Insulator integration system

An integrated system and insulator technology, which is applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of low safety, poor measurement effect, simple system, etc., and achieve the effect of expanding the application range, excellent structure, and excellent system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

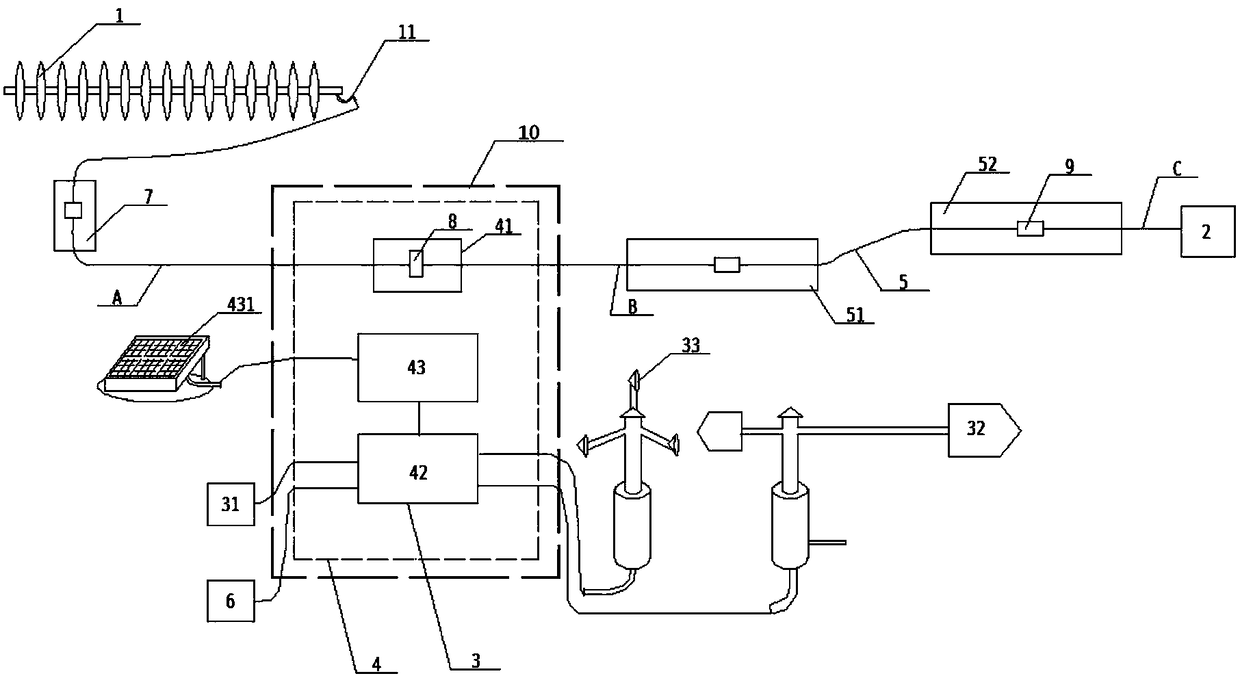

[0017] see figure 1 , an insulator integrated system, including a fiber grating composite insulator 1, a thermal insulation protection device 10 and a monitoring device, the monitoring device includes a temperature stress analysis device 2, an auxiliary measurement device 3 and a comprehensive control box 4, and in the integrated control box 4 The outer sheath is equipped with a heat insulation protection device 10;

[0018] The monitoring device includes a temperature stress analysis device 2, an auxiliary measuring device 3 and an integrated control box 4 arranged on the tower;

[0019] The inside of the integrated control box 4 is provided with a No. 1 jumper connector protection box 41, a central control box 42 and a power supply 43, and one end of the No. 1 jumper connector protection box 41 is connected with the outlet optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com