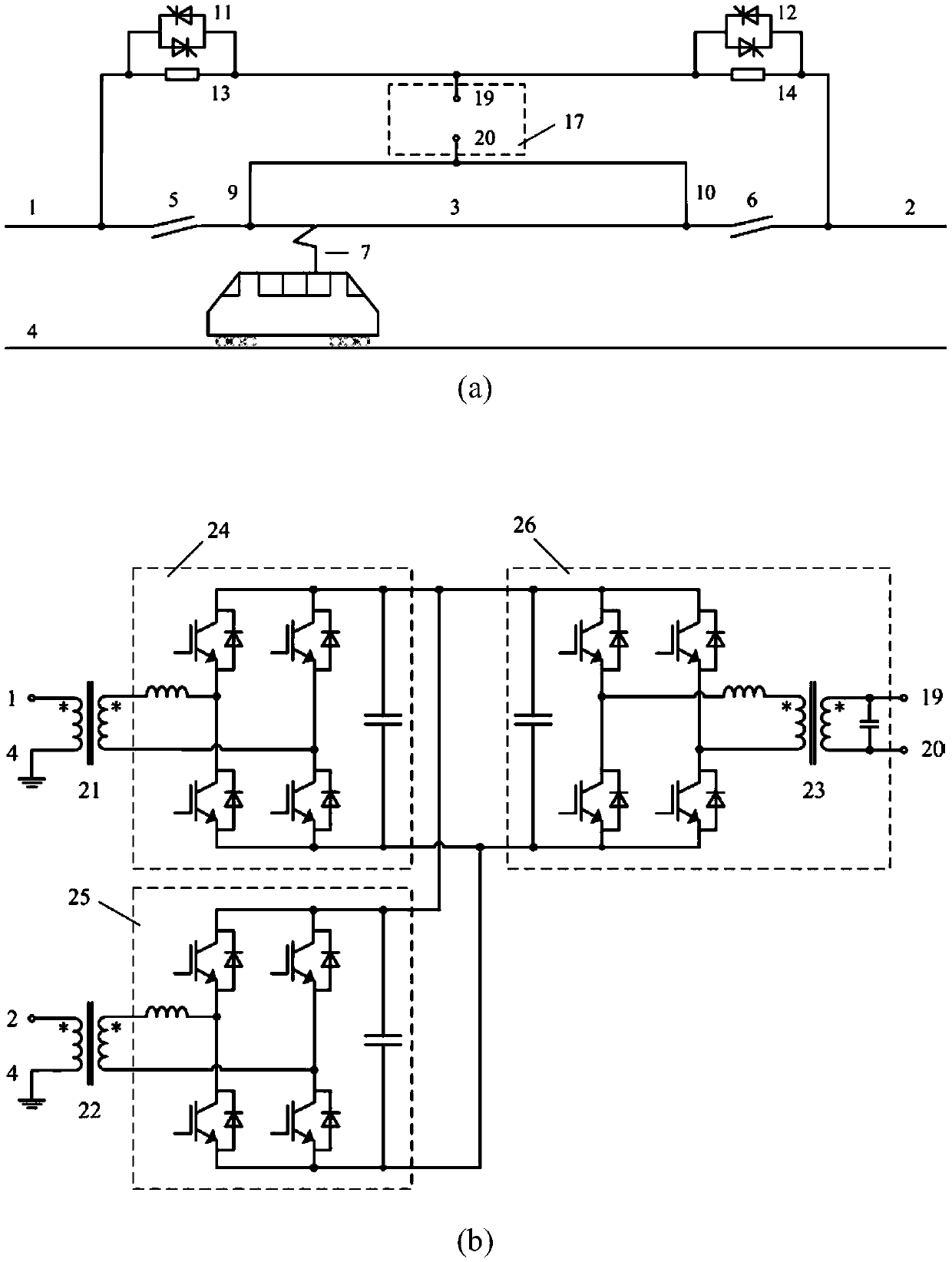

[0041] see figure 1 (a), the AC electrified railway non-stop intelligent phase splitter of the present invention comprises two fast switches 11, 12 and parallel impedances 13, 14 at both ends thereof, two arc-extinguishing adjustable power supplies 15, 16, and a step-shift phase shifter Power supply 18, two connecting wires 9 and 10 in the neutral zone, two fast switches and connecting wires between the arc-extinguishing adjustable power supply and the power supply arm, and an intelligent phase splitter control unit 8 with the function of identifying the position of the train pantograph; A current sensor is installed on each quick switch 11,12 and each neutral zone connection wire 9,10; a voltage sensor is installed on each quick switch 11,12 both sides.

[0042] The current sensor, voltage sensor, and fast switches 11, 12 installed in the above device, the drive control unit of the arc-extinguishing adjustable power supply 15, 16 and the step-shift power supply 18 are all con...

Embodiment 2

[0050] see figure 1 (b), the AC electrified railway non-stop intelligent phase splitter of the present invention comprises two fast switches 11,12 and parallel impedances 13,14 at both ends thereof, an arc-extinguishing adjustable power supply 17, a step-shifting power supply 18, two The connecting wires 9 and 10 in the neutral area, the connecting wires between the two quick switches and the power supply arm, and the intelligent phase splitter control unit 8 with the function of recognizing the position of the train pantograph; each quick switch 11, 12 and each neutral Current sensors are installed on the connecting wires 9 and 10 in the district; voltage sensors are installed on both sides of each quick switch 11 and 12.

[0051] The current sensor, voltage sensor, and fast switches 11 and 12 installed in the above device, the arc-extinguishing adjustable power supply 17, and the drive control unit of the step-shift power supply 18 are all connected to the intelligent phase ...

Embodiment example 1

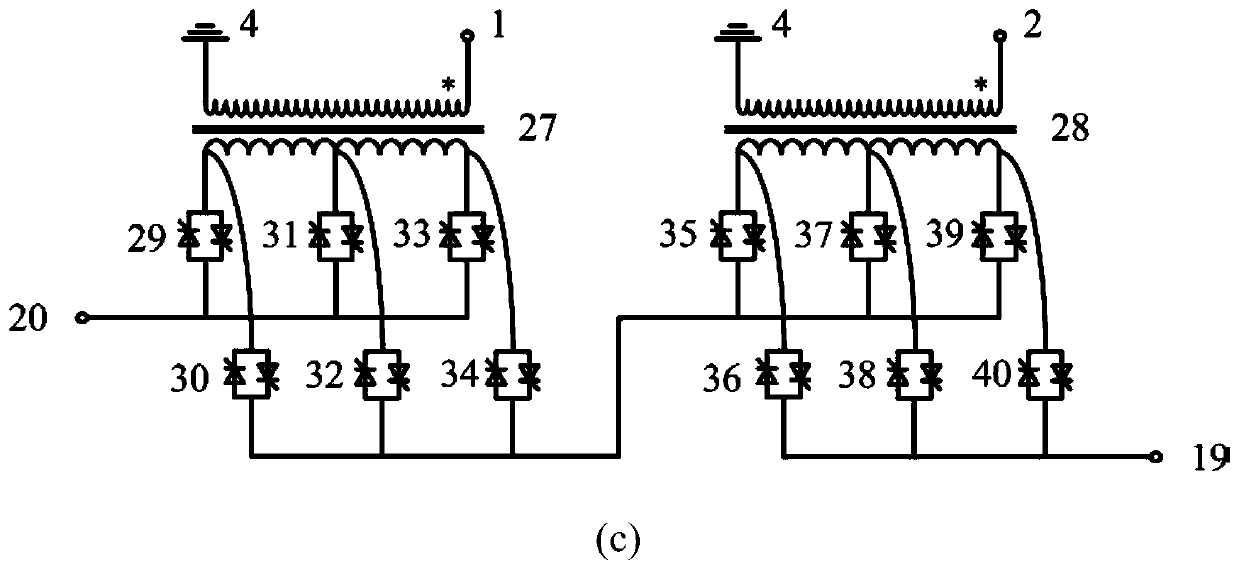

[0069] In the first implementation case, the step-shift power supply can generate an intermediate voltage whose two phases are between the voltage of the first power supply arm 1 and the voltage of the second power supply arm 2, such as image 3 (a) shown. In this implementation case, the topological circuit of the stage-shifted power supply 18 includes two input transformers 41, 42, four transfer switches 43, 44, 47, 48, and parallel impedances 45, 46 at both ends of the transfer switches 43, 44; Voltage sensors and current sensors (not shown in the figure) are all installed on the transfer switches 43, 44, 47, 48. The current sensor installed in the above device, the voltage sensor, the drive control unit of each transfer switch 43, 44, 47, 48 are all connected with the intelligent phase splitter control unit (not shown in the figure).

[0070] The working process of the step phase-shifting power supply 18 implementation case one of the present invention is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com