Wire outlet mechanism making coil conveniently be placed on rack

A coil and lead frame technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of large coils, affecting the processing process, and mutual knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

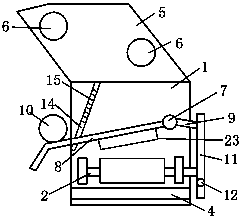

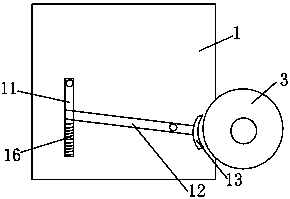

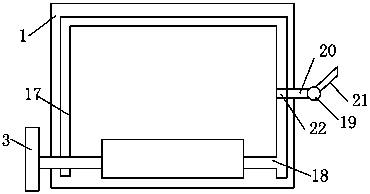

[0010] Combine below Figure 1 to Figure 3 Specific description embodiment:

[0011] The wire-out mechanism that is convenient for putting the coil on the shelf includes a frame 1, and a coil base 2 is provided at the lower part of the front side of the frame 1. The coil base includes an L-shaped frame 17, and the bottom of the L-shaped frame is hingedly arranged on the bottom of the frame. The lower part of the L-shaped frame is provided with a coil shaft groove 18, and the frame is provided with a pull-off lever 19. One side of the pull-off lever is provided with a clamping lever 20, and the other end of the pull-off lever is provided with a handle 21. L-shaped The frame is provided with a card slot 22 corresponding to the clamping rod; one end of the coil base is provided with a friction wheel 3; the rear lower part of the frame is provided with a driven roller 4; A lead frame 5 is provided, a lead wheel 6 is respectively arranged at both ends of the lead frame, and a trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com