Electromagnet device and electromagnetic relay

An electromagnetic relay, electromagnet technology, applied in the direction of electromagnetic relay, electromagnetic relay detailed information, relay, etc., can solve the problem of rotation angle limitation, cannot increase, cannot increase the distance between the opening and closing contacts of electromagnetic relay, etc. The effect of increasing the rotation radius and the large linear driving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

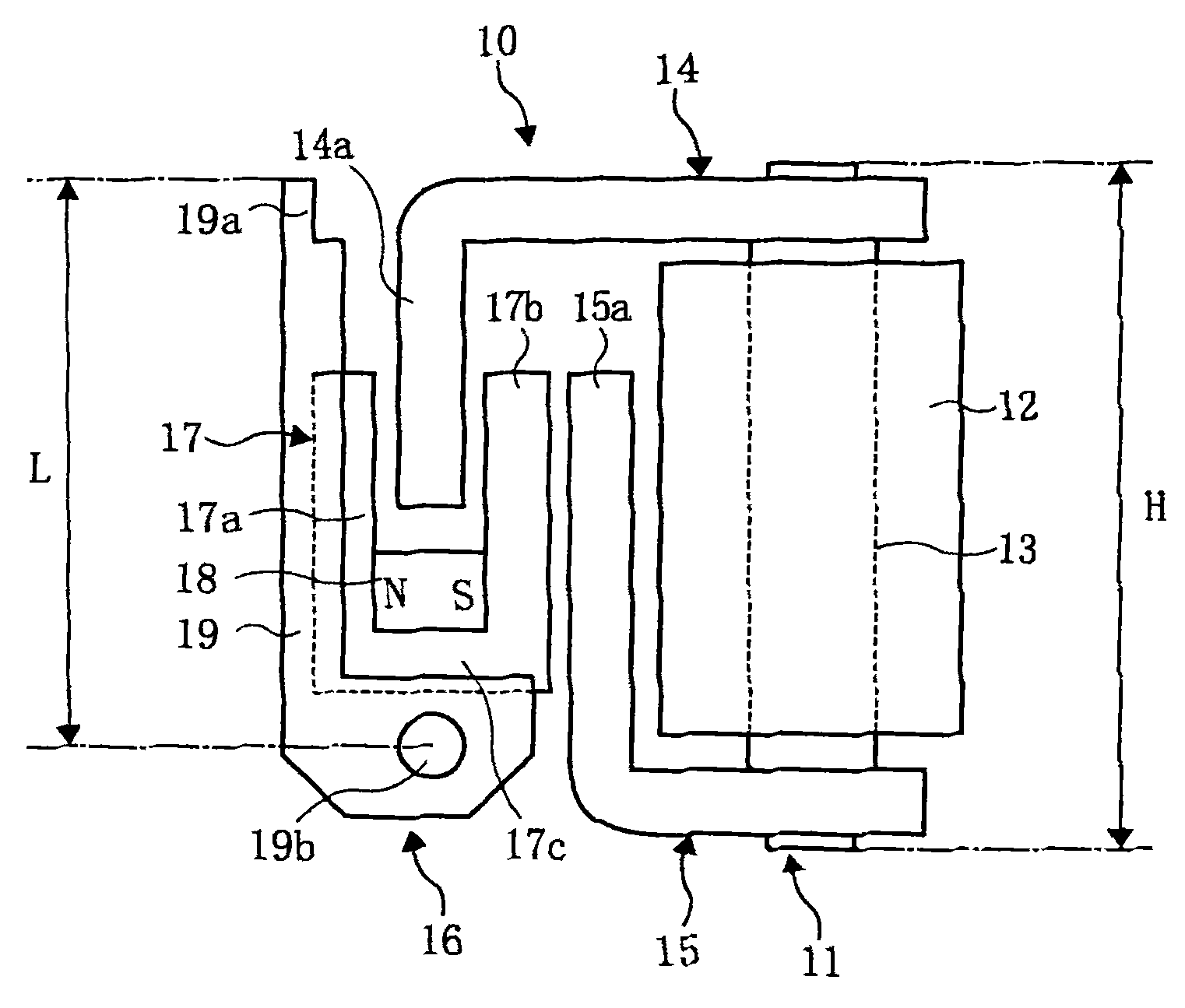

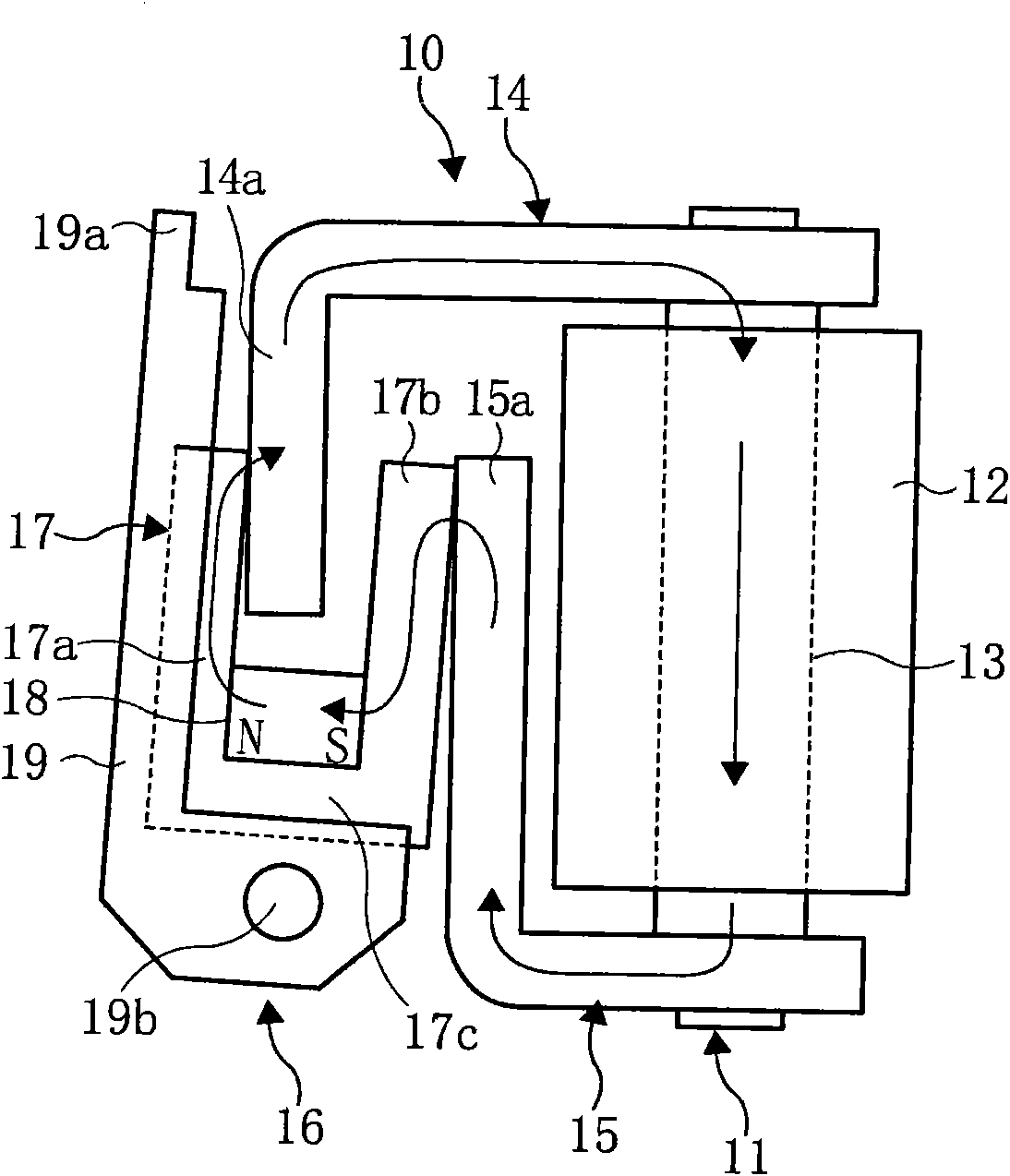

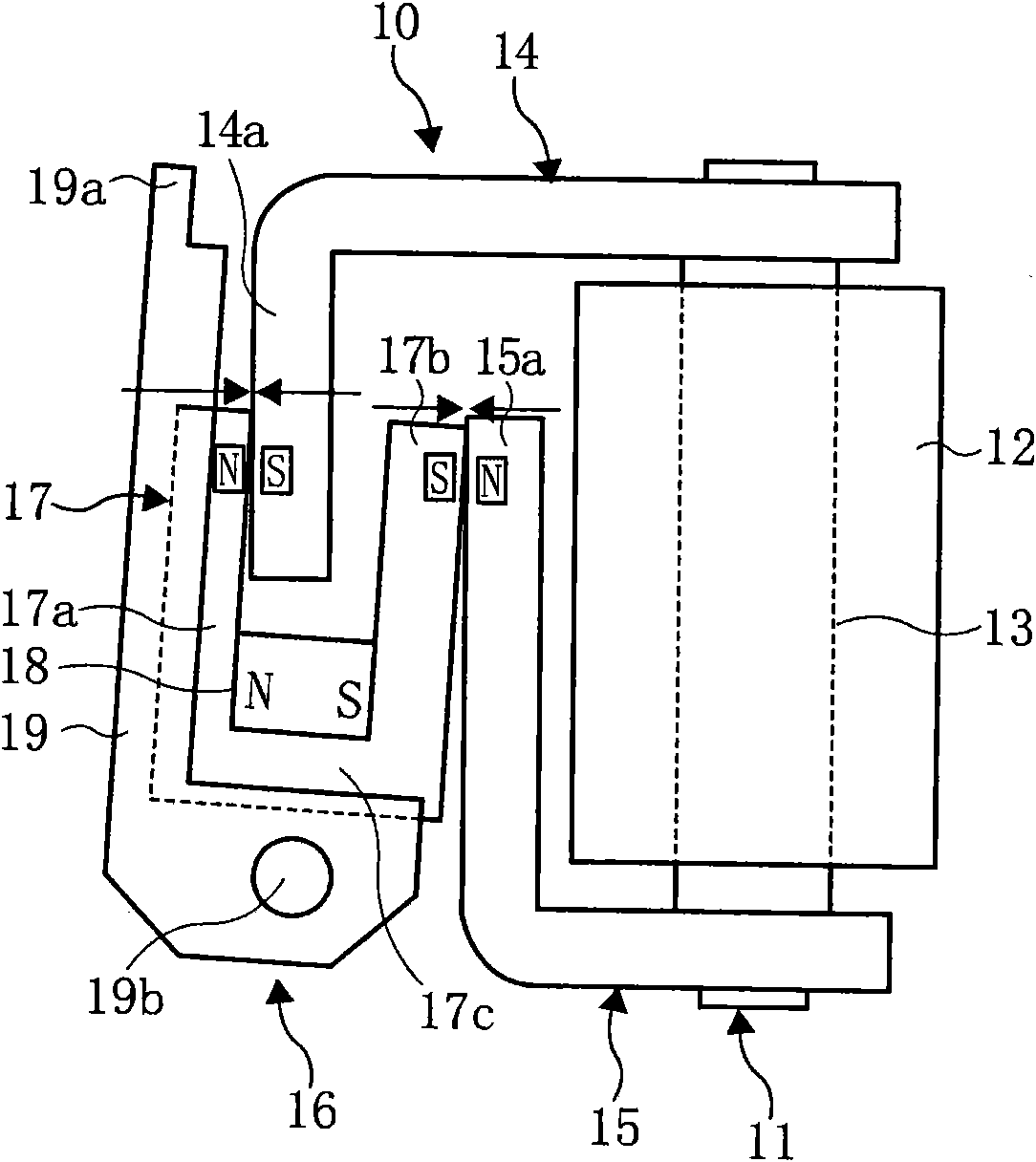

[0061] figure 1 It is a front view showing the configuration of an embodiment of the electromagnet device of the present invention.

[0062] In this figure, reference numeral 10 is an electromagnet device. The electromagnet unit 11 of the electromagnet device 10 is constituted by mechanically and magnetically coupling yokes 14 and 15 to both ends of a core 13 around which an electromagnetic coil 12 is wound. Front end portions 14 a and 15 a of the yokes 14 and 15 , which are bent in the vertical direction, are arranged in parallel at a predetermined distance from each other, and partially overlap each other.

[0063] The movable iron core part 16 includes a movable iron core 17 formed in a U-shape by two iron core legs 17a, 17b arranged in parallel at a certain interval and a connecting leg 17c connecting the lower ends of the iron core legs. The permanent magnet 18 is in contact with the connection leg 17c, and is installed between the parallel core legs 17a and 17b of the...

Embodiment 2

[0076] Figure 8 and Figure 9 It shows an example of the electromagnetic relay using the electromagnet device of the present invention.

[0077] In the figure, reference numeral 10 is an electromagnet device having the same configuration as the above-mentioned electromagnet device, and reference numeral 20 is an opening and closing contact mechanism of an electromagnetic relay.

[0078] The opening and closing contact mechanism 20 includes two groups of normally open switches made of a spring material, the front end of which is composed of a fixed contact piece 22a with a fixed contact 21a and a movable contact piece 24a with a movable contact 23a. Contact mechanism (so-called a contact mechanism). And, it includes a group of normally closed opening and closing contact mechanisms ( The so-called b contact mechanism).

[0079] The base ends of the fixed contact pieces 22a, 22b and the movable contact pieces 24a, 24b are respectively embedded in an insulating base 27 made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com