Domestic garbage can

A trash can and garbage technology, applied in the field of daily necessities, can solve the problems of inconvenience, single function, limited adsorption capacity of activated carbon, etc., and achieve the effect of reducing clogging and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

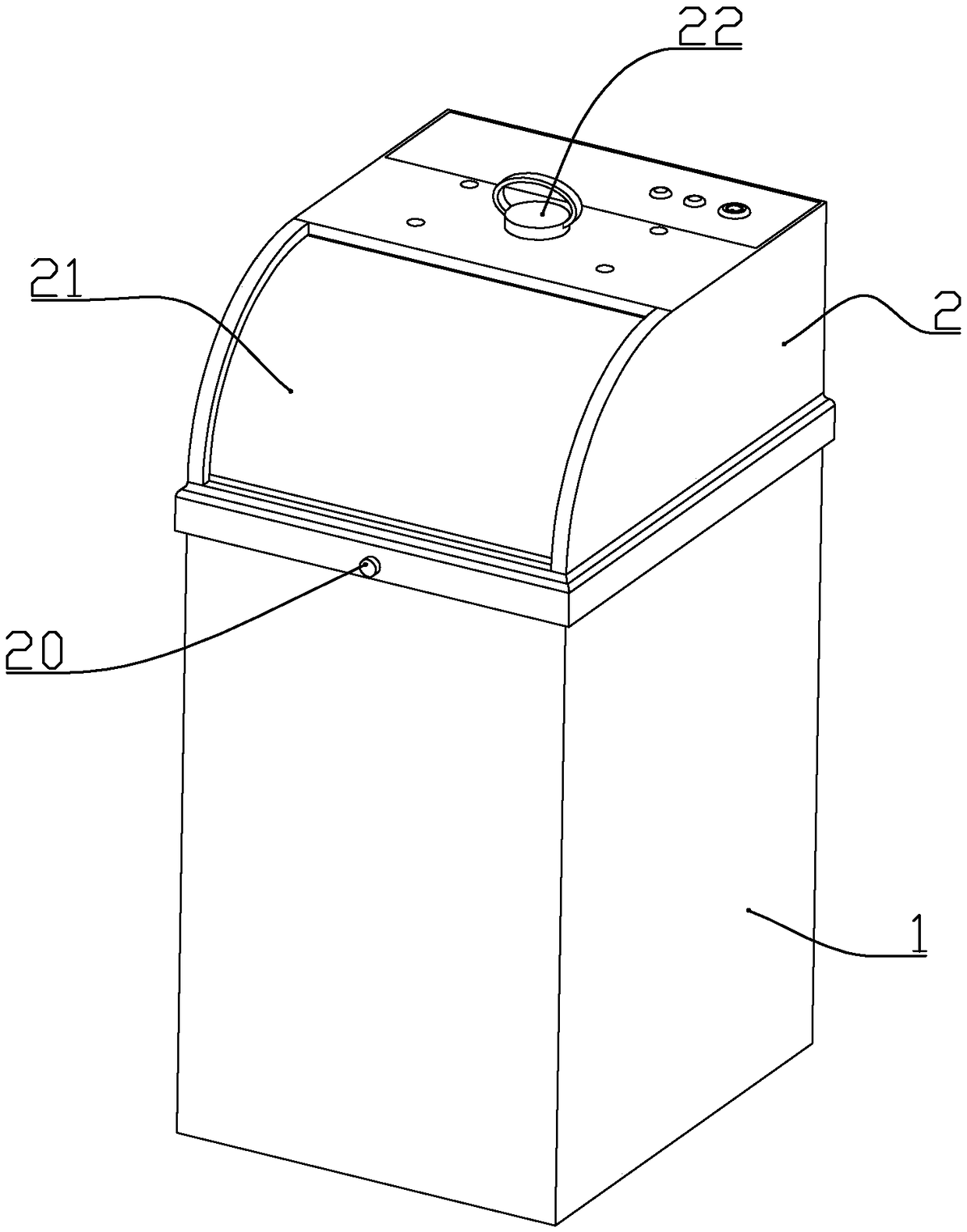

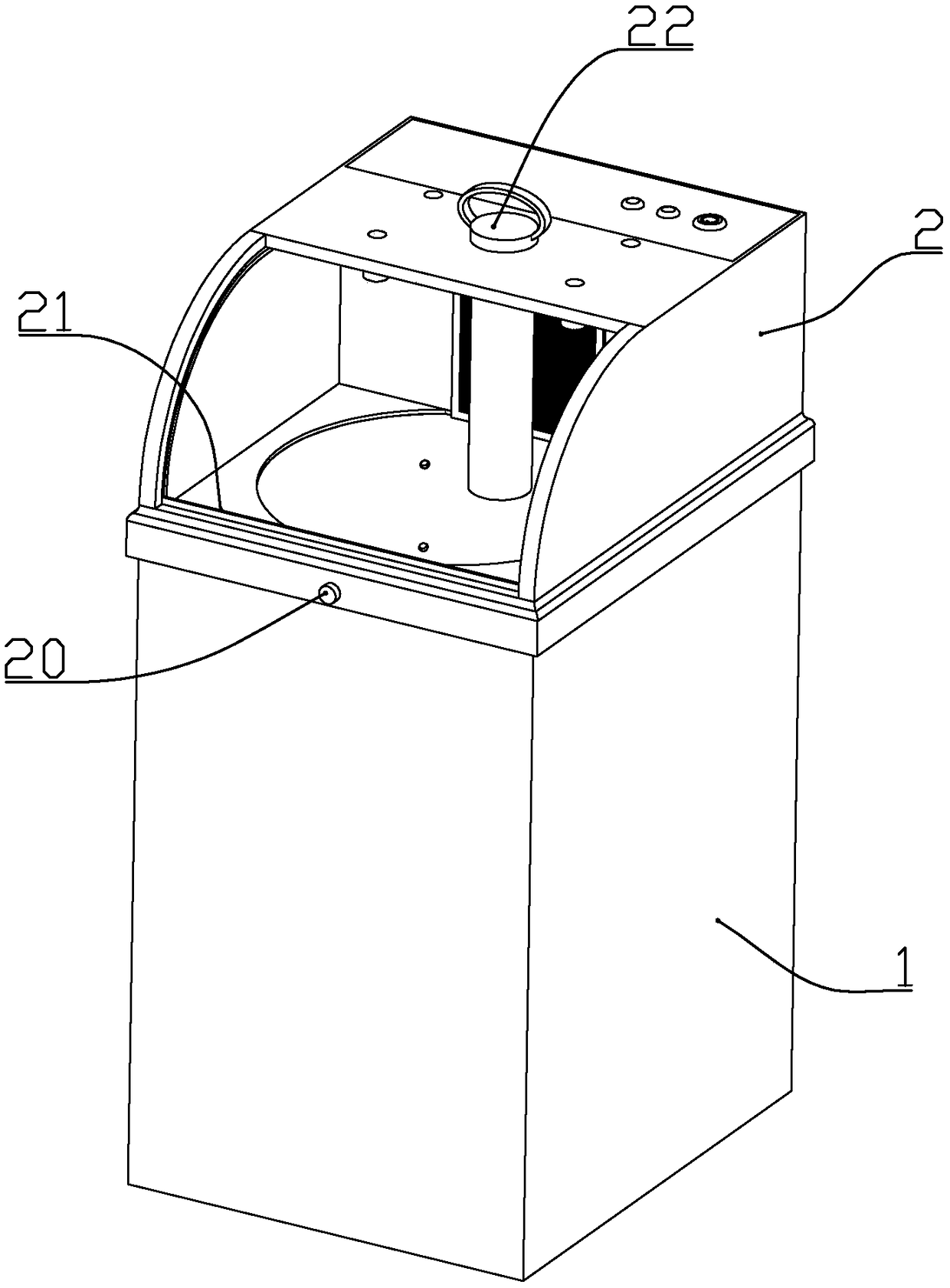

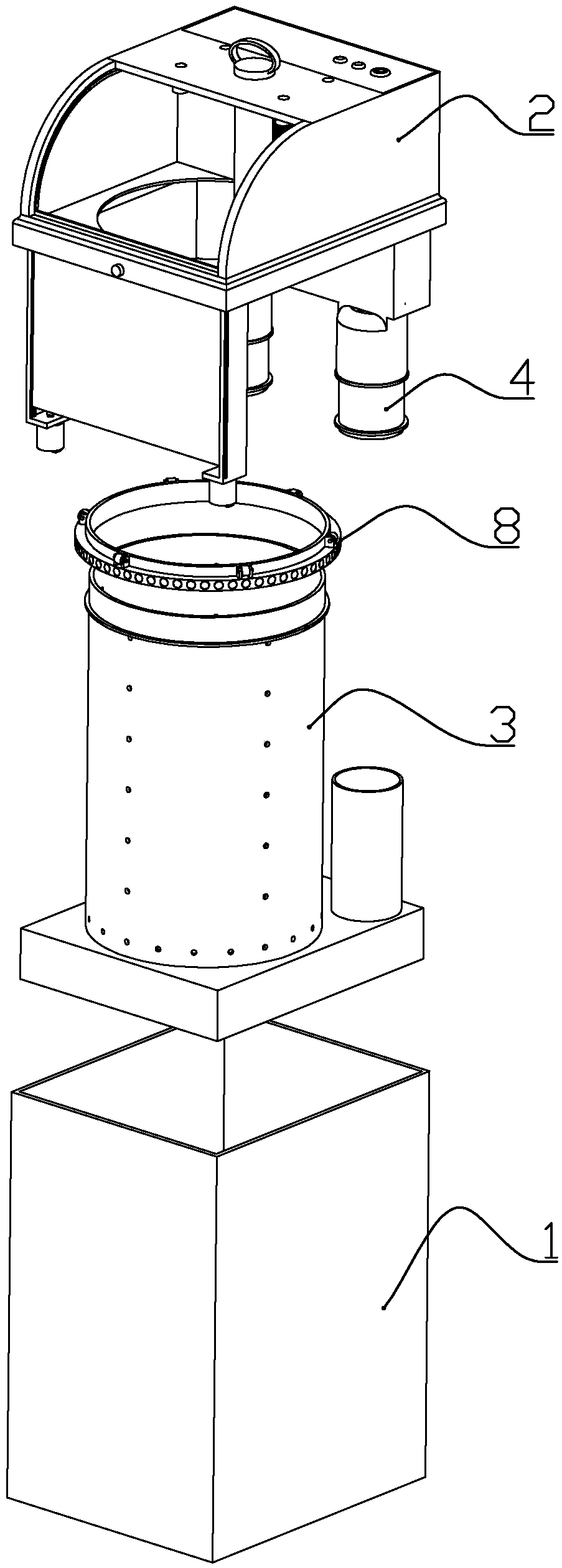

[0045] according to Figure 1 to Figure 9 As shown, the present embodiment is a household trash can, comprising a cuboid-shaped outer barrel 1 with an open upper end, a cylindrical inner barrel 3 installed in the outer barrel from top to bottom, and a detachably sleeved outer barrel on the upper end of the outer barrel. bucket lid2.

[0046] The front upper part of the lid is formed with an arc-shaped garbage throwing inlet, and the two sides of the garbage throwing inlet are symmetrically formed with baffle guide grooves 207 on the bung, and the two baffle guide grooves on both sides are slidably installed. There is an elastic baffle 21 in order to block the entrance of the garbage dump; two baffle mounting brackets 206 are formed at the corresponding baffle guide groove at the lower end of the front side of the bung, and the lower end of the baffle guide groove faces toward the Extending down to the bottom of the baffle mounting frame, the garbage throwing inlet is exposed ...

Embodiment 2

[0060] combine Figure 1 to Figure 12 As shown, the present embodiment makes the following improvements on the basis of embodiment 1:

[0061] The inner top of the bung is positioned above the inner bucket to form a suction pipe 201 that penetrates up and down. The upper end of the suction pipe is sealed and inserted with a plug 22 , or connected to the suction head 5 through a hose 51 .

[0062] The bottom of the outer barrel is equipped with rollers 12 for conveniently moving the trash can.

[0063] The lower end of the suction pipe is connected with an inner extension pipe 2011, and the lower end of the inner extension pipe extends below the mouth of the inner barrel, so that the humidified dust is discharged into the inner barrel from the lower end of the inner extension pipe, and the dust that enters the dust filter flows upwards Significantly reduced, prolonging the service life of the dust filter.

[0064] The humidification assembly 7 includes a water tank 71 and a w...

Embodiment 3

[0072] combine image 3 , Figure 13 with Figure 14 In this embodiment, the following improvements are made on the basis of Embodiment 1 or 2: a support bead 34 is formed on the upper periphery of the inner barrel, and a rotating ring 8 is provided on the outer periphery of the inner barrel above the support bezel. The outer wall of the rotating ring 8 is formed with 5-8 groups of wheel seats 801, and each group of wheel seats is rotatably connected with a sticky wheel 802 made of thermoplastic material or soft silicone material through a pin shaft. Between the sticky wheel and the pin shaft is The interference fit rotation connection makes the viscous wheel need to overcome the friction when rotating relative to the pin shaft; the outer wall of the rotation ring is located at the bottom of the wheel seat and equidistantly installed with driven magnets 803, and the inner barrel baffle of the barrel lid is located below the rotation ring A sealing motor 81 that drives the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com