Coffee maker and control method and device thereof and readable storage medium

A control method and technology of a control device are applied in beverage preparation devices, household appliances, applications, etc., and can solve the problems of long waiting time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

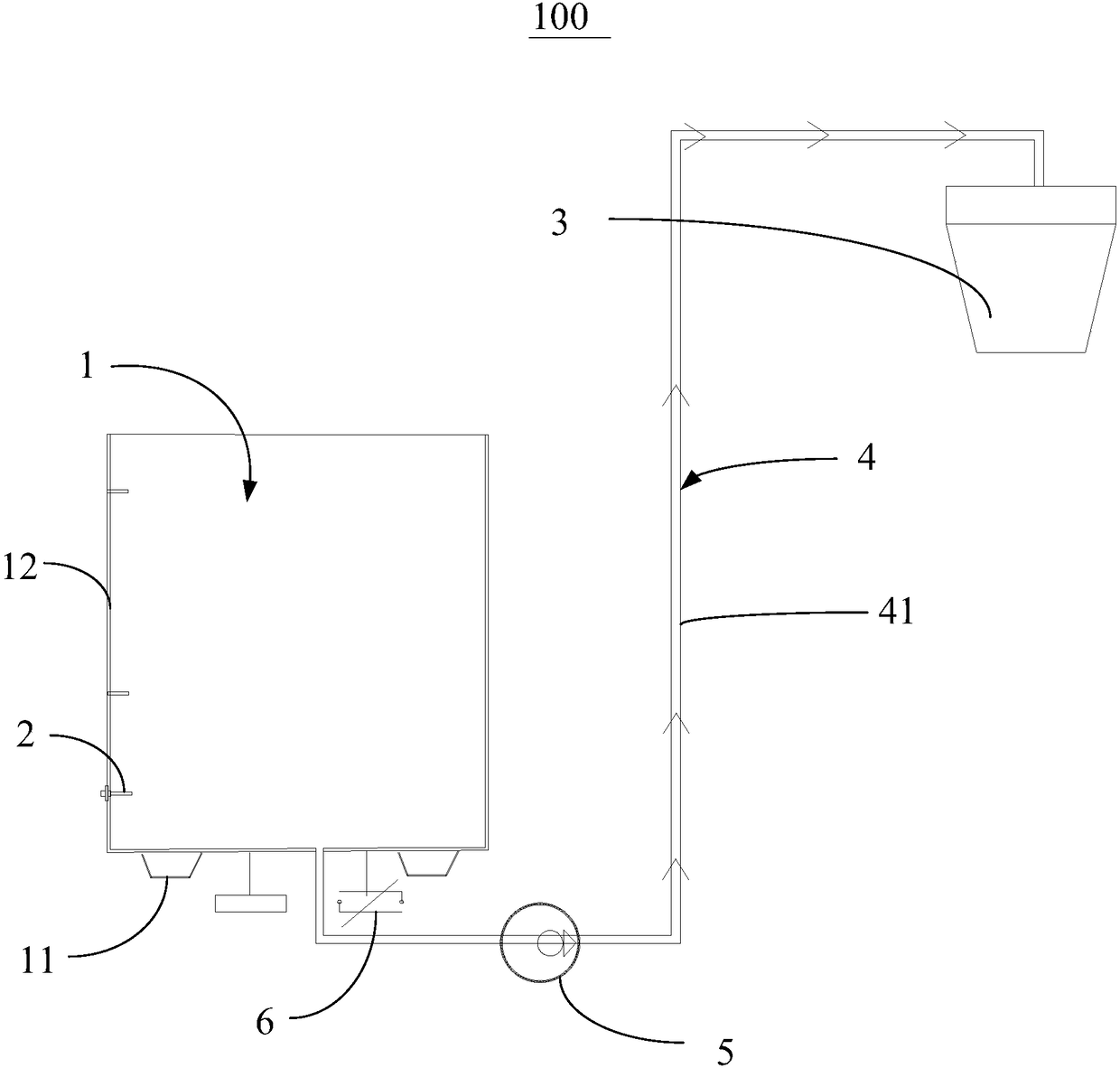

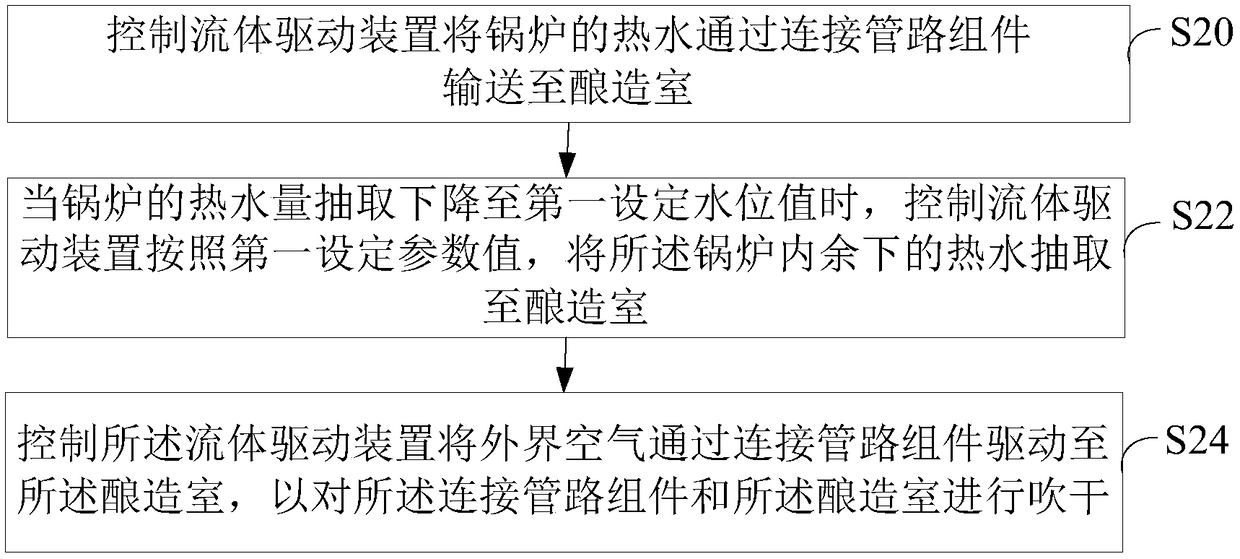

[0093] Implementation mode 1, please refer to figure 1 , the connecting pipeline assembly 4 is connected between the water outlet of the boiler 1 and the water inlet of the brewing chamber 3; the fluid driving device 5 is a driving pump arranged on the connecting pipeline assembly 4, The driving pump is controlled by the controller to deliver the hot water in the boiler 1 to the brewing chamber 3, and deliver the outside air to the brewing chamber 3 through the boiler 1 and the connecting pipeline assembly 4 Describe the brewing chamber 3.

[0094] When the preparations for brewing coffee are completed (including the heating of the hot water in the boiler 1, and the coffee powder in the brewing chamber 3 is ready), the controller controls the drive pump to drive the hot water in the boiler 1 through the connection The pipeline assembly 4 is extracted to the brewing chamber 3;

[0095] When the brewing of coffee is completed, the controller drives the pump to work, drives the...

Embodiment approach 2

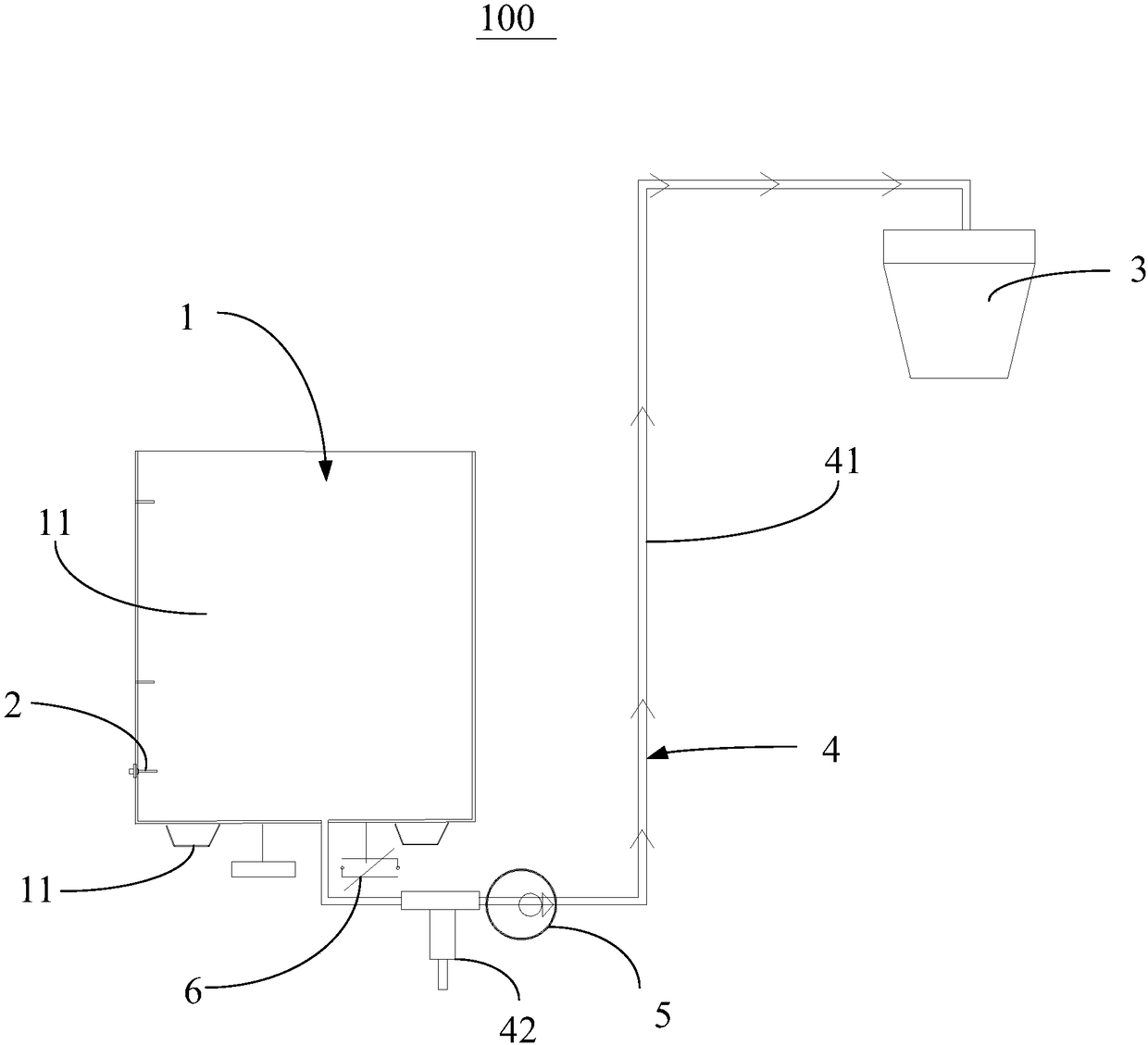

[0097] Implementation mode 2, please refer to figure 2 , the connecting pipeline assembly 4 includes:

[0098] a main pipeline 41 connected between the water outlet of the boiler 1 and the water inlet of the brewing chamber 3; and,

[0099] Three-way valve 42, two ports of the three-way valve 42 are connected in the main pipeline 41, and the other port is connected with the outside atmosphere, and the three-way valve 42 is controlled by the controller to switch respectively Conducting the main pipeline 41 and communicating the external atmosphere with the brewing chamber 3;

[0100] The fluid driving device 5 is a driving pump arranged on the connecting pipeline assembly 4, the driving pump is arranged between the three-way valve 42 and the brewing chamber 3, and the driving pump is controlled by the The controller is used to deliver the hot water in the boiler 1 to the brewing chamber 3 or the outside air to the brewing chamber 3 .

[0101] When the preparations for brewi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com