Winding mechanism and power cable winding equipment

A technology of winding mechanism and power cable, which is applied in the field of power cables, can solve problems such as complex structure, inconvenient disassembly and maintenance, and inability to clean cables, and achieve the effect of easy use, convenient disassembly and fixation, and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

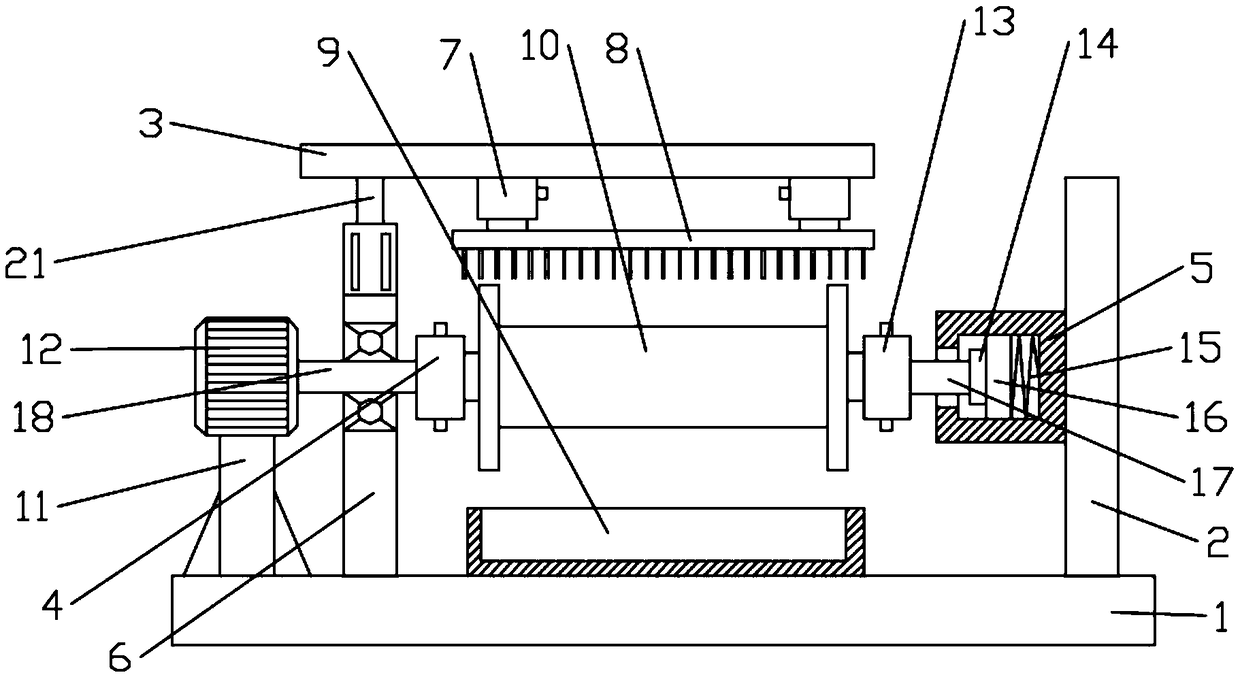

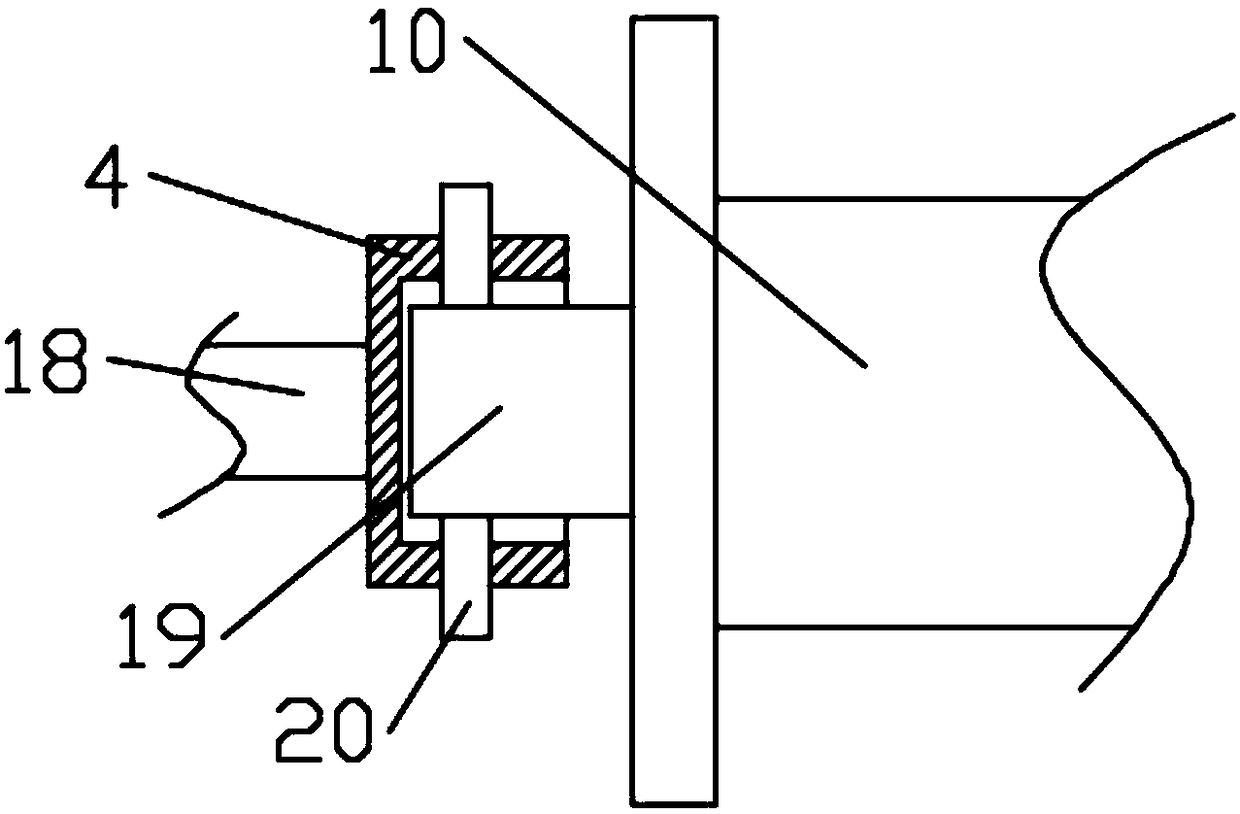

[0022] see figure 1 and figure 2 , in an embodiment of the present invention, a winding mechanism includes a reel 10 and a motor 12 for driving the reel 10 to rotate, and the two ends of the reel 10 respectively pass through the first connection assembly 4 and the second connection assembly 13 Detachable and fixedly installed on the end of the rotating rod 18 and the end of the sliding rod 17, wherein the sliding rod 17 is elastically connected and installed on the first base 5, between the other end of the rotating rod 18 and the output shaft of the motor 12 Drive connection via coupling.

[0023] In the embodiment of the present invention, a cylindrical cavity is provided inside the first base 5, and a first slider 16 cooperating with the cylindrical cavity is slidably arranged in the cylindrical cavity. A first compression spring 15 is provided; a bearing seat 14 is fixedly installed on the left end surface of the first slider 16; the bearing seat 14 is rotationally conn...

Embodiment 2

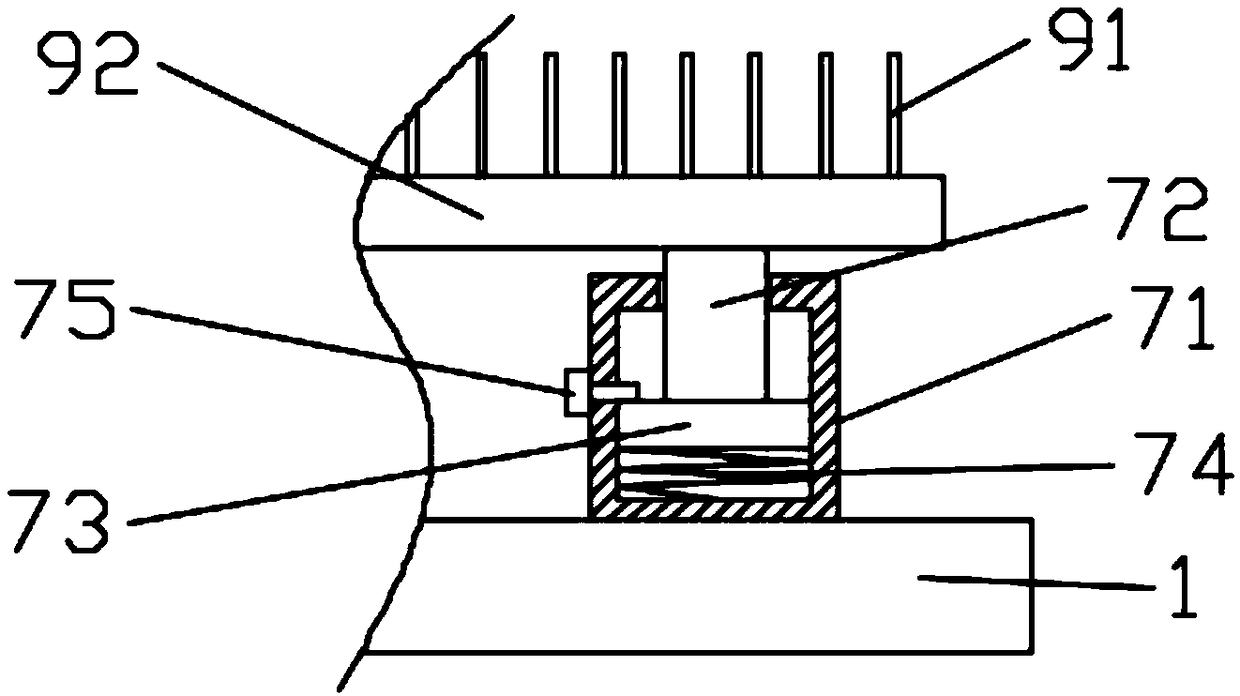

[0031] Unlike Example 1, see figure 1 and image 3 , in the embodiment of the present invention, the cleaning assembly 8 includes the elastic support assembly 7 and the cleaning plate 92 installed on the bottom of the elastic support assembly 7, the lower surface of the cleaning plate 92 is provided with a cleaning brush 91, wherein the elastic support assembly 7 is installed On the lower surface of the support top plate 3, the elastic support assembly 7 includes a second base 71, a support rod 72, a second slider 73, a second spring 74 and a shaft pin 75; the inside of the second base 71 A cylindrical cavity is provided, and a second slider 73 is slidably arranged in the cylindrical cavity, and a second spring 74 is arranged at the bottom of the second slider 73, and the bottom end of the support rod 72 is fixed to the upper surface of the second slider 73 In connection, the outer wall of the second base 71 is also processed with a threaded through hole, and a shaft pin 75 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com