Barrel-shaped foundation capable of weakening soil plug phenomenon

A barrel-shaped foundation and phenomenon technology, which is applied to the barrel-shaped foundation field of marine engineering, can solve problems such as increasing construction difficulty and increasing construction costs, and achieves the effects of low price, reduction of hydraulic gradient, and elimination of soil plug phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

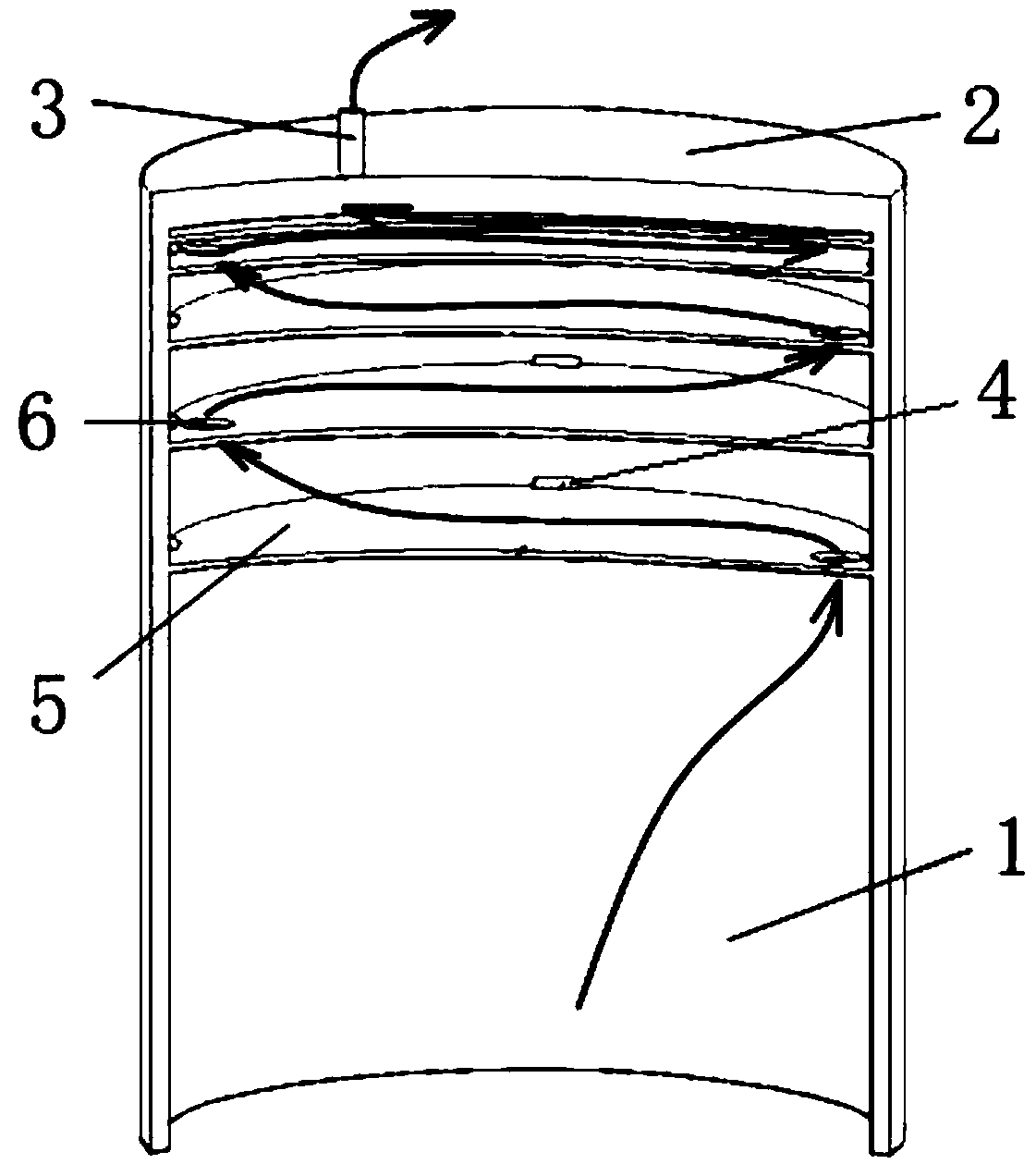

[0031] See the accompanying drawings (the arrows in the figure indicate the flow path of water and air):

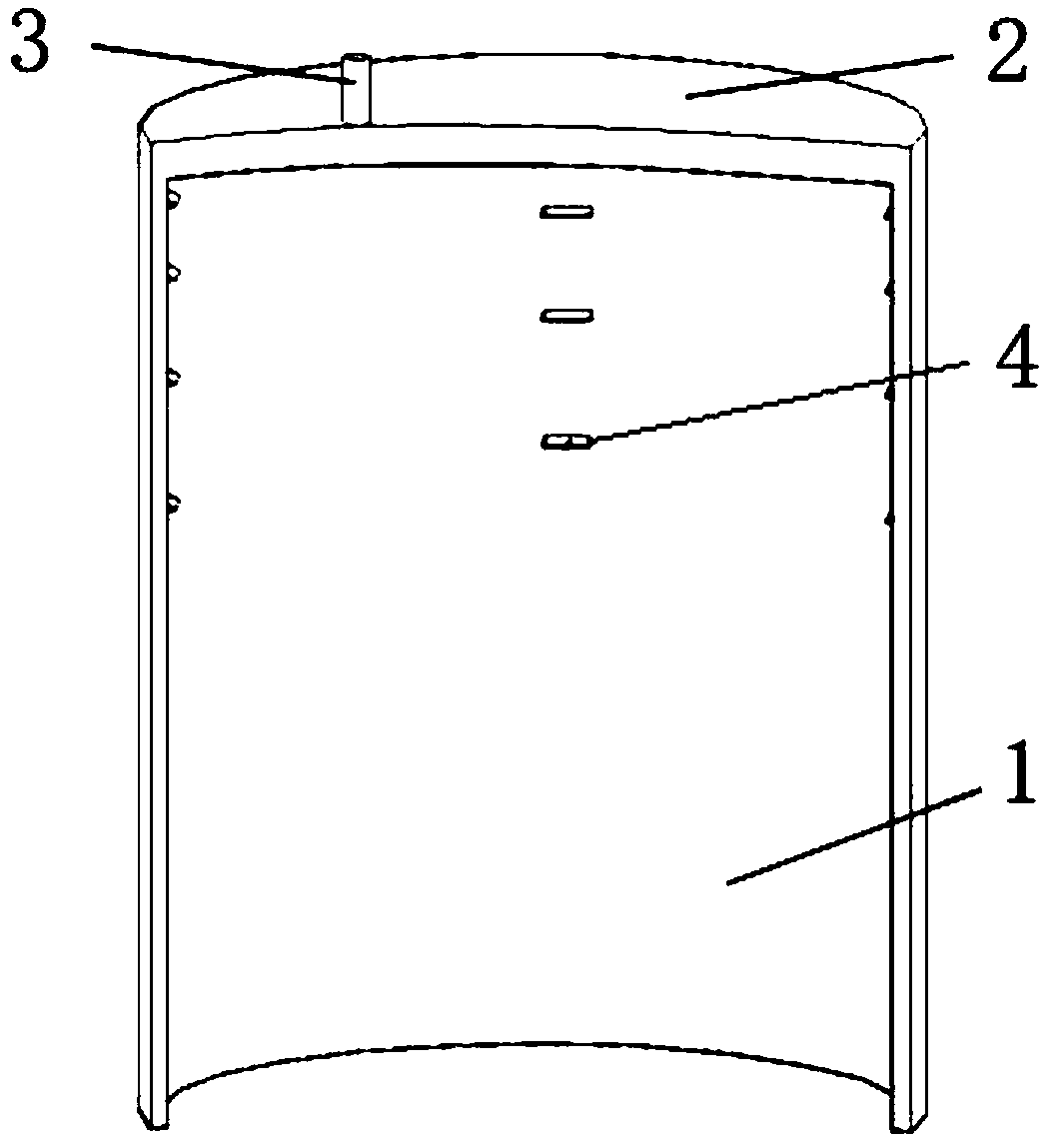

[0032] A bucket-shaped foundation capable of reducing soil plugging, including a cylinder 1, a top plate 2, and a partition 5. The top of the cylinder 1 is sealed and connected with a top plate 2 to form an inverted barrel shape, and the top plate 2 is provided with a water inlet valve 3;

[0033] The inner wall of the cylinder 1 is provided with a plurality of partitions 5 distributed at intervals, and the partitions 5 are in sealing contact with the inner wall of the cylinder 1;

[0034] All partitions 5 are set within 1 / 2 of the cylinder height from the top of the barrel; the spacing between the partitions 5 is not equidistant, and the spacing between adjacent partitions 5 gradually decreases from bottom to top;

[0035] The partitions 5 are made of brittle materials, and each partition 5 is provided with an eccentric reserved hole 6;

[0036] After each dividing plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com