Electrostatic atomization device

A technology of electrostatic atomization and conductive sheets, which is applied in the direction of electrostatic spraying devices, spray discharge devices, spraying devices, etc., can solve the problems of low water delivery efficiency, achieve fast flow speed, improve electrostatic spraying efficiency, and increase condensed water flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

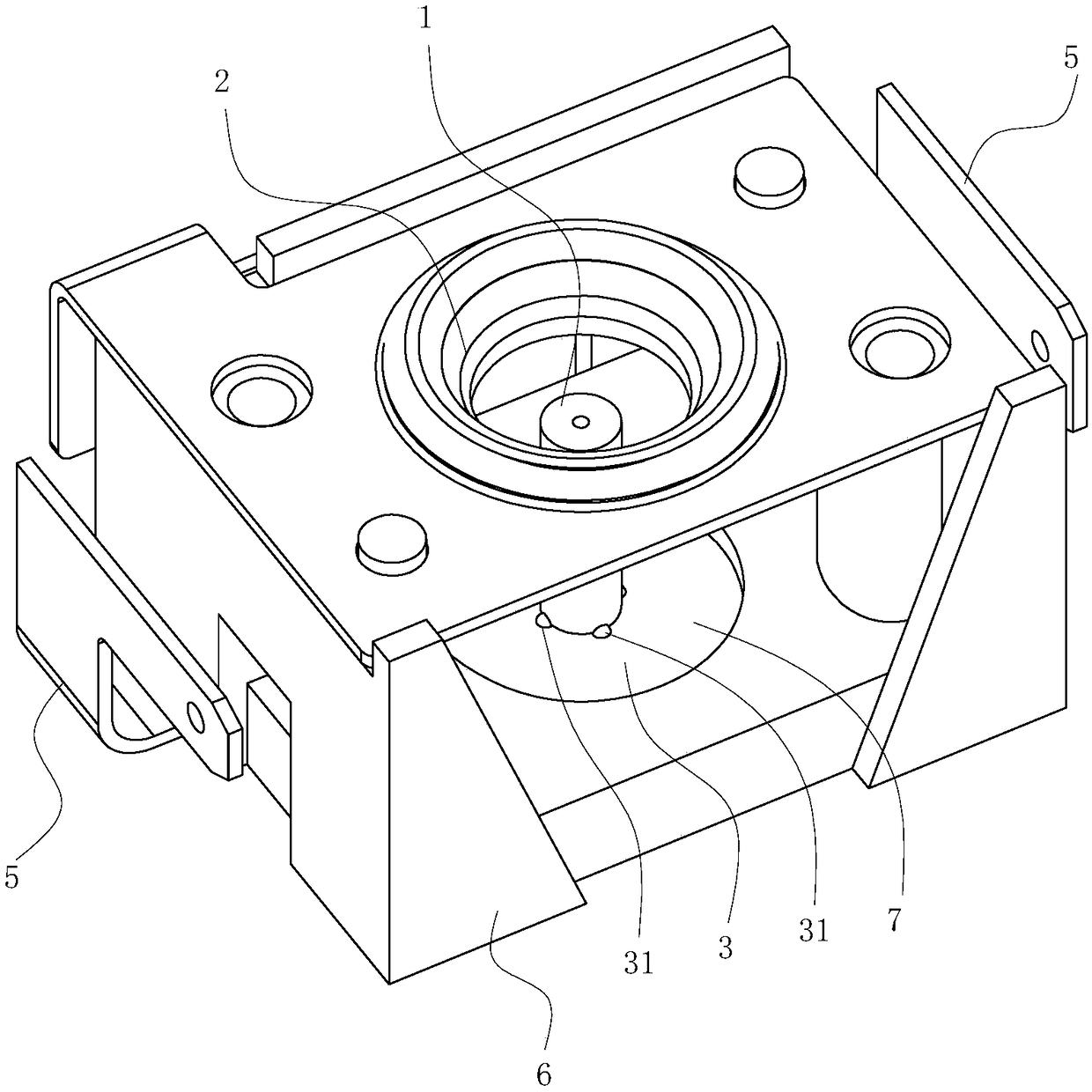

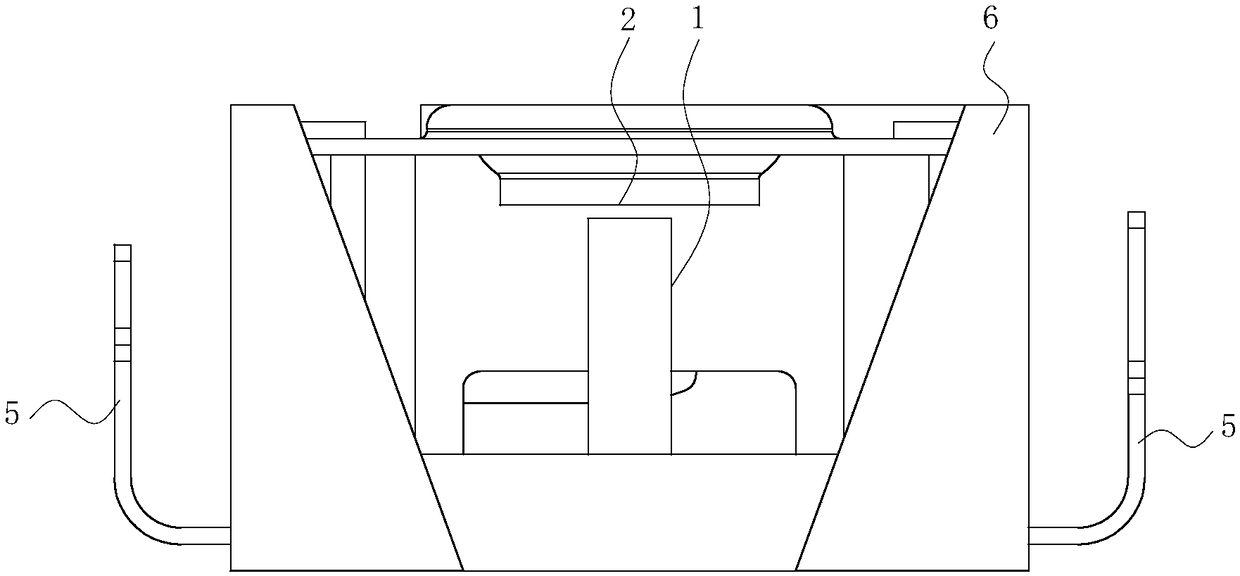

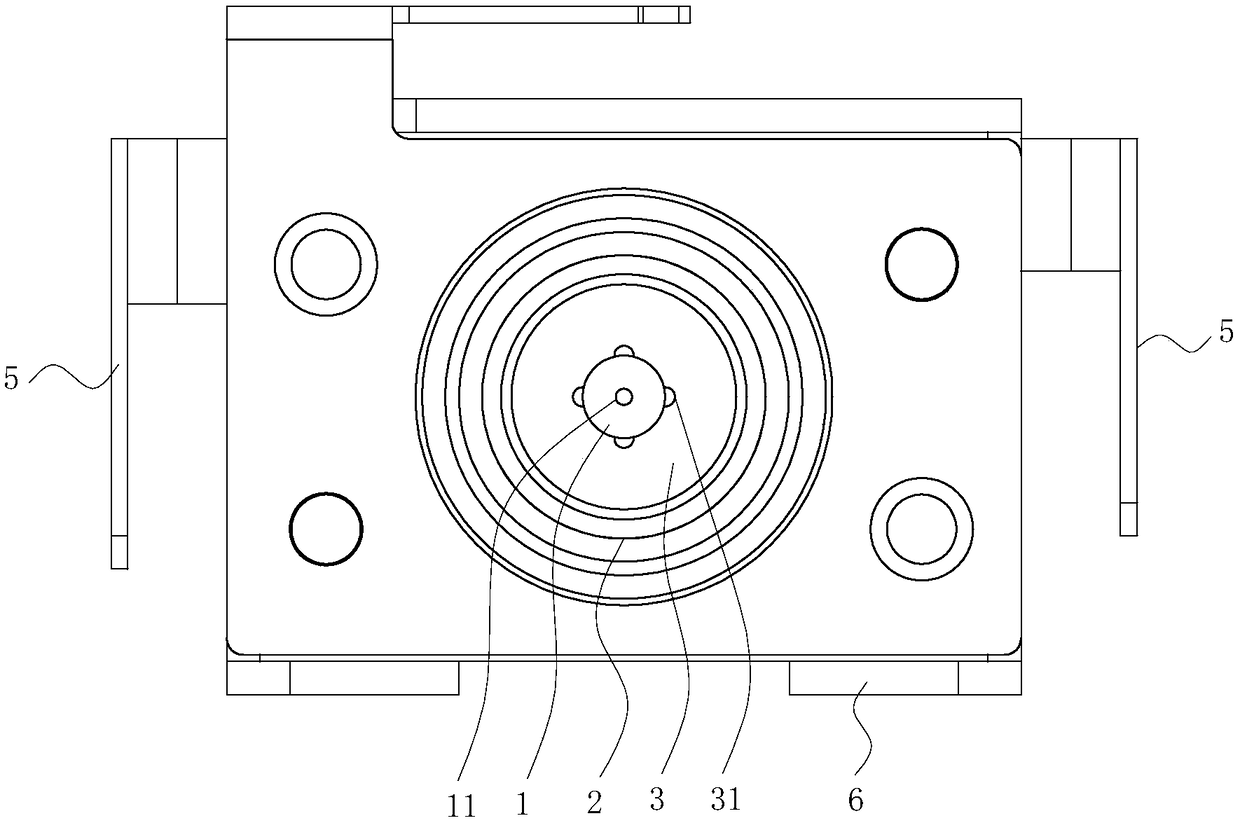

[0053] see Figure 1 to Figure 7 , an electrostatic atomization device according to Embodiment 1 of the present invention, comprising:

[0054] emitter electrode 1;

[0055] The opposite electrode 2, the opposite electrode 2 is opposite to the emitter electrode 1;

[0056] A water supply device, the water supply device provides condensed water 8 to the emitter electrode 1;

[0057] High-voltage power supply, the high-voltage power supply applies high voltage to the emitter electrode 1 and the opposite electrode 2, thereby electrostatically charging the water on the emitter electrode 1, so that the discharge end of the emitter electrode 1 ejects charged water particles;

[0058] The water supplier includes a conductive condensation pan 3 connected to the emitter electrode 1, the condensation water 8 is generated on the upper surface of the condensation pan 3, there is a gap between the condensation pan 3 and the emitter electrode 1, and the emitter electrode 1 has a through h...

Embodiment 2

[0070] The difference between the second embodiment and the first embodiment is that: the emitter electrode 1 is provided with a through capillary groove.

[0071] see Figure 8 to Figure 10 The outer surface of the emitter electrode 1 is provided with a through capillary groove 12, and the condensed water 8 flows from the condensation pan 3 into the capillary groove 12 through capillary action. There are multiple and identical capillary grooves 12 on each emitter electrode 1 , and the plurality of capillary grooves 12 are evenly distributed on the emitter electrode 1 . Specifically, in this embodiment, the number of capillary grooves 12 is four. The cross section of the capillary groove 12 is arc-shaped and the arc angle is greater than 180°.

[0072] Capillary grooves 12 are arranged on the outer periphery of the emitter electrode 1, and more condensed water 8 can be transported in the same time.

[0073] Other structures and effects of the second embodiment are the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com