Exhaust and dust removal equipment and method suitable for airtight containers of gas dust explosion

A closed container, dust explosion technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of human and environmental hazards, accident investigation lack of physical evidence analysis technical specifications, dangers, etc., to achieve comprehensive and accurate cleaning, screen Clearly visible, easy-to-step results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

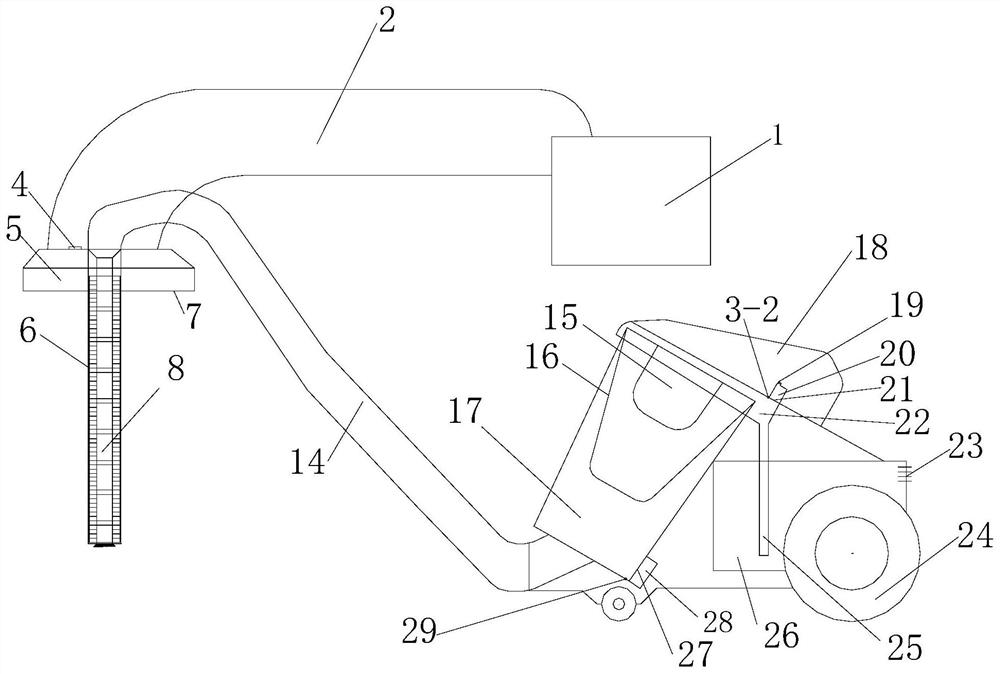

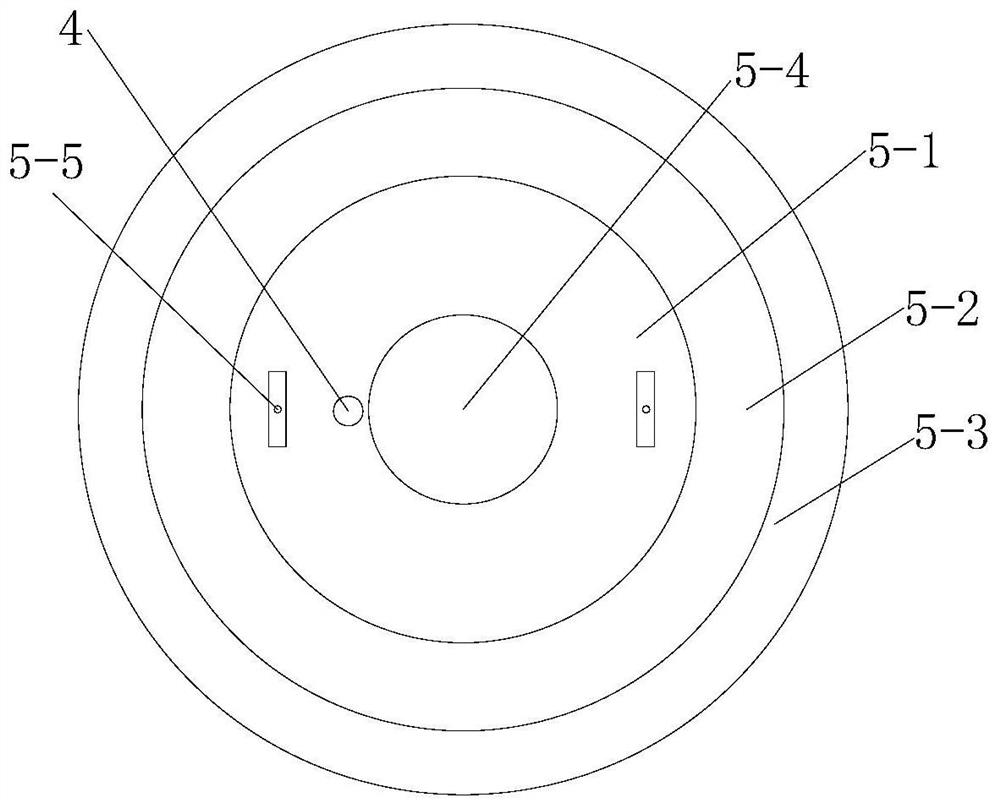

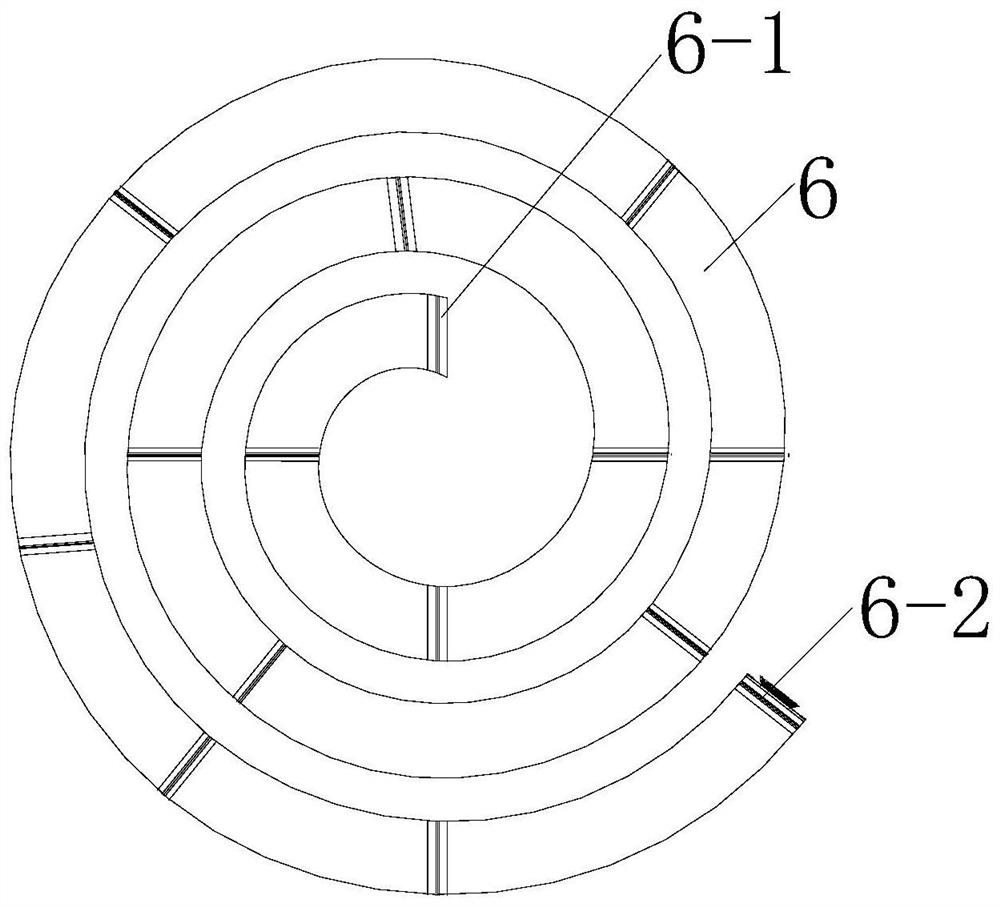

[0050] Such as Figure 1 to Figure 5 As shown, the exhaust and dust removal equipment suitable for gas dust explosion airtight containers according to the present invention includes a console 1, a sealing cover 5 that cooperates with the airtight container, and a processing mechanism that communicates with the sealing cover 5 for exhaust and dust removal. The sealing cover 5 includes a stepped cap, a No. 1 automatic opening and closing door 7 for closing or opening the stepped cap, and a serpentine mechanical arm 6 installed on the inner bottom surface of the stepped cap. The serpentine mechanical arm 6 It is a hollow structure, and the serpentine mechanical arm 6 is provided with a hose 8 equal to the length of the serpentine mechanical arm 6. The stepped cap includes a first stepped cover plate 5-1 and a second stepped one connected sequentially from top to bottom. The cover plate 5-2 and the third step cover plate 5-3, the center position of the first step cover plate 5-1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com