A method for dynamically control high-risk operation in a device overhaul site

A kind of operation and high-risk technology, applied in the direction of office automation, equipment, technology management, etc., can solve the problems of increased on-site operation activities, lagging progress, many departments and links, etc., and achieve the effect of facilitating safety management and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

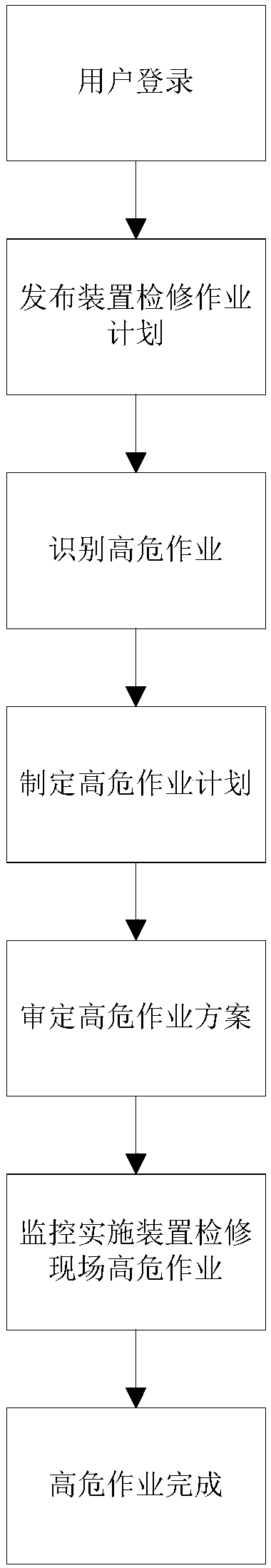

[0022] combine figure 1 , a dynamic control method for high-risk operations on site for device maintenance, including a network-based multi-terminal electronic monitoring platform, the method includes the following steps:

[0023] Step 1: User login, enterprise business or professional management department, device or territorial management department and operating unit log in to the multi-terminal electronic monitoring platform according to their different user names and passwords;

[0024] Step 2: Publish the device maintenance operation plan. The business or professional management department of the enterprise, the device or the territory management department publish the device maintenance operation plan on the multi-terminal electronic monitoring platform. The maintenance operation plan includes daily maintenance plan,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com