Electric welding device capable of realizing cooling protection

A technology of electric welding equipment and electric push rod, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of slow cooling process, scald, heat stroke, etc., and achieve high flexibility, avoid damage, and quickly cool down. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

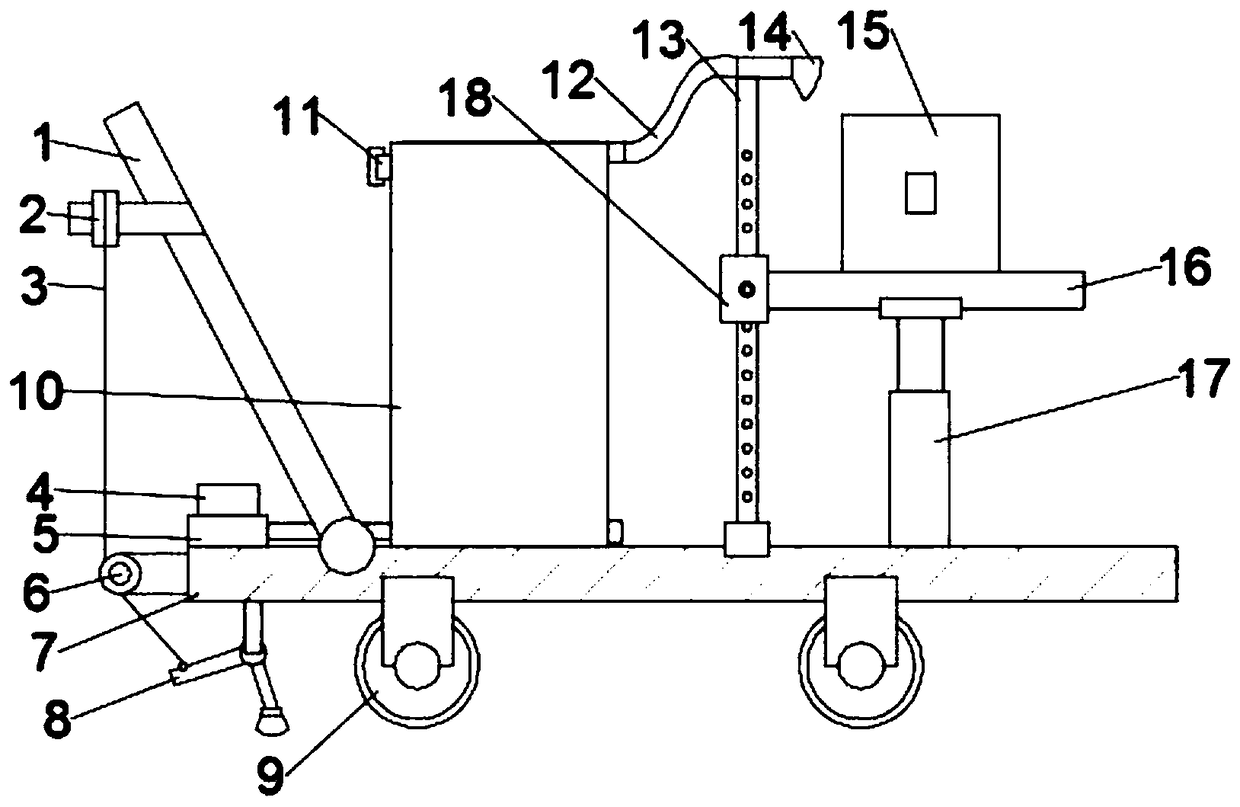

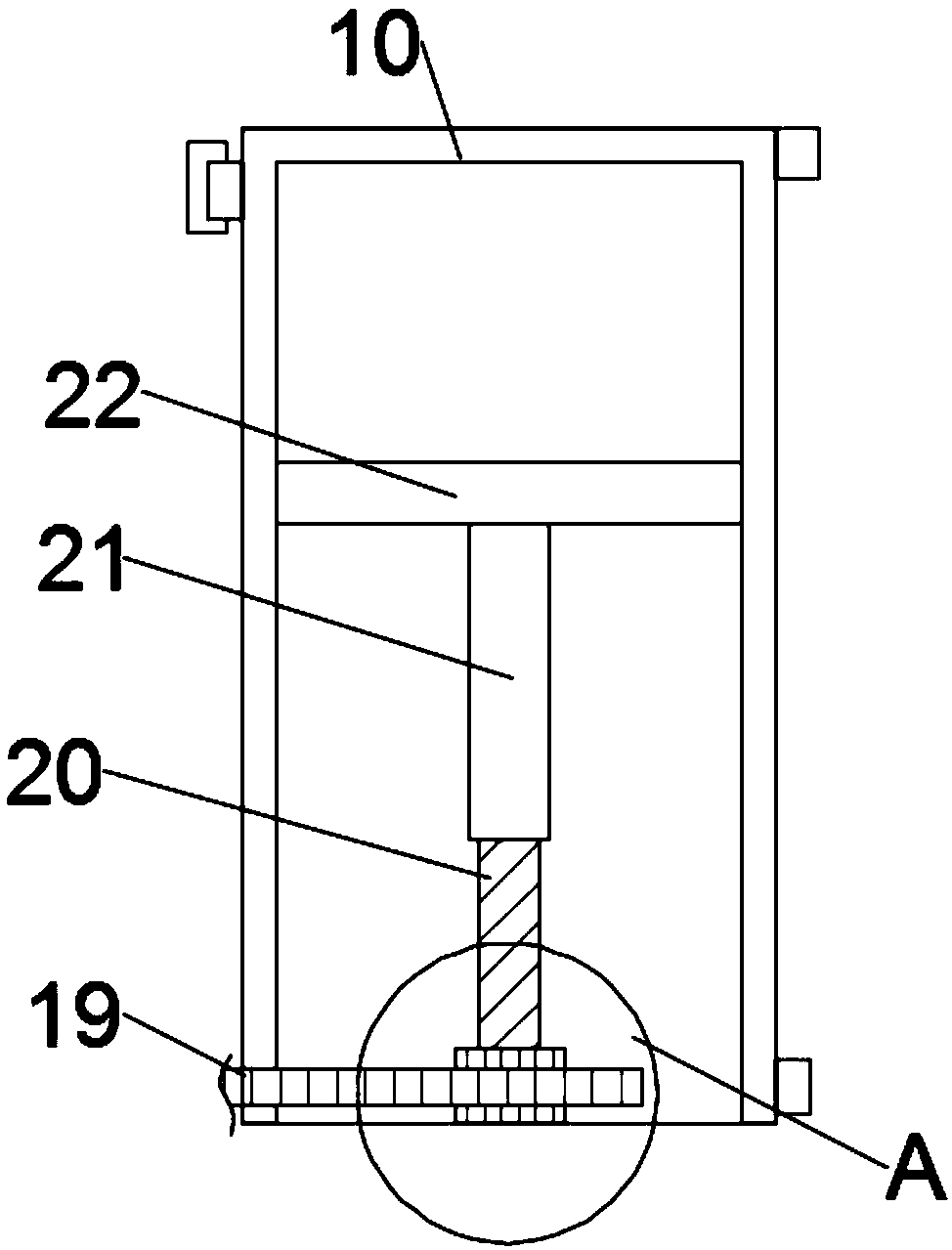

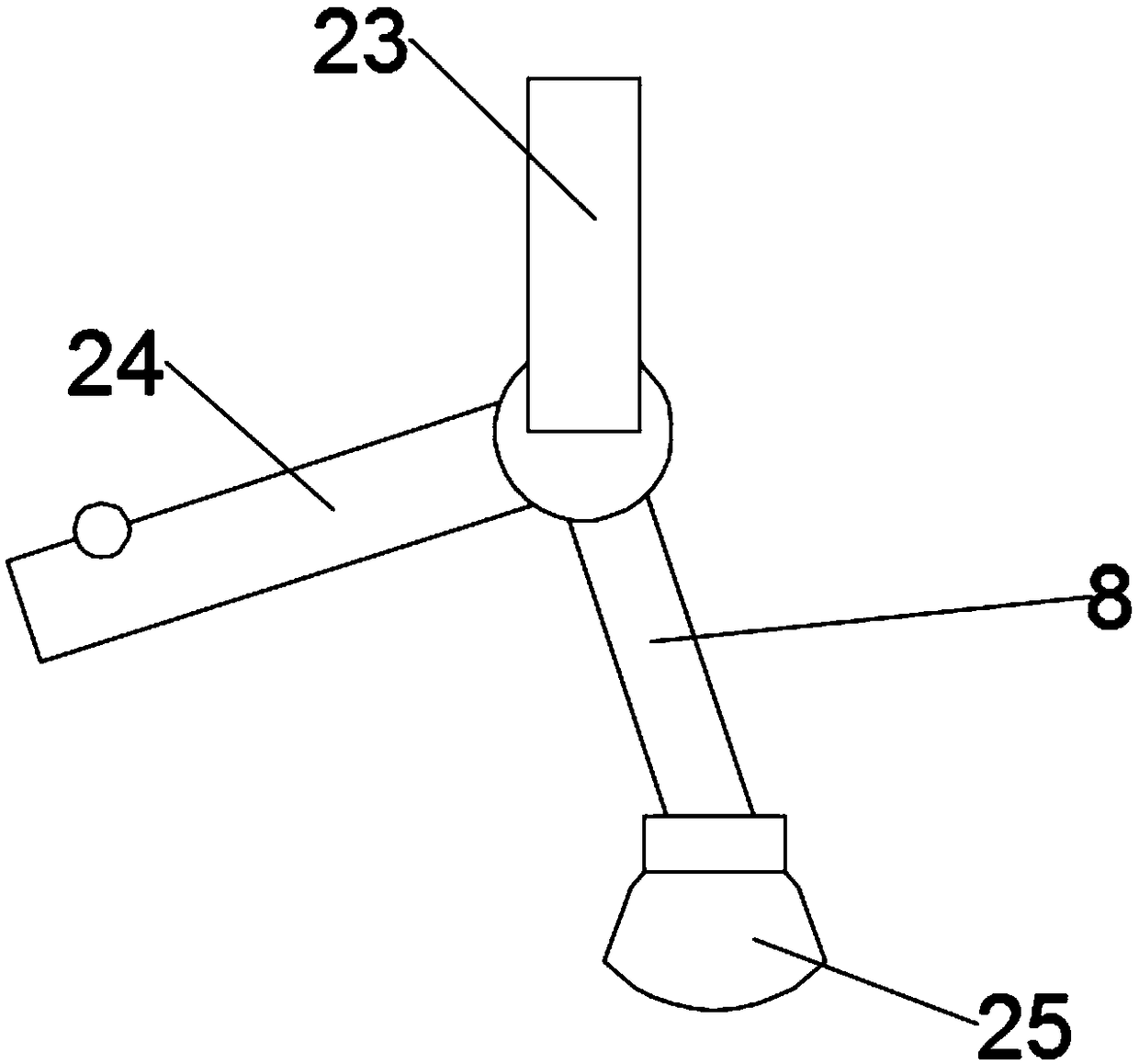

[0020] see Figure 1~4 , in the embodiment of the present invention, an electric welding equipment capable of realizing cooling protection, including a baffle 1, a base 7, a cold air release chamber 10 and an electric welding equipment 15, the lower end of the baffle 1 is fixed on the base 7, and the base 7 The cold air release chamber 10 is fixedly installed on the left side of the upper surface, and the limit plate 13 is fixedly installed on the right side of the cold air release chamber 10. The electric welding equipment 15 is arranged on the right side of the limit plate 13, and the lower part of the electric welding equipment 15 is fixed and installed on the On the workbench 16, a welding hydraulic cylinder 17 is fixed in the middle of the lower surface of the workbench 16, and the lower part of the hydraulic cylinder 17 is fixed on the right side of the upper surface of the base 7, and the hydraulic cylinder 17 starts to drive the workbench 16 Moving up and down can real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com