Door structure for dish washing machine

A dishwashing machine and door body technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problem of increasing the number of parts, assembly production process, transmission door body The complex installation structure of the dispenser and the complicated structure of the dishwasher door body have achieved the effect of good assembly quality, stable and reliable overall structure, and stable and reliable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

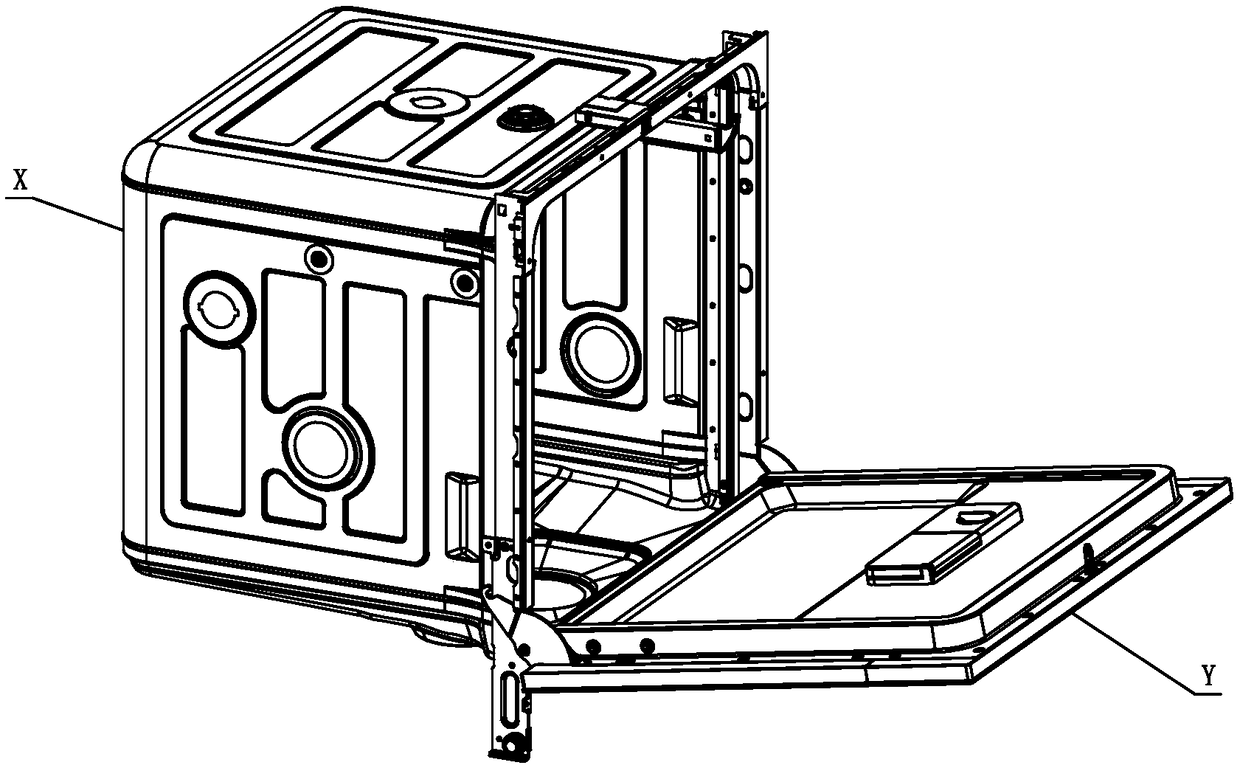

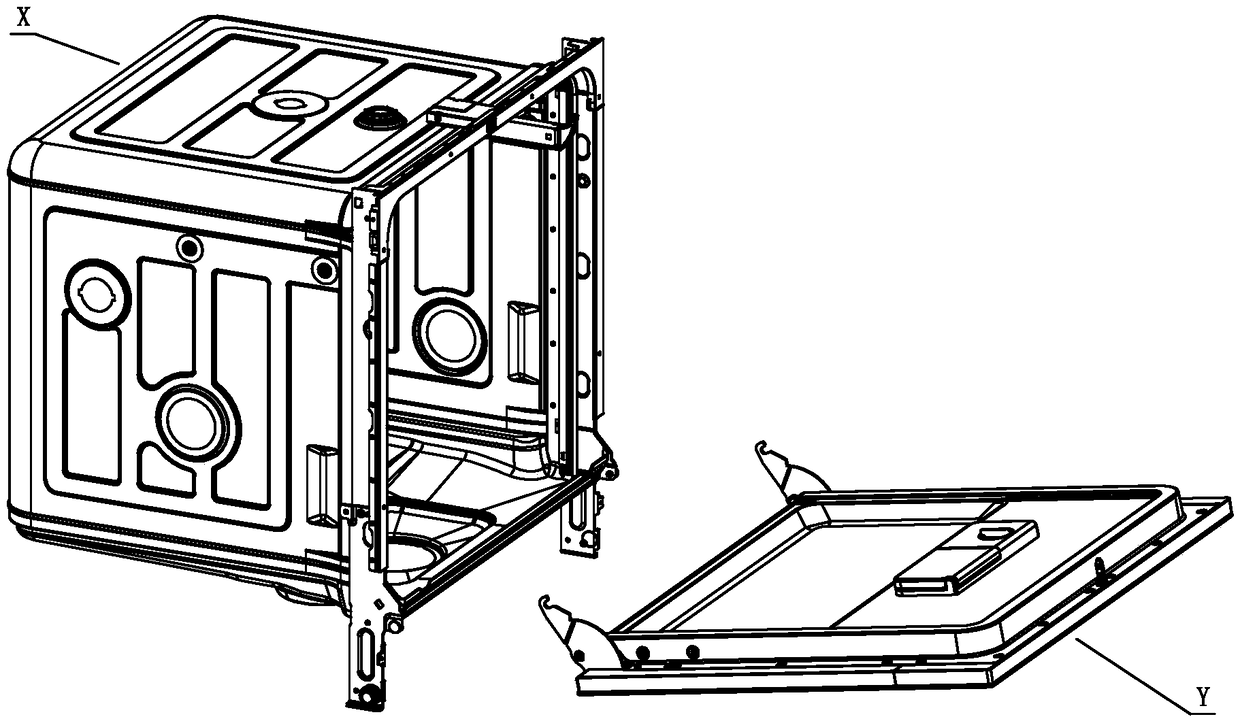

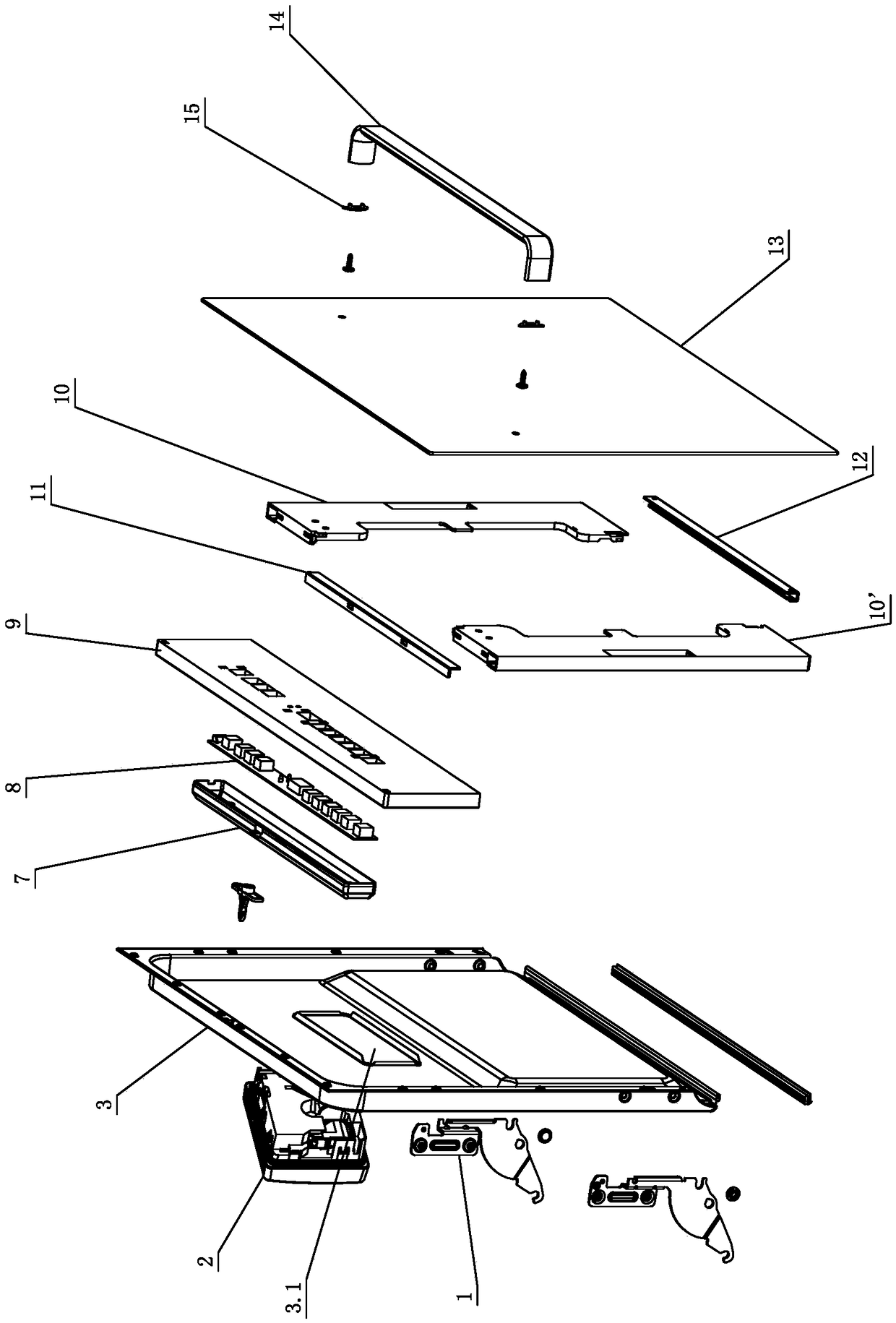

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0040] see Figure 1-Figure 24In the door structure of the dishwasher, the door body Y of the dishwasher includes an inner door 3 and a light-transmitting plate 13, and the light-transmitting plate 13 is assembled on the front side of the inner door 3, wherein the inner door 3 is connected to the washing machine through the hinge assembly 1. The bowl machine body X is hinged, and the light-transmitting plate 13 is tempered glass; in addition, the dishwasher door body Y also includes a control assembly and a door frame assembly disposed between the inner door 3 and the light-transmitting plate 13, and a door frame assembly disposed on the inner door 3. The dispenser 2, and the handle arranged on the light-transmitting plate 13; the light-transmitting plate 13 is pasted on the control assembly and the door frame assembly; the door frame assembly includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com