Efficient shoe material finishing agent and preparation method thereof

A technology for finishing agents and shoe materials, applied in chemical instruments and methods, chemical/physical processes, mixers with rotating stirring devices, etc., can solve problems such as low mixing efficiency, inconvenient quantitative discharge, and long time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

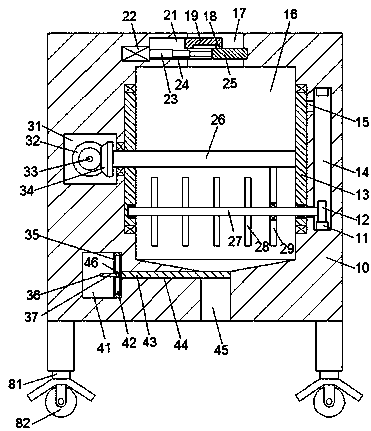

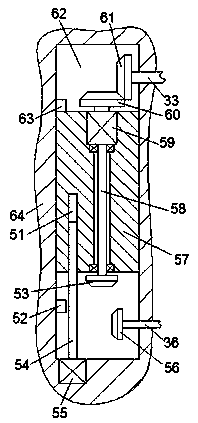

[0013] Combine below Figure 1-2 The present invention will be described in detail.

[0014] refer to Figure 1-2 , according to an embodiment of the present invention, a high-efficiency shoe material finishing agent and its preparation method include an outer shell 10, a stirring chamber 16 is arranged inside the outer shell 10, and the left and right side walls of the stirring chamber 16 are rotated and fitted A swivel seat 13 is installed, and the center between the swivel seats 13 on the left and right sides is fixed with a first rotating arm 26, and a first stirring rod 29 is fixed on the first rotating arm 26. The first stirring rod 29 is rotated and fitted with a stirring shaft 27, and the outer surface of the stirring shaft 27 is fixedly provided with multiple groups of second stirring rods 28, and the stirring shaft 27 is respectively rotated and matched with the said swivel seat 13 on the left and right sides. connected, the outer casing 10 on the right side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com