Gallery protecting tool

A technology for protecting tooling and corridors. It is used in transportation and packaging, ships, dry docks, etc. It can solve the problems of being vulnerable to damage and small force, and achieve the effect of avoiding damage, reducing pressure and ensuring the strength of span beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

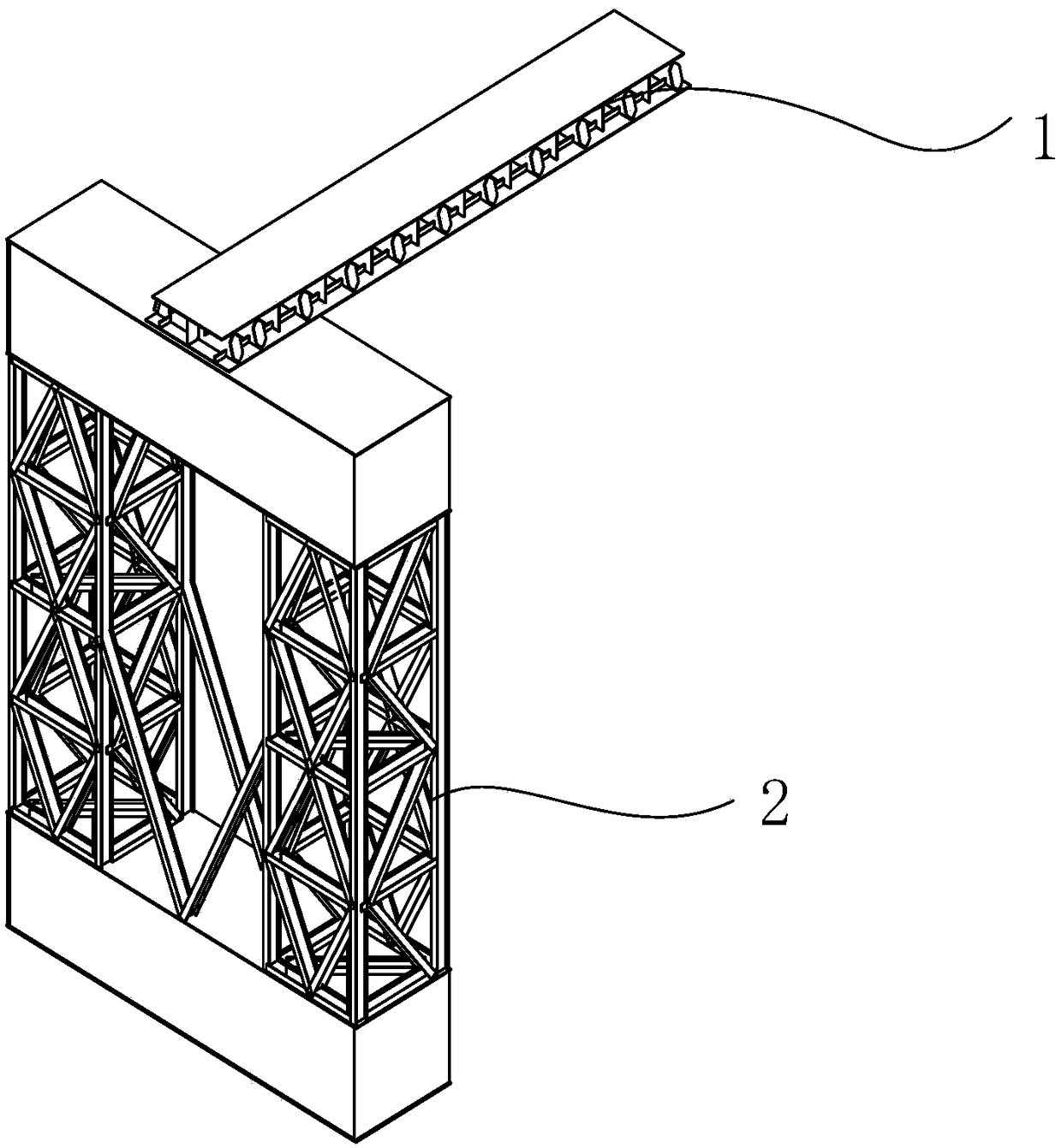

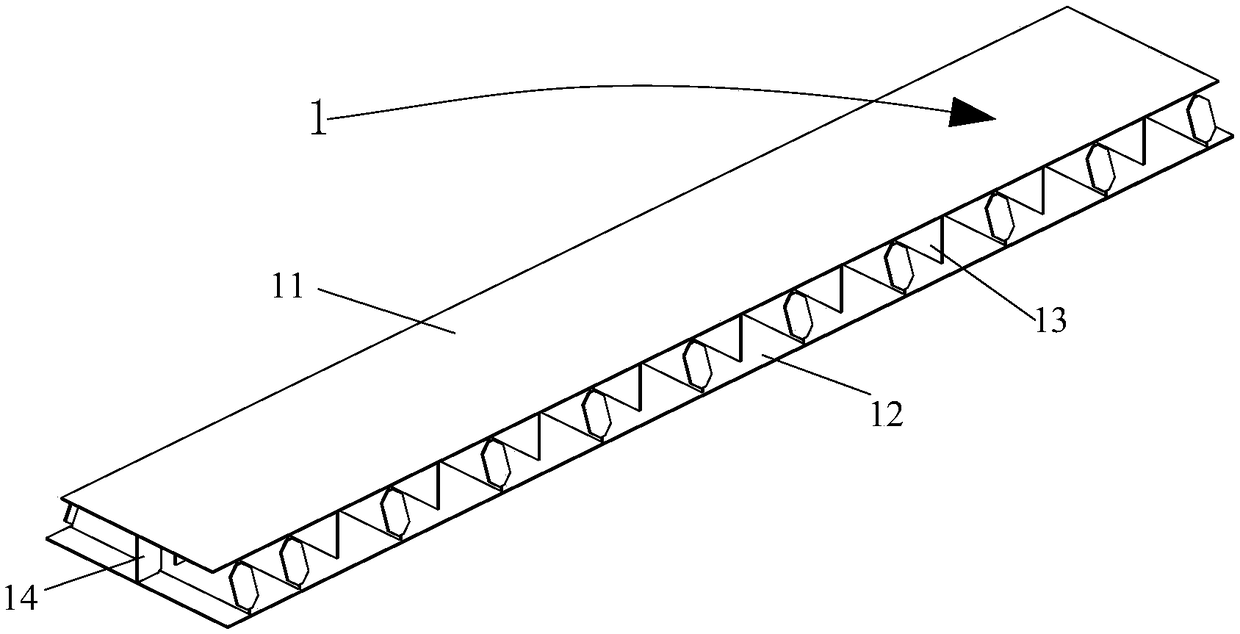

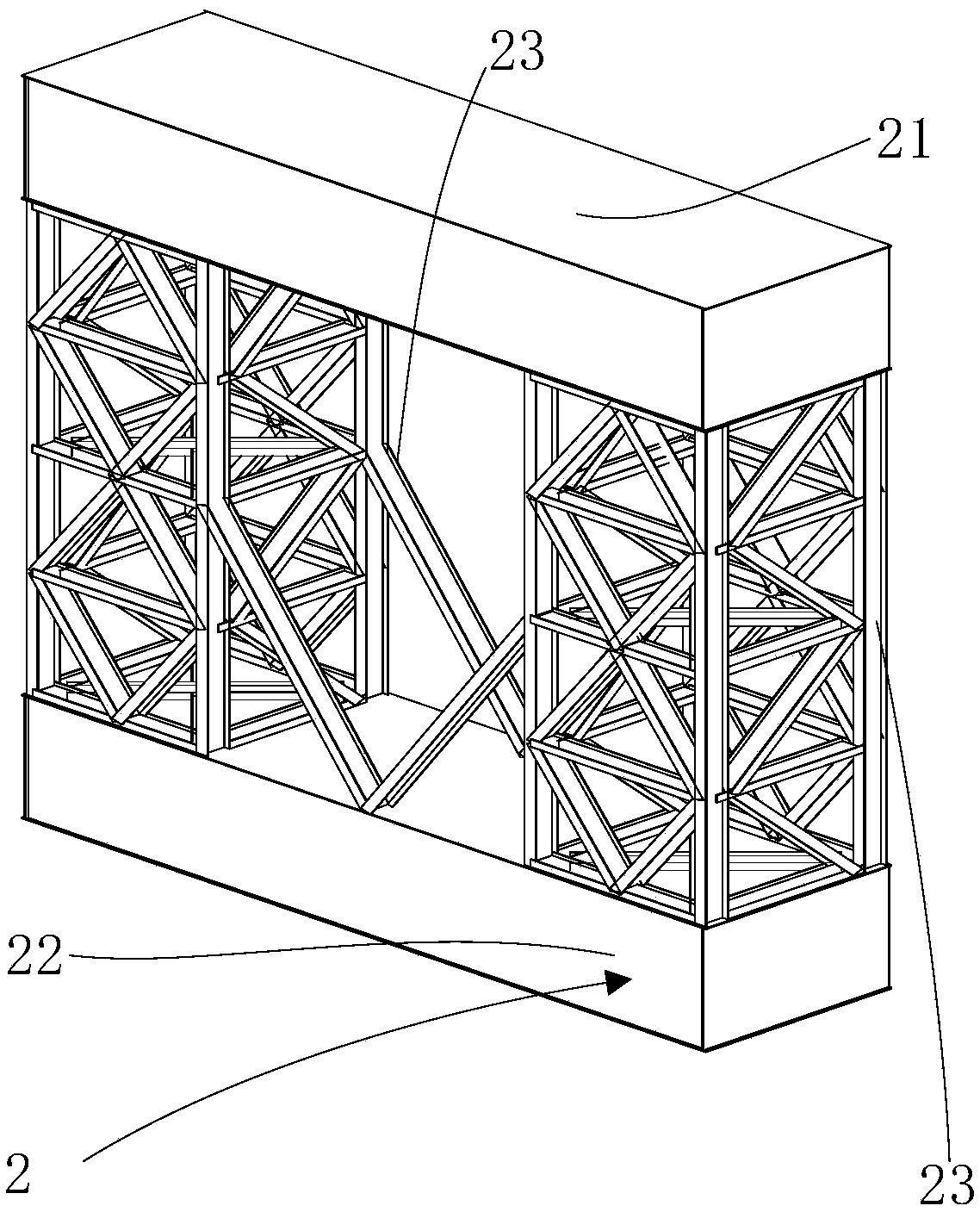

[0033] Such as Figure 1~3 As shown, the corridor protection tooling of this embodiment 1 includes a span beam 1 and several support frames 2; the span 1 beam includes an upper beam plate 11 and a lower beam plate 12 arranged in parallel, and the width of the upper beam plate 11 is smaller than that of the lower beam plate The width of 12, between the upper beam plate 11 and the lower beam plate 12, several partitions 13 are arranged along the length direction, and some partitions 14 are arranged along the width direction; the support frame 2 includes an upper box body 21, a lower box body 22, and The beam frame 23 placed between the upper box body and the lower box body; one end of the span beam 1 is placed on the top of the support frame 2 .

[0034] The lengths of the upper beam plate 11 and the lower beam plate 12 are both 10m; the width of the beam plate 11 is 1500mm, and the width of the lower beam plate 12 is 1800mm; the parallel setting distance between the upper beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com