Guiding device for spandex yarn dyeing

A technology of yarn dyeing and material guide device, which is applied in the field of spandex yarn dyeing, which can solve the problems of affecting the dyeing effect of the yarn, the process cannot be carried out, and the spandex yarn is broken, so as to avoid the phenomenon of inoperability, derailment and tearing The effect of breaking and moving up and down smoothly and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

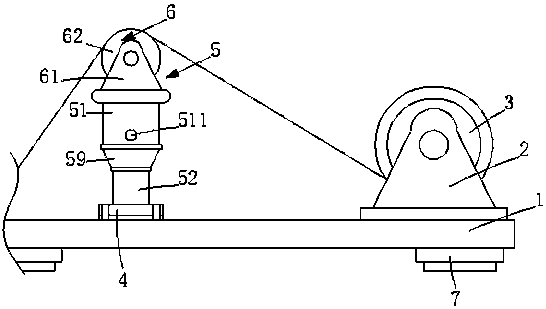

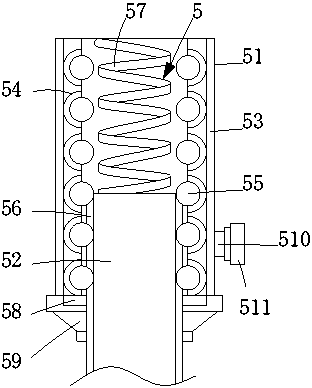

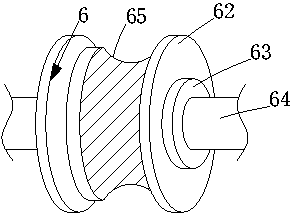

[0020] like Figure 1-3 As shown, the present invention provides a technical solution: a material guide device for spandex yarn dyeing, including a bottom plate 1, a mounting bracket 2, a pay-off roller 3, a mounting plate 4, a stress adjustment mechanism 5 and a yarn carrying mechanism 6. The bottom of the mounting bracket 2 is fixedly connected to the right side of the top of the base plate 1, the middle position of the front and back of the pay-off roller 3 is connected to the top of the front and back of the mounting bracket 2 through a rotating shaft, and the bottom of the mounting plate 4 is connected to the base plate through bolts 1. The middle position of the top is fixedly connected, the top of the mounting plate 4 is fixedly connected with the bottom of the stress adjustment mechanism 5, the bottom of the yarn loading mechanism 6 is fixedly connected with the top of the stress adjustment mechanism 5, and the bottom of the bottom plate 1 is fixedly connected with a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com