Double-row self-aligning roller bearing with sealed nylon cages

A technology of self-aligning roller bearings and cages, applied to rolling contact bearings, bearing elements, shafts and bearings, etc., can solve the problems of high cost, vibration and noise that cannot meet the requirements, and achieve friction reduction, good self-lubricating effect, The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

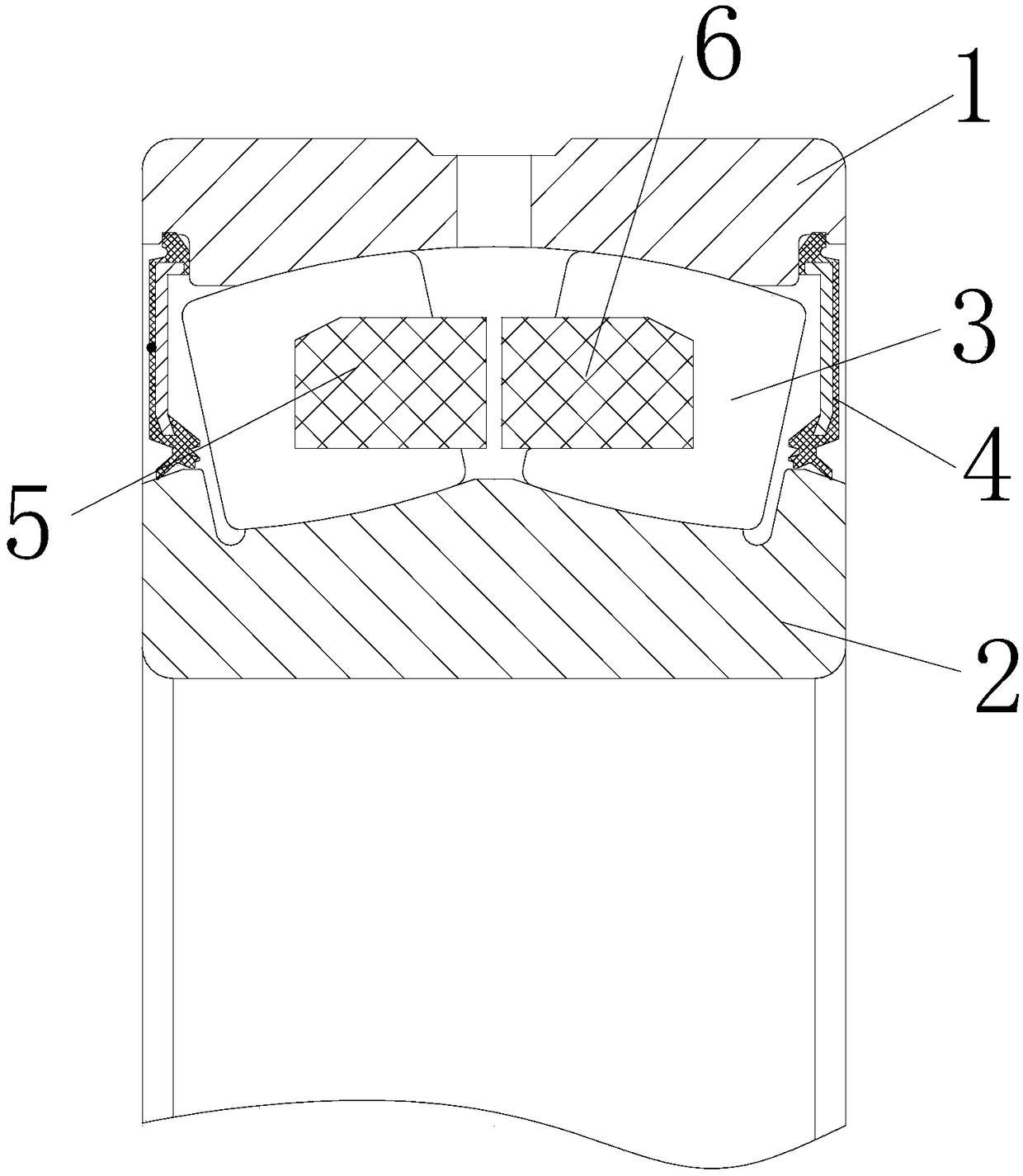

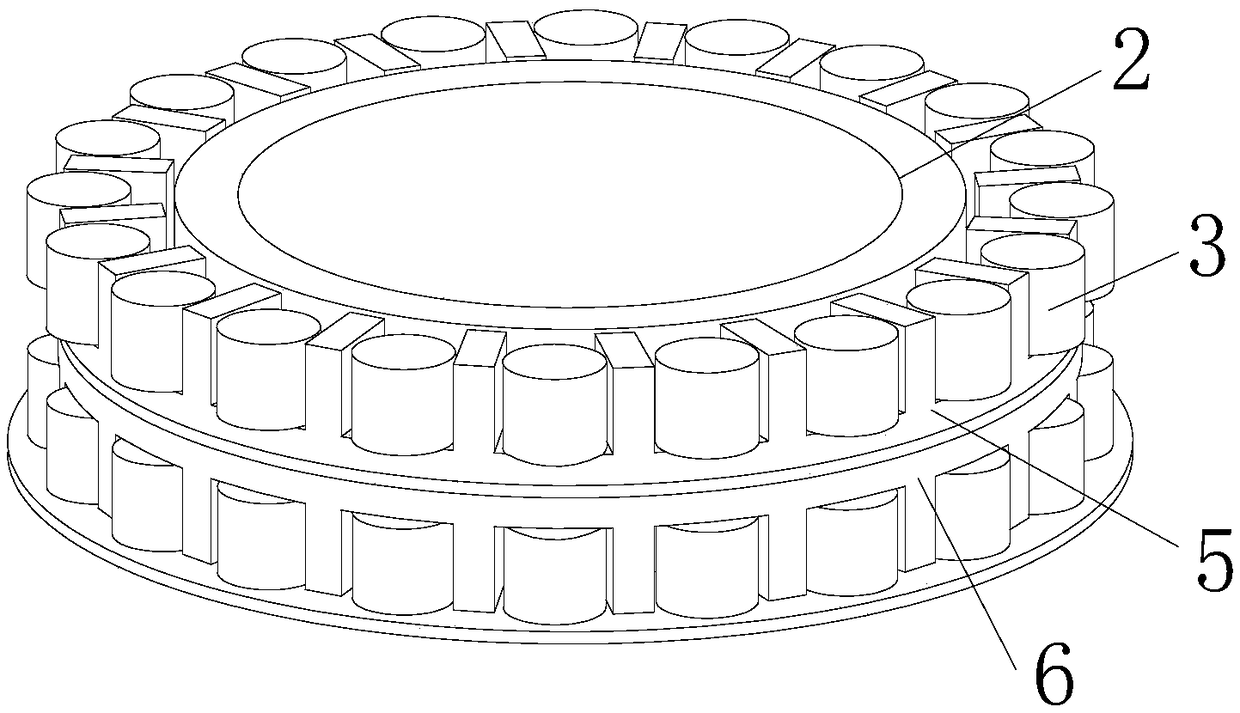

[0014] refer to Figure 1-2 , a double-row spherical roller bearing with a sealed nylon cage, including an outer ring bearing 1 and an inner ring bearing 2, the inner ring bearing 2 is a double-race inner ring bearing, and the outer ring bearing 1 is clamped outside the inner ring bearing 2 , the outer ring bearing 1 and the inner ring bearing 2 are finished by ultra-fine grinding, and the outer ring bearing 1 and the inner ring bearing 2 are sleeved outside the inner ring bearing 2. There are a first cage 5 and a second cage 6, the second Both the first cage 5 and the second cage 6 are nylon cages of the same structure, and both are made of PA46-30GF material, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com