Multifunctional trash can

A trash can and multi-functional technology, applied in the field of daily necessities, can solve the problems of single function, large amount of activated carbon, limited adsorption capacity of activated carbon, etc., and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

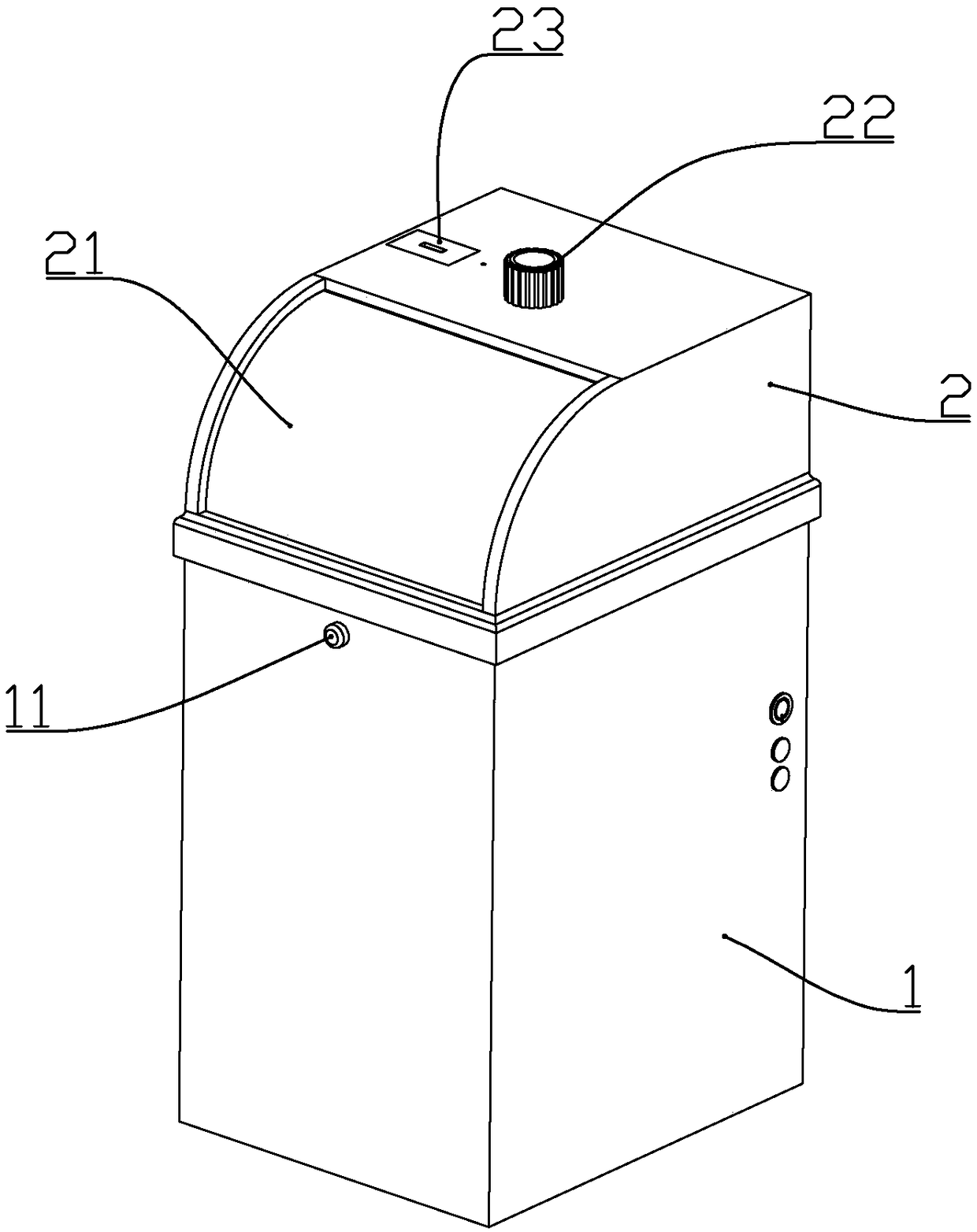

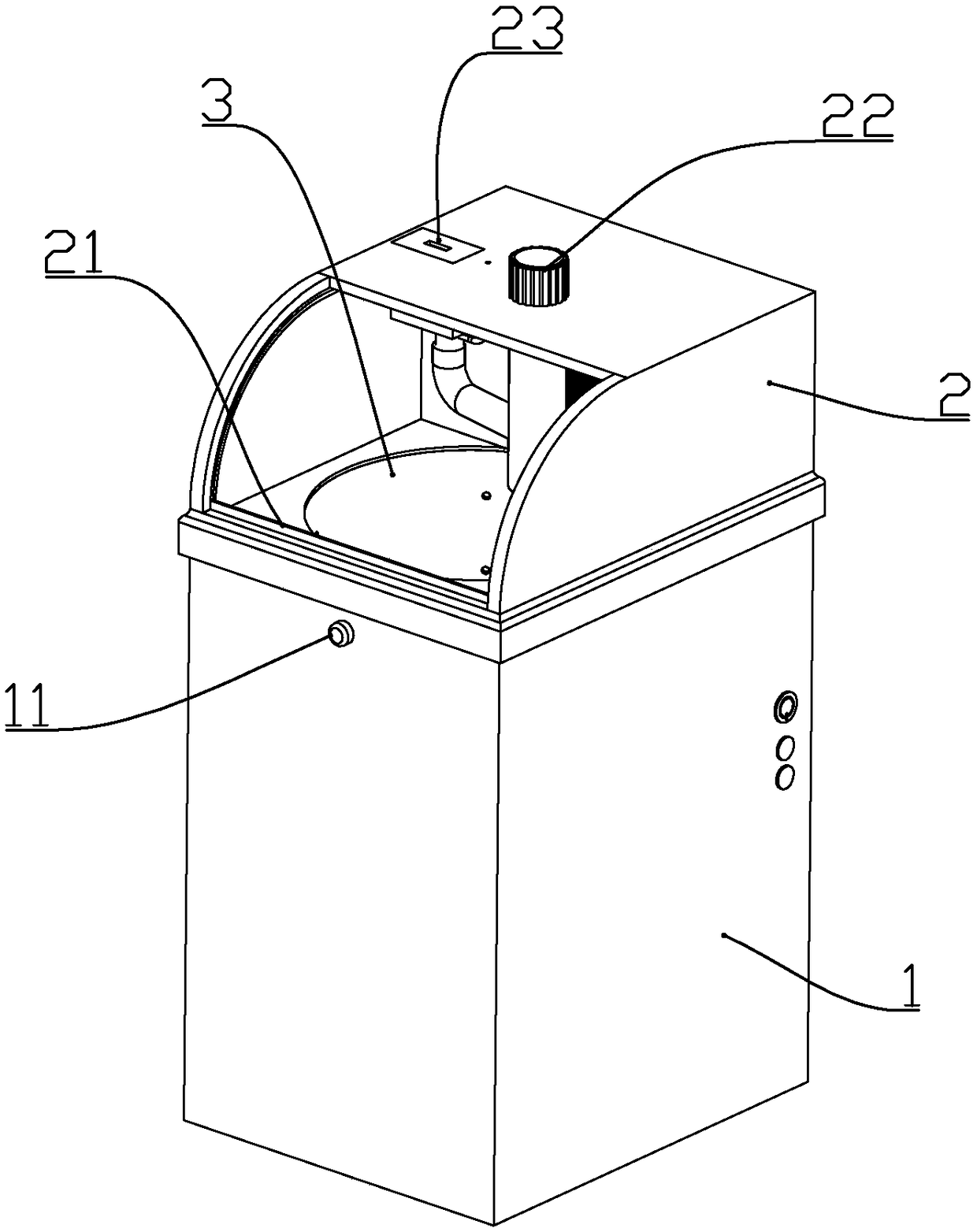

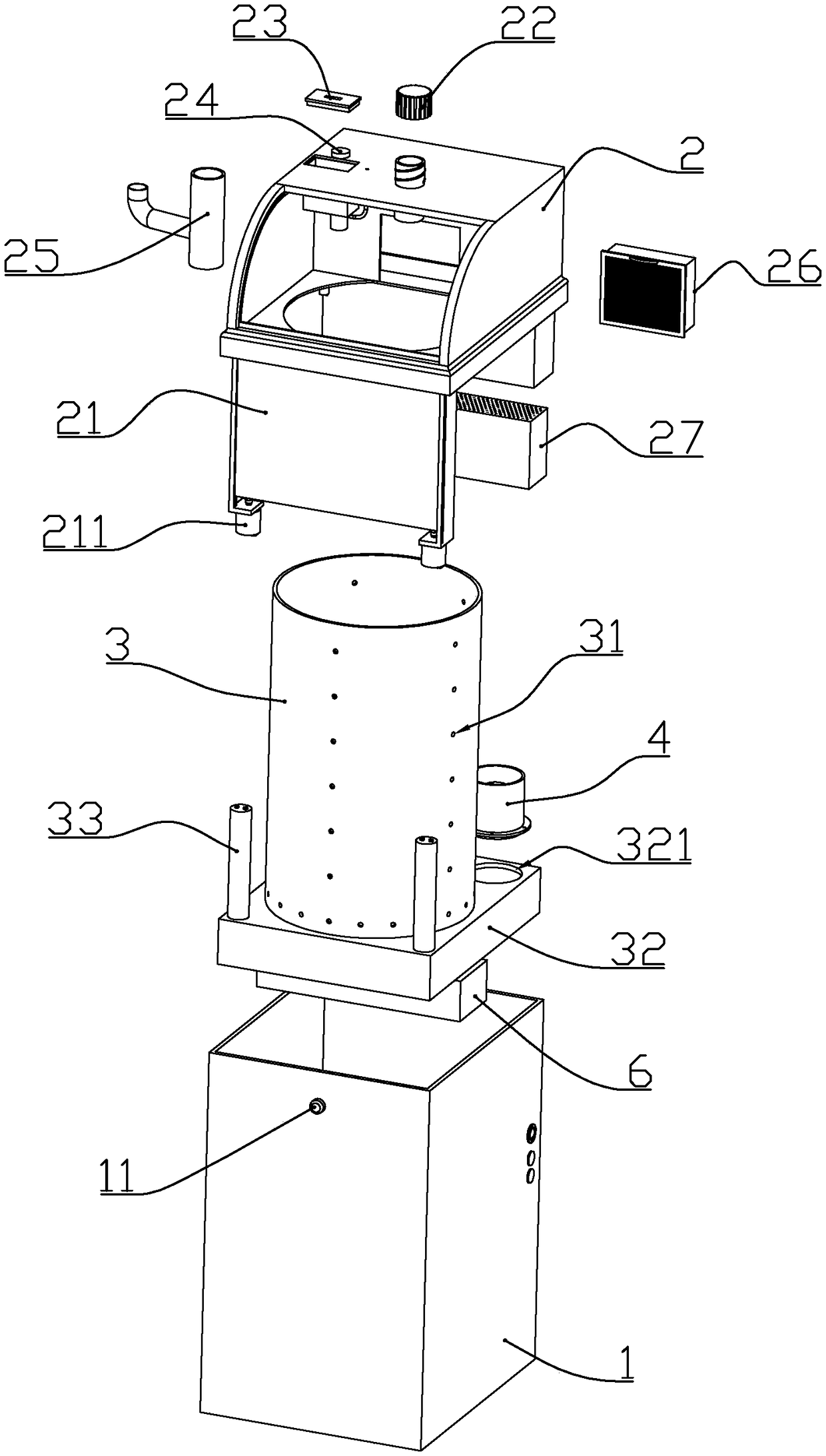

[0042] according to Figure 1 to Figure 8As shown, the present embodiment is a multifunctional trash can, comprising a cuboid-shaped outer barrel 1 with an open upper end, a cylindrical inner barrel 3 installed in the outer barrel from top to bottom, and a detachably sleeved upper end of the outer barrel The barrel lid 2.

[0043] The lower end of the inner barrel is integrally connected with a lower support 32 that matches the shape of the inner circumference of the outer barrel. Two fans 4 that supply air from top to bottom are installed on the upper end of the rear side of the lower support. A fan installation port 321 is formed at the position where the fan is installed; an air exhaust port 12 is formed at the lower end of the rear wall of the outer barrel, and the lower part of the lower support is connected to the air exhaust port.

[0044] The front upper part of the lid is formed with an arc-shaped garbage throwing inlet, and the two sides of the garbage throwing inle...

Embodiment 2

[0056] combine Figure 1 to Figure 10 As shown, the present embodiment makes the following improvements on the basis of embodiment 1:

[0057] A dust suction pipe 201 is formed on the lid above the inner barrel, and the upper end of the dust suction pipe is connected with a cover 22 through threads, or connected with a dust suction head 5 through a hose 51 .

[0058] An atomizing water tank 202 is formed at the top of the barrel cover at a position different from that of the suction pipe, and an ultrasonic microporous atomizer 24 is installed at the bottom of the atomizing water tank; There is a mist outlet pipe 2021, an air suction pipe 203 is connected to the side of the mist outlet pipe, and the other end of the air suction pipe extends outside the barrel cover; the upper end of the atomization water tank is connected to a water tank cover 23.

[0059] A humidification pipe 25 is connected to the lower end of the suction pipe, and the lower end of the humidification pipe i...

Embodiment 3

[0069] combine Figure 11 , Figure 12 In this embodiment, the following improvements are made on the basis of Embodiment 1 or 2: a support bead 35 is formed on the upper periphery of the inner barrel, and a rotating ring 7 is provided on the outer periphery of the inner barrel above the support bezel. The outer wall of the rotating ring 7 is formed with 5-8 groups of wheel seats 701, and each group of wheel seats is connected with a sticky wheel 702 made of thermoplastic material or soft silicone material through a pin shaft, and between the sticky wheel and the pin shaft is The interference fit makes the viscous wheel need to overcome the frictional force when rotating relative to the pin shaft; the outer wall of the rotating ring is located under the wheel seat and formed with driven teeth 703, and the inner wall of the outer barrel is equipped with a sealing motor 71 that drives the rotating ring to rotate , the output shaft of the sealing motor is connected with a drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com