Manual sliding plug door mechanism

A technology for carrying door frames and components, which is applied in the field of manual sliding door mechanisms, can solve the problems such as the inability of the weight to meet the use requirements, the inconvenient opening and closing methods, and the complex structure, and achieves good application prospects, light weight and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

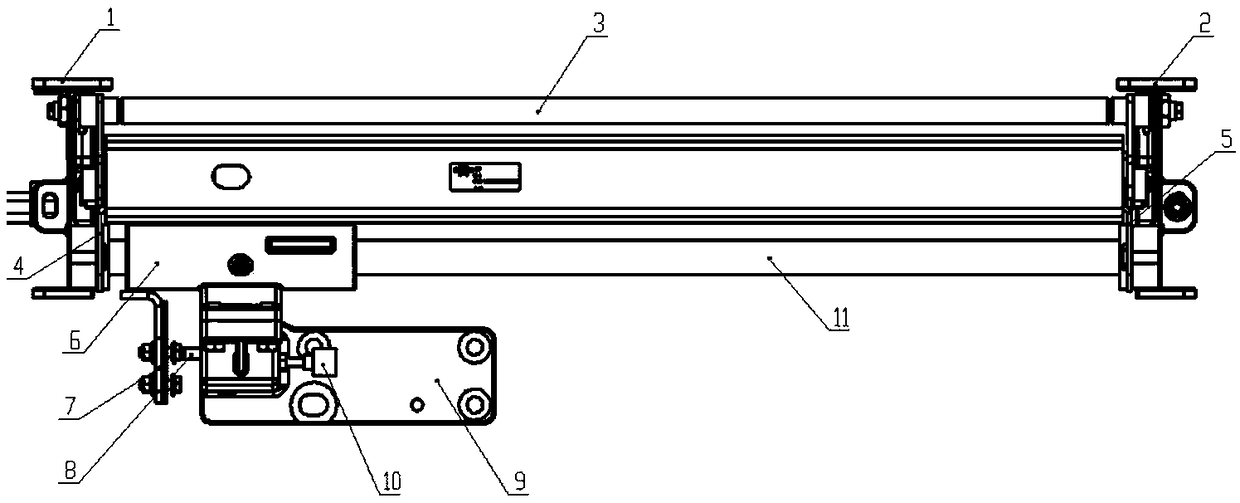

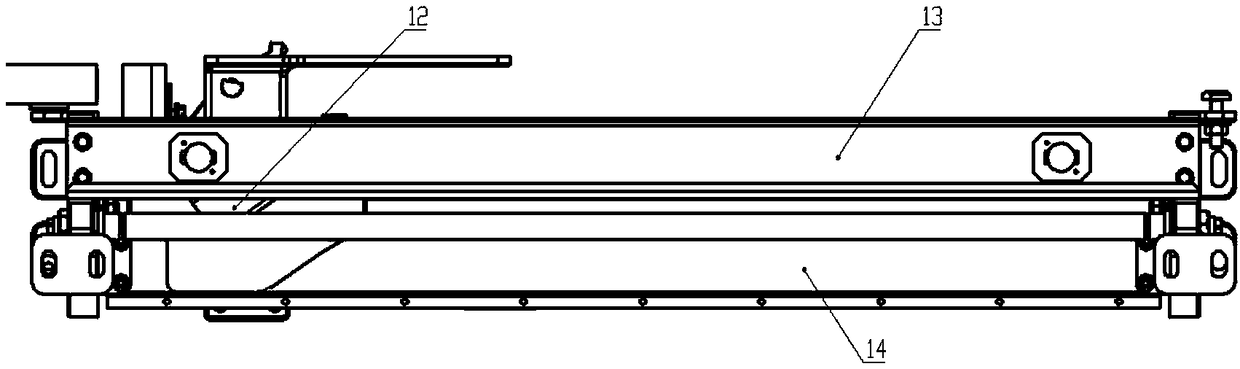

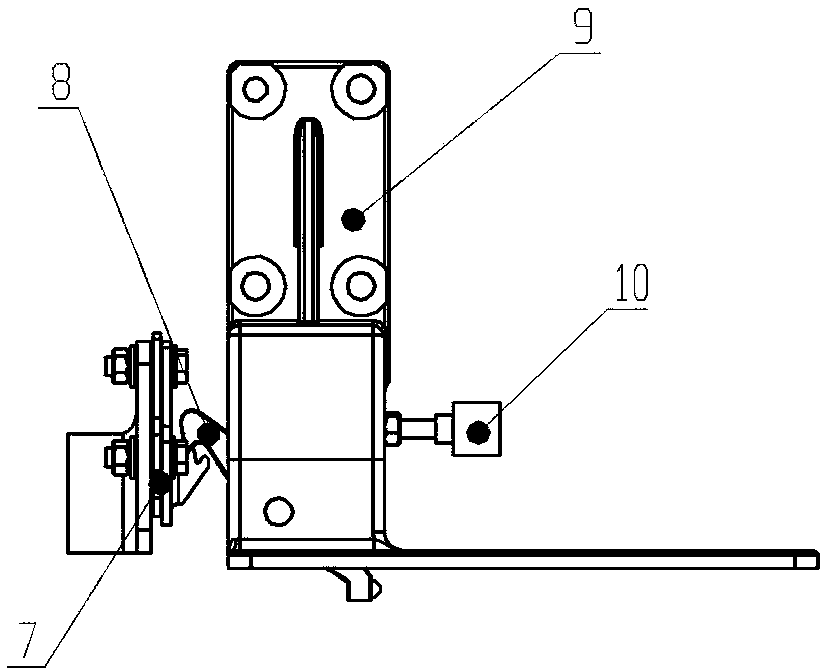

[0020] As shown in the figure, a manual sliding door mechanism includes: left bracket 1, right bracket 2, synchronous rod 3; left hanger plate assembly 4, right hanger plate assembly 5, sliding cylinder assembly 6, lock baffle 7, Lock hook 8, door carrying frame 9, buffer head 10, long guide column assembly 11, upper slideway 12, fixing frame 13; bearing bracket 14.

[0021] The left bracket 1 and the right bracket 2 are fixed on the vehicle body, and there are slide grooves under the left bracket 1 and the right bracket 2; the left and right brackets can meet different installation methods such as dragging and hoisting at the same time, and the installation is convenient and reliable, and the adaptability is strong. The left bracket 1 and the right bracket 2 are connected by a fixed frame 13 to achieve the purpose of connecting the mechanism as a whole, while the upper slideway 12 is fixed on the fixed frame 13 to make the structure compact.

[0022] The two ends of the long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com