Gas generating device and virtual olfactory system

A technology of gas generation and odor generation, which is applied in the direction of gas generation devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of single odor, low efficiency of odor delivery, and insufficient immediacy, and achieve low efficiency and shortened time Generate time and solve the effect of insufficient immediacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

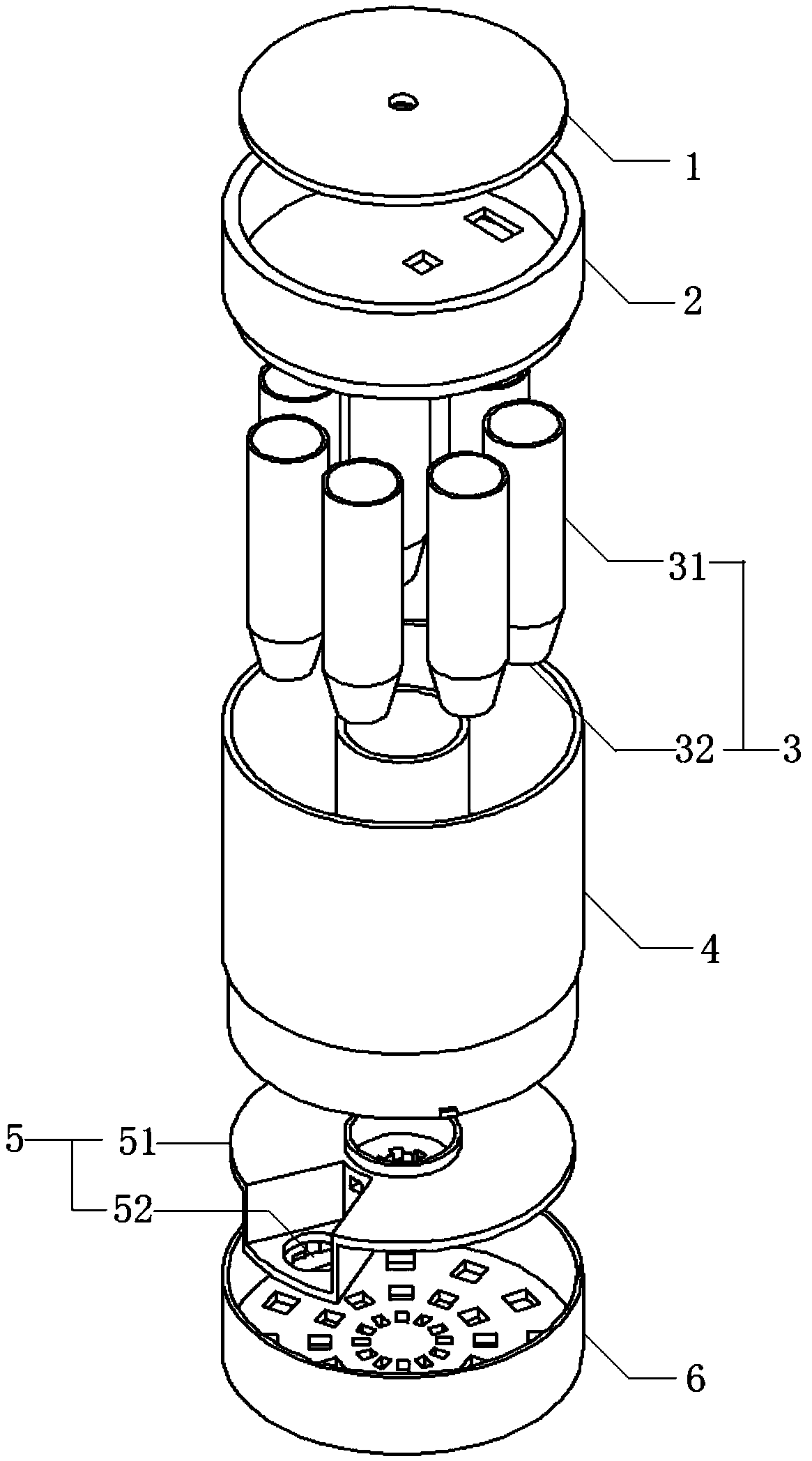

[0030] Example 1, see Figure 1-5 :

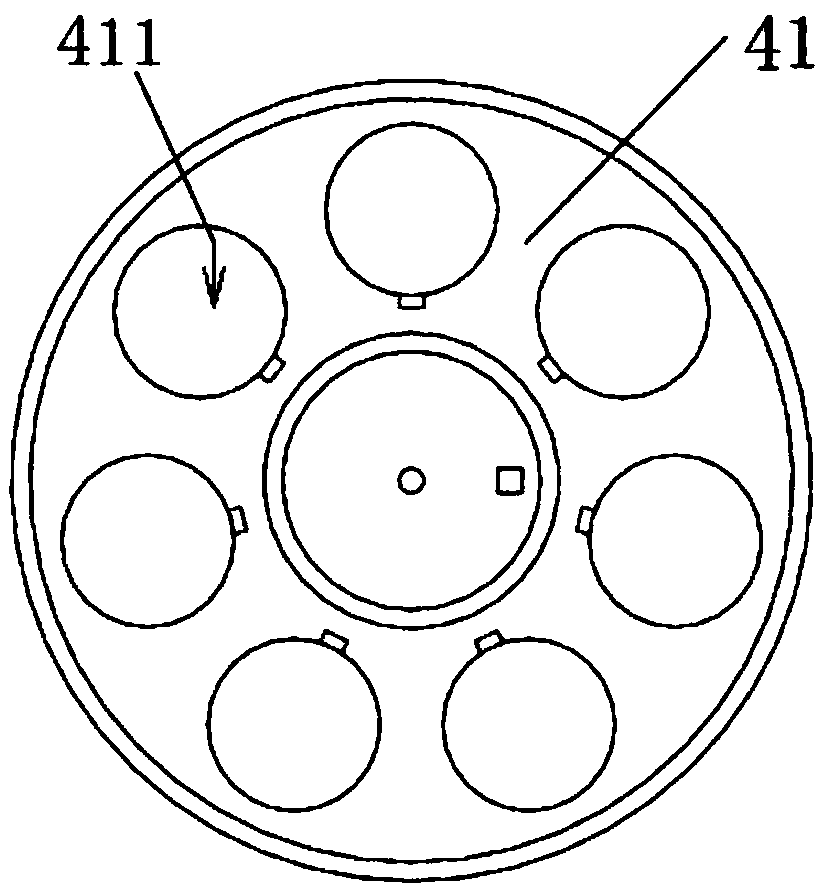

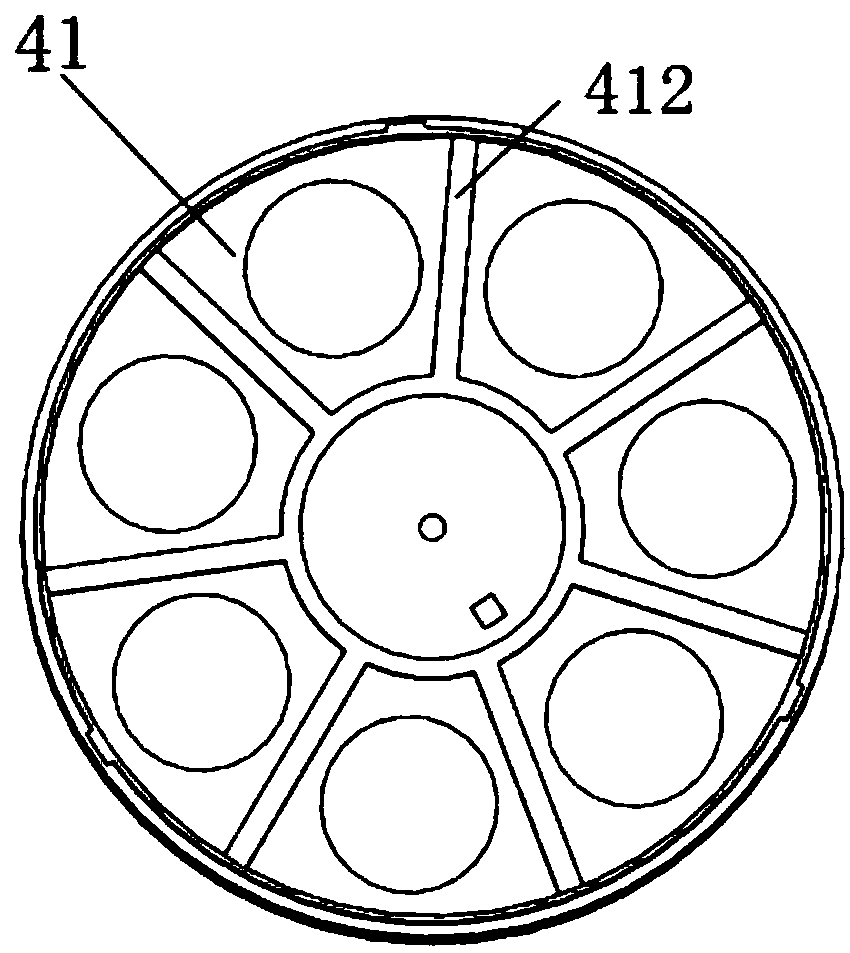

[0031] An odor generating device, comprising 8 gas generating components 3, a housing enclosing the gas generating components 3, a gas delivery component 5 wrapped in the housing and located below the gas generating components 3, and a body 4 located above the housing and covered upper control module layer 2, such as figure 1 shown. In other embodiments, the number of gas generating components 3 can be adjusted as required.

[0032] Wherein, the gas generating assembly 3 includes an odor container 31 and a microporous atomizing sheet 32 located at the bottom of the odor container 31, the microporous atomizing sheet 32 plays the role of sealing the bottom of the odor container 31 in a non-working state, and the microporous atomizing sheet 32 plays the role of sealing the bottom of the odor container 31, The sheet 32 and the odor container 31 together form a container for carrying a liquid that can produce a specific odor. Differe...

Embodiment 2

[0045] Example 2, see Image 6 :

[0046] A virtual olfactory system, comprising the above-mentioned odor generating device and a host computer, the host computer and the odor generating device are connected in communication, the host computer sends an odor generating request to the odor generating device according to the received scene identification, and the gas generating request includes a predetermined gas number. The control template layer 2 of the odor generating device also includes a lower computer, which receives odor requests, and the control device generates odors corresponding to the scene identification. In this embodiment, the upper computer is a host computer, and the lower computer is an arduino control module. Among them, the upper and lower computers communicate through the WiFi module, and the WIFI module is designed on the lower computer to receive the data transmitted from the upper computer. The WiFi module is the communication module between the compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com