A drying control method of a multi-cylinder washing and drying machine and a multi-cylinder washing and drying machine

A drying control, all-in-one technology, which is applied to the control device of washing machines, other washing machines, washing machines with containers, etc., can solve the problems of long time, reduced use experience, high power consumption, etc. Applicable to electricity environment, the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

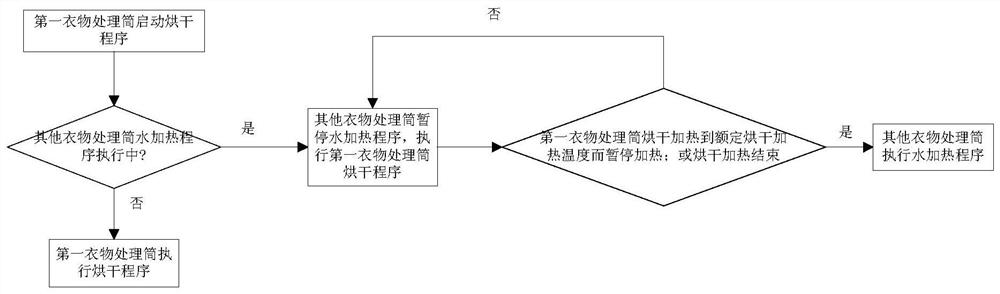

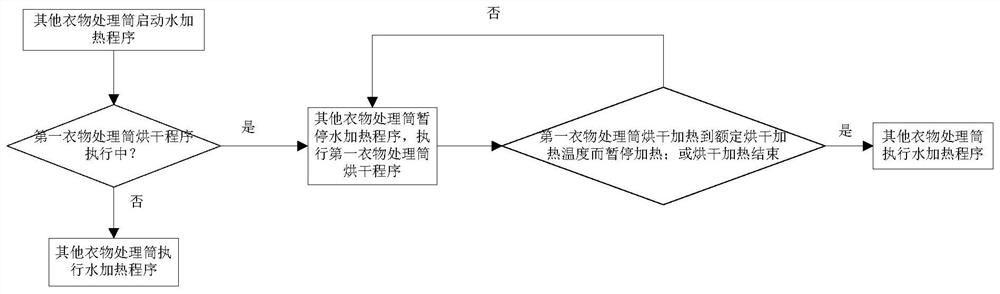

[0035] Such as Figure 1 to Figure 2 The illustrated invention discloses a drying control method for a multi-tub washer-dryer.

[0036] This control method is applicable to an all-in-one washing and drying machine including multiple laundry processing cylinders. The laundry processing cylinder can perform various laundry processing tasks such as washing, rinsing, and dehydration. At least one of the laundry treatment cylinders is capable of performing a drying program for drying the laundry, and the laundry treatment cylinder is the first laundry treatment cylinder.

[0037] The first laundry processing cylinder utilizes electric heating to evaporate and dry the moisture in the washed laundry immediately, and higher electric power is required in the drying and heating stage. At the same time, in order to improve the cleaning rate of clothes, most of the current multi-tubular washing machines are equipped with water heating equipment for the washing tub, and use electric heat...

Embodiment 2

[0048] This embodiment is a supplement to the process of executing the drying program in Embodiment 1. In this embodiment, since the temperature during the drying process cannot be kept at a high temperature for a long time, the first laundry processing cylinder implements the drying of the laundry by heating in stages. That is to say, when the first clothes processing cylinder is dried and heated to the rated drying heating temperature, the heating of the first clothes processing cylinder will be suspended, and when it is lower than the minimum temperature of the rated drying clothes, the first clothes will be started again. The heating device of the processing drum increases the temperature of the first laundry processing drum. Therefore, the drying program of the first clothes processing cylinder is a staged heating process, and the drying and heating device of the first clothes processing cylinder does not need to input electric power during many periods of the whole dryin...

Embodiment 3

[0051] This embodiment is a supplement to the above-mentioned embodiment, and the difference from Embodiment 2 is that in this embodiment, when the first laundry processing drum starts the drying program before the other laundry processing drums start the water heating program, other clothes The processing cylinder waits for the first laundry processing cylinder to complete the entire drying process and then starts the water heating process. In this embodiment, the drying program is not realized by staged heating as in Example 2, but is continuously heated, that is to say, there is no first laundry treatment during the entire drying process. The drying and heating device of the cylinder does not need an electric heating stage, so there is no technical solution for alternately heating the drying and heating device of the first laundry treatment cylinder and the water heating devices of other laundry treatment cylinders.

[0052] In this embodiment, the control method of startin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com