Flow path switching valve

A flow path switching and flow path technology, applied to valve devices, multi-way valves, cocks including cut-off devices, etc., can solve problems such as pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

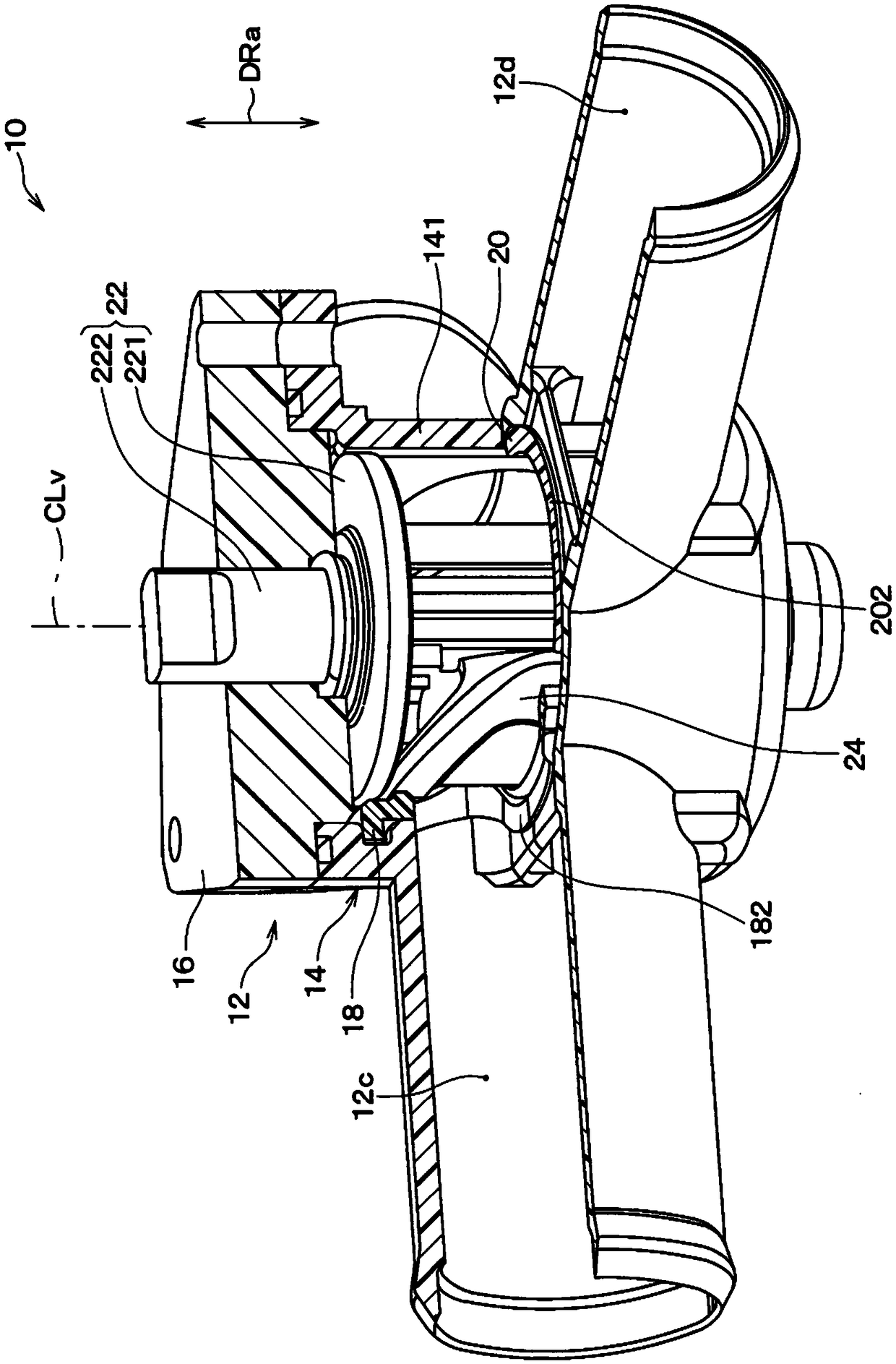

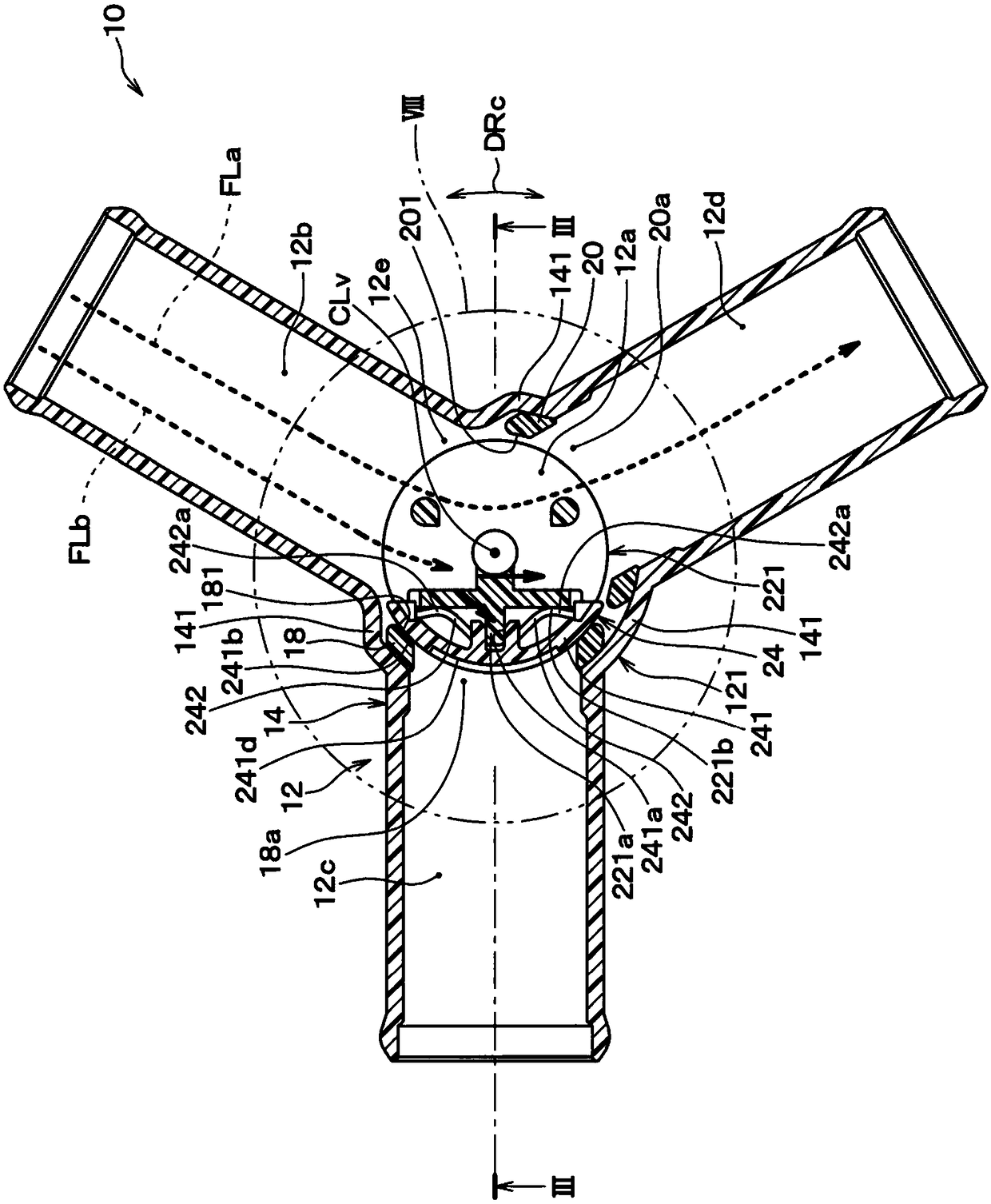

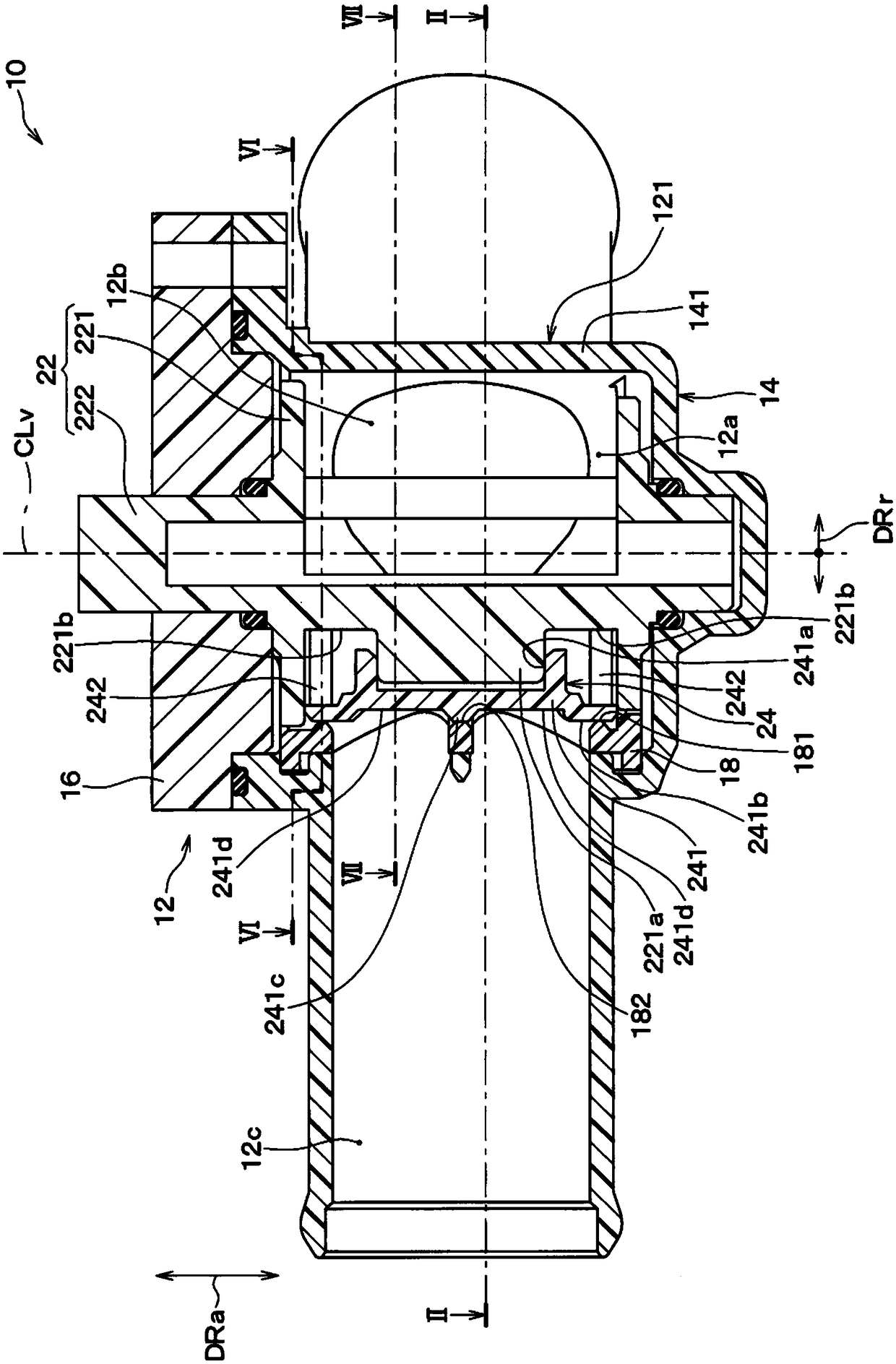

[0031] Such as figure 1 and figure 2 As shown, the channel switching valve 10 is a rotary valve that switches the channel through which fluid flows. Specifically, the channel switching valve 10 is a rotary three-way valve. The fluid flowing through the channel switching valve 10 , that is, the circulating fluid is specifically a liquid. The channel switching valve 10 includes a valve main body 12 , a controller member 22 , and a packing member 24 .

[0032] The valve main body portion 12 includes a valve body member 14 , a cover member 16 and two sealing members 18 , 20 . For example, the valve body member 14, the cover member 16, and the two sealing members 18 and 20 are all made of resin.

[0033] Such as figure 2 and image 3 As shown, a valve chamber 12 a , an inflow hole 12 b , a first outflow hole 12 c , and a second outflow hole 12 d are formed in the valve main body 12 . Specifically, the valve chamber 12 a is mainly formed in the valve body member 14 in the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com