Forming machine for twisted type endless conveyer belt

A technology of endless conveyor belt and forming machine, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems that cannot be solved, such as endless conveyor belt and joint damage, and achieve the effect of novel design, improved service life, and improved yield performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

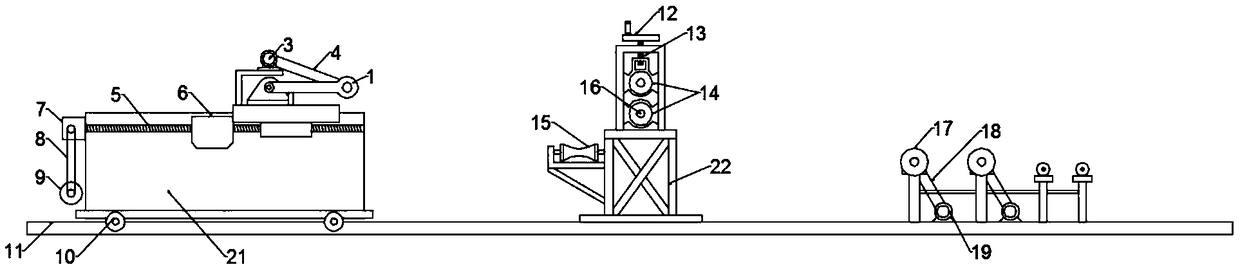

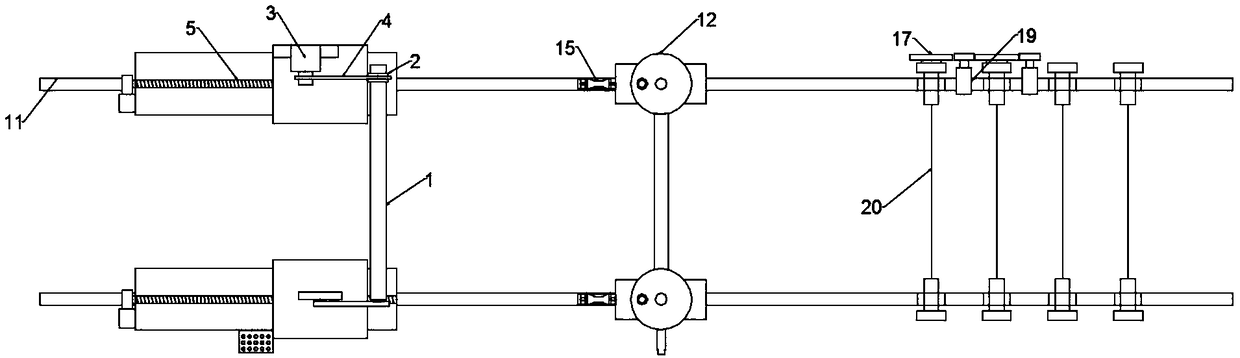

[0019] see Figure 1~2 , in an embodiment of the present invention, a winding endless conveyor belt forming machine, including a canvas guiding device, a canvas covering bonding compacting device and a rotating power device; the canvas guiding device, canvas covering bonding compacting device and The rotating power devices are arranged in the steel groove 11 sequentially from right to left, and there is a space between the canvas covering and bonding compacting device, the canvas guiding device and the rotating power device.

[0020] Specifically, the canvas guiding device includes a square steel 20 for installing a canvas roller, a friction disc 17, and a second drive mechanism 19. The square steel 20 is mounted on the support frame through bearing rotation and is connected with the friction disc 17. The disk 17 is rotationally connected with the second driving mechanism 19 through the second chain 18, and the second driving mechanism 19 drives the canvas roller on the square...

Embodiment 2

[0028] In order to maximize the scope of application of the device, this embodiment optimizes this. Specifically, the lower end of the support seat 21 is symmetrically provided with a pulley 10, and the pulley 10 slides in the channel steel 11, so that the support seat 21 and All the devices on it move as a whole to adjust the distance between the rotating power device and the canvas covering bonding compacting device.

[0029] It should be noted that the first reducer, the second reducer and the third reducer in this application are applications of the prior art, and a certain tension is given to the guided rubber canvas by adjusting the tightness of the set friction disc, so that To ensure that the rubber canvas is flat and not folded when it passes through the laminating roller during molding, and the positive and negative rotation of the first motor is used to realize the forward and backward movement of the forming driving roller to determine the inner circumference of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com