Load detecting device

A technology for detecting equipment and loads, applied in mechanical equipment, measuring force, measuring devices, etc., can solve the problems of difficult detection work, difficult direct implementation of hand-held detection, and affecting bolt performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

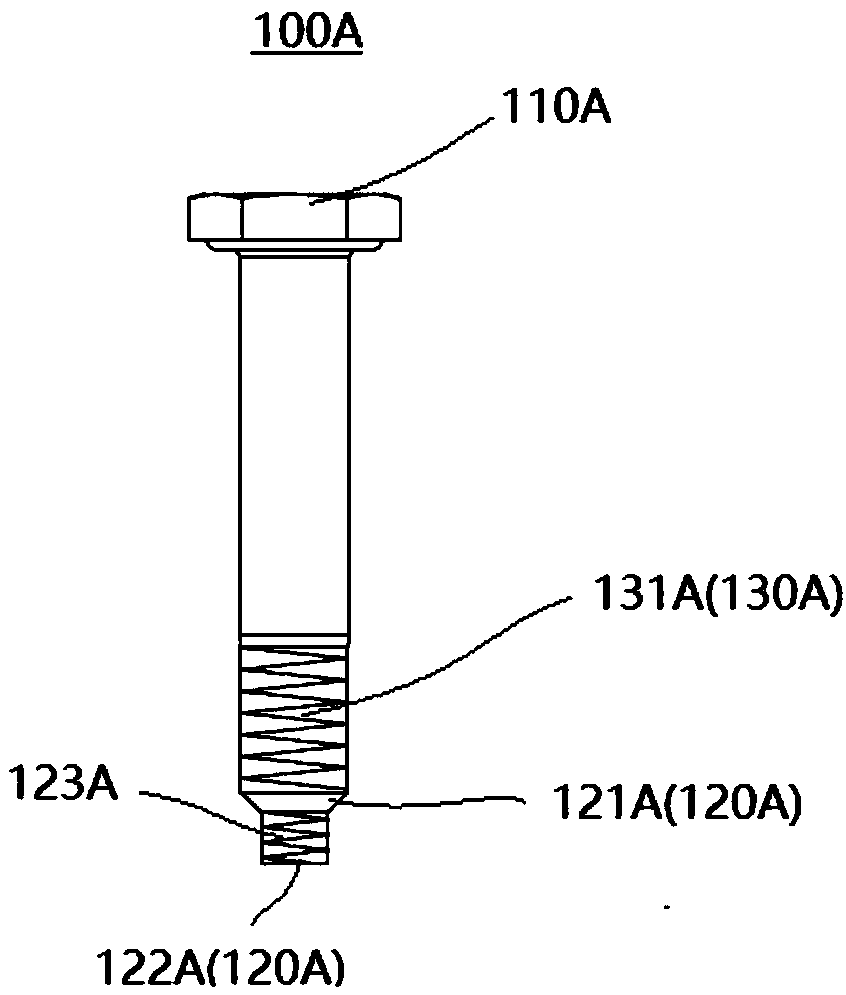

[0084] Hereinafter, referring to Fig. 2(a), Fig. 2(b), Fig. 3(a), Fig. 3(b), Fig. 4(a), Fig. 4(b), Fig. 5(a), Fig. 5(b) , Fig. 6 (a), Fig. 6 (b), Fig. 7 (a), Fig. 7 (b), in conjunction with Fig. 1 (a), the bolt standard part 10 of the prior art shown in Fig. 1 (b), to this The non-standard bolts 100A, 100B, 100C, 100D, 100E, and 100F that can be directly equipped with load detection equipment in the first to sixth embodiments of the invention will be described in detail.

[0085] (bolt standard part 100 of the prior art)

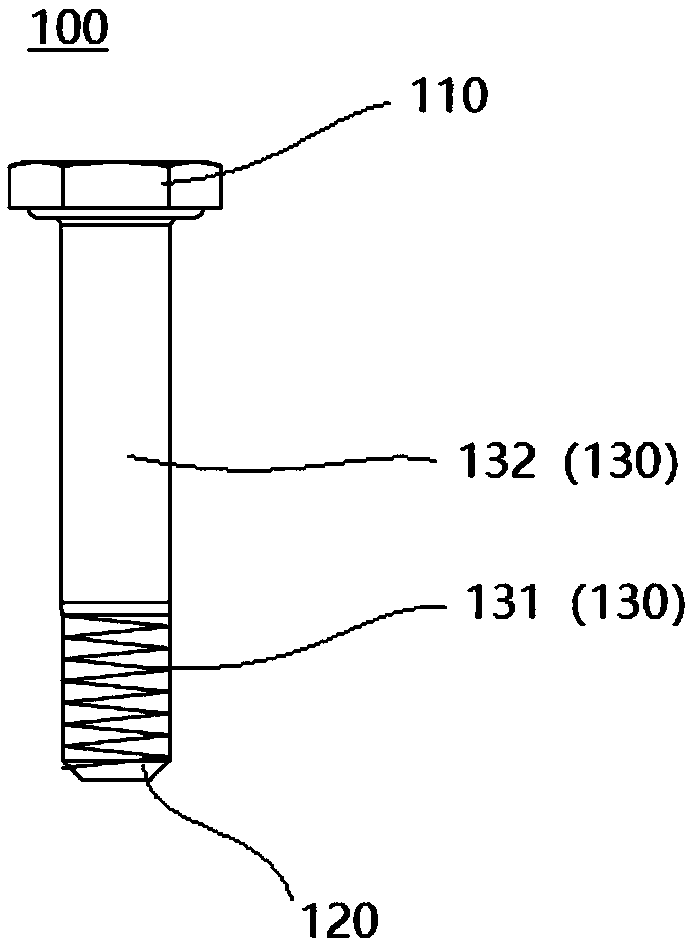

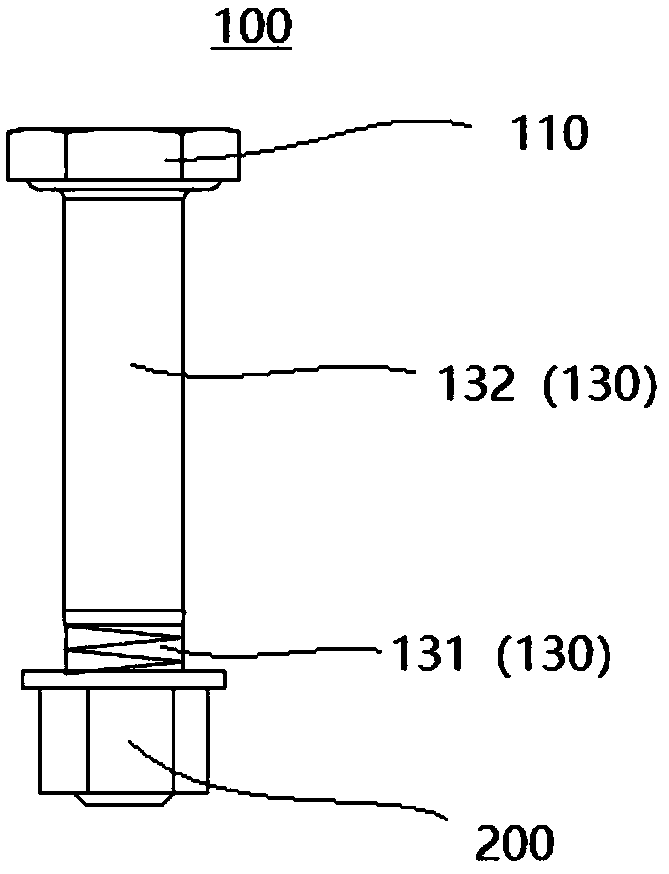

[0086] FIG. 1( a ) is a schematic diagram showing a bolt standard 100 in the prior art, and FIG. 1( b ) is a schematic diagram showing a state in which the bolt standard 100 and the nut standard 200 in the prior art are screwed together.

[0087] As shown in FIG. 1( a ), a standard bolt 100 in the prior art includes a bolt head 110 , a bolt tail 120 and a screw rod 130 .

[0088] In the bolt standard 100 shown in FIG. 1( a ), the bolt head 110 is formed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com