Hydraulic shear

A technology of hydraulic shears and hydraulic cylinders, applied in the field of hydraulic shears, can solve problems such as cutter body damage and reduced efficiency, and achieve the effects of eliminating guide rail gaps, improving shearing quality, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

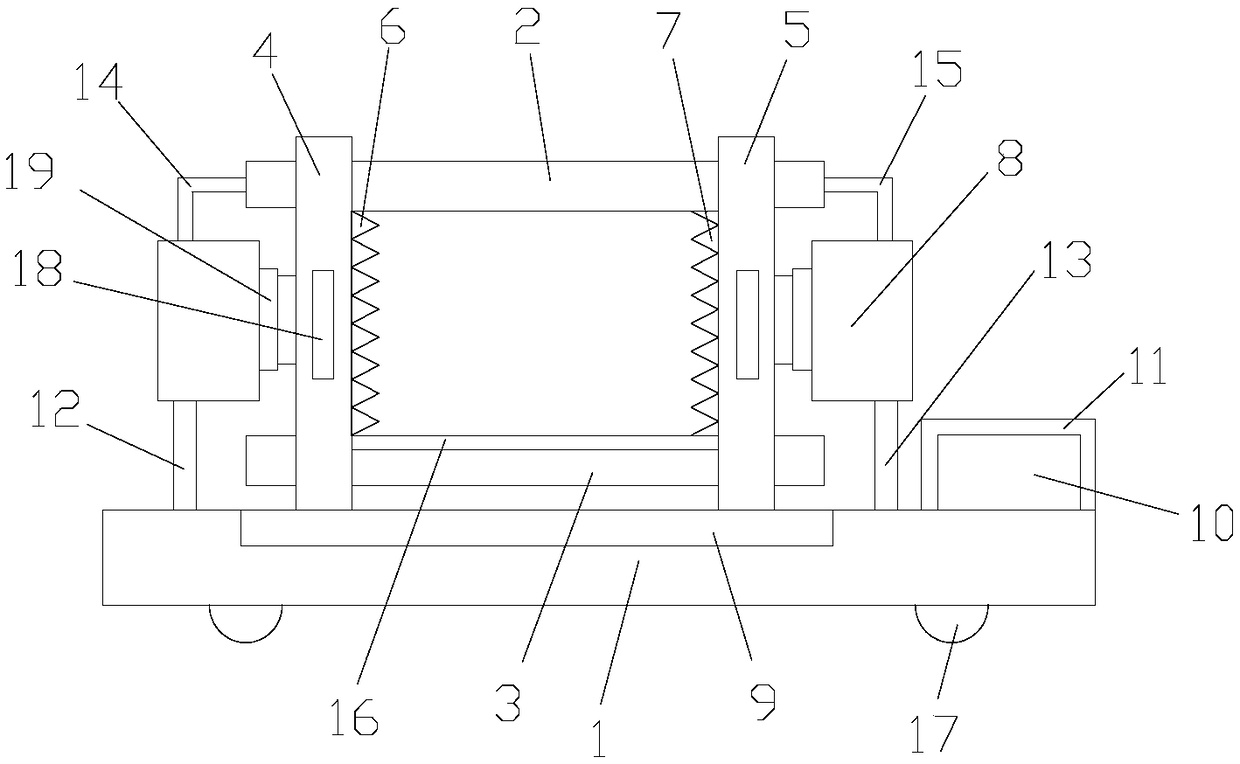

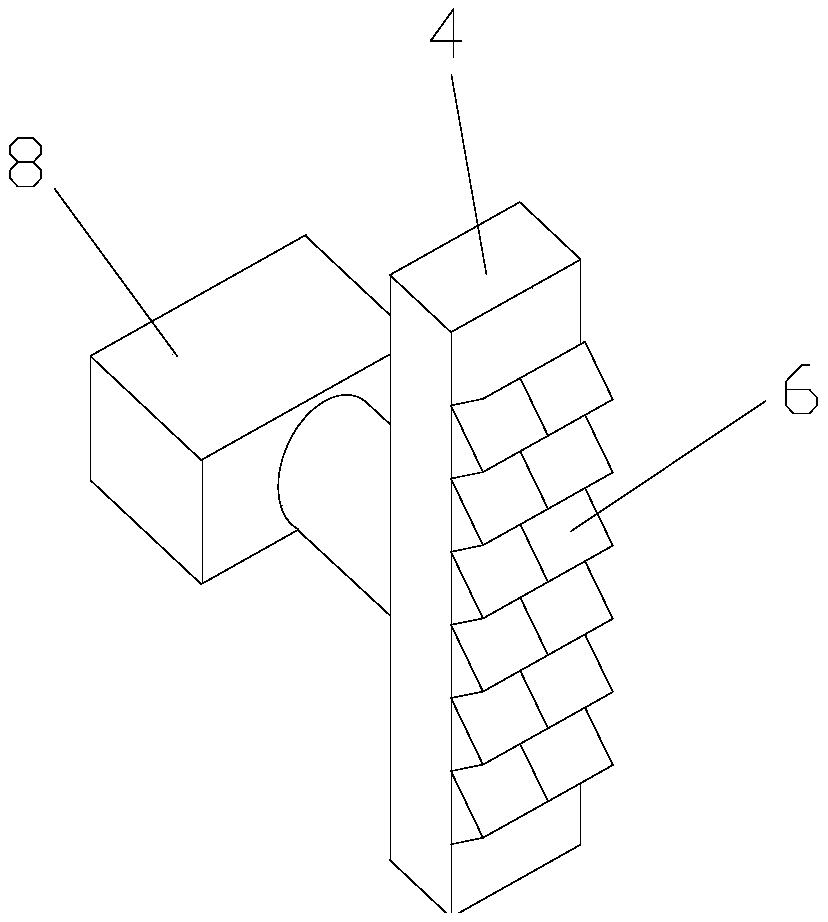

[0024] like figure 1 As shown, a hydraulic shear comprises a base 1 and a hydraulic shear frame positioned above the base, and the hydraulic shear frame includes a first guide post 2, a second guide post 3, a first shear tool holder 4 and a second guide post 4. Two shear blade holders 5, one end of the first guide column 2 and the second guide column 3 all pass through the first shear blade holder 4, and the other ends of the first guide column 2 and the second guide column 3 all pass through The second shearing blade frame 5, the first shearing blade frame 4 and the second shearing blade frame 5 are symmetrically distributed, and the first shearing blade frame 4 and the second shearing blade frame 5 are all connected with the first shearing blade frame 5. A guide column 2 is movably connected with the second guide column 3, the first shearing tool holder 4 is provided with a first cutter body 6, and the second shearing tool holder 5 is provided with a The second cutter body ...

Embodiment 2

[0027] like Figure 1-2 As shown, a hydraulic shear comprises a base 1 and a hydraulic shear frame positioned above the base, and the hydraulic shear frame includes a first guide post 2, a second guide post 3, a first shear tool holder 4 and a second guide post 4. Two shear blade holders 5, one end of the first guide column 2 and the second guide column 3 all pass through the first shear blade holder 4, and the other ends of the first guide column 2 and the second guide column 3 all pass through The second shearing blade frame 5, the first shearing blade frame 4 and the second shearing blade frame 5 are symmetrically distributed, and the first shearing blade frame 4 and the second shearing blade frame 5 are all connected with the first shearing blade frame 5. A guide column 2 is movably connected with the second guide column 3, the first shearing tool holder 4 is provided with a first cutter body 6, and the second shearing tool holder 5 is provided with a The second cutter bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com