Wheel edge transmission structure of heavy-duty vehicle

A transmission structure and heavy-duty vehicle technology, which is applied in the direction of wheels, axles, vehicle parts, etc., can solve the problems of limited application range of heavy-duty vehicles, and achieve the effect of improving versatility and improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

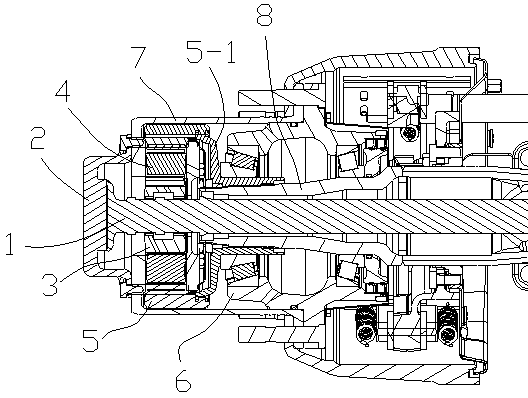

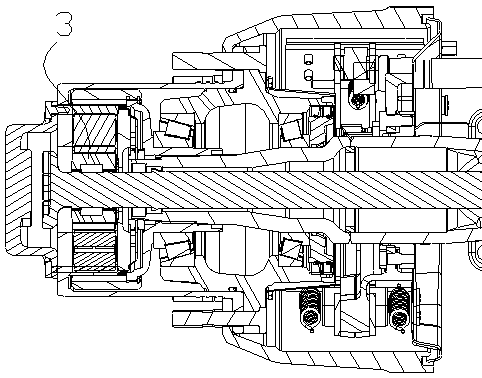

[0019] A heavy-duty vehicle wheel transmission structure, the innovation of which is: the heavy-duty vehicle wheel transmission structure includes a half shaft 1, a wheel cover 2, a sun gear 3, a planetary gear assembly 4, a fixed ring gear 5, a wheel hub 6, Wheel side cover 7 and axle sleeve 8;

[0020] The outer end of the half shaft 1 forms a transmission section 1-1, the outer end of the transmission section 1-1 is provided with a transmission disc 1-2, the outer end surface of the transmission disc 1-2 is provided with a toothed flange, and the transmission section Two spline segments 1-3 are arranged on the outer wall of the middle part of 1-1, and there is a certain distance between the two spline segments 1-3, and spline teeth are arranged on the surface of the spline segments 1-3;

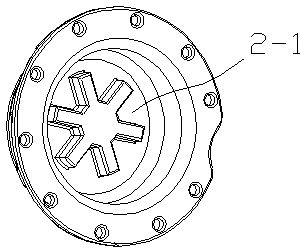

[0021] The middle part of the inner surface of the wheel edge end cover 2 is provided with a keyway 2-1 matching the tooth flange;

[0022] The inner hole of the sun gear 3 forms a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com