Auxiliary device and method for engine gear tightening

An auxiliary device and engine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the bolt torque cannot be guaranteed, the quality of the engine is affected, and the crowbar is easy to hurt people, etc., so as to improve assembly efficiency and production safety High performance, compact structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

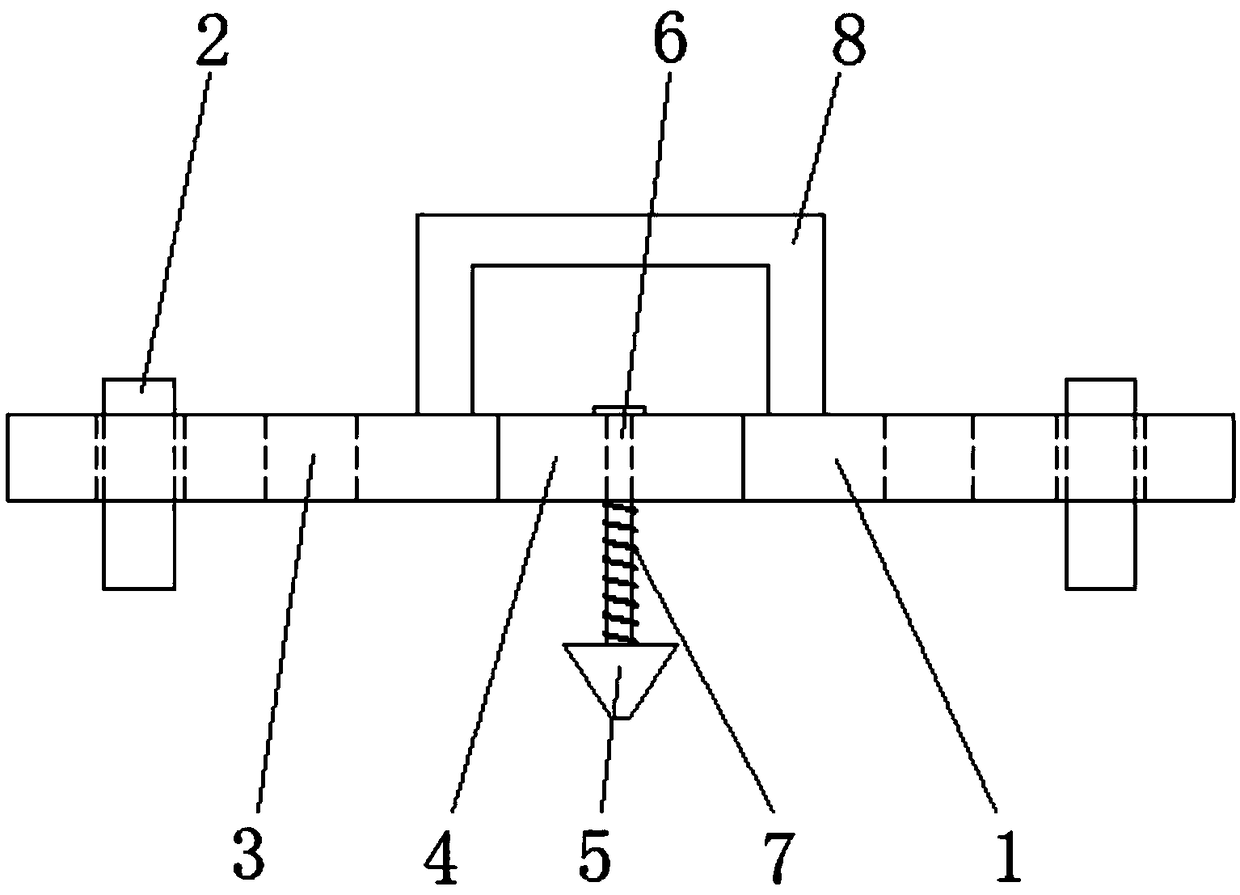

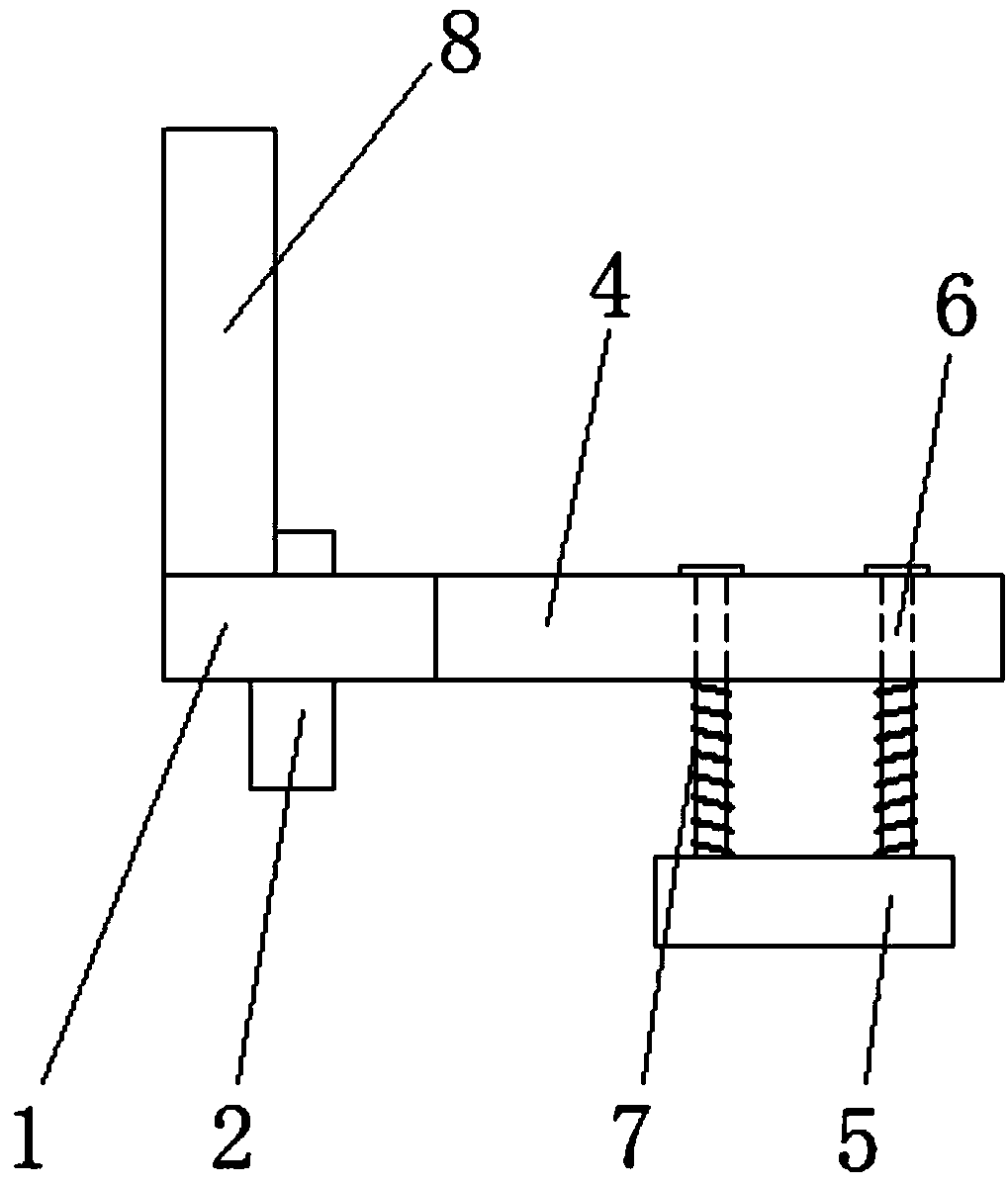

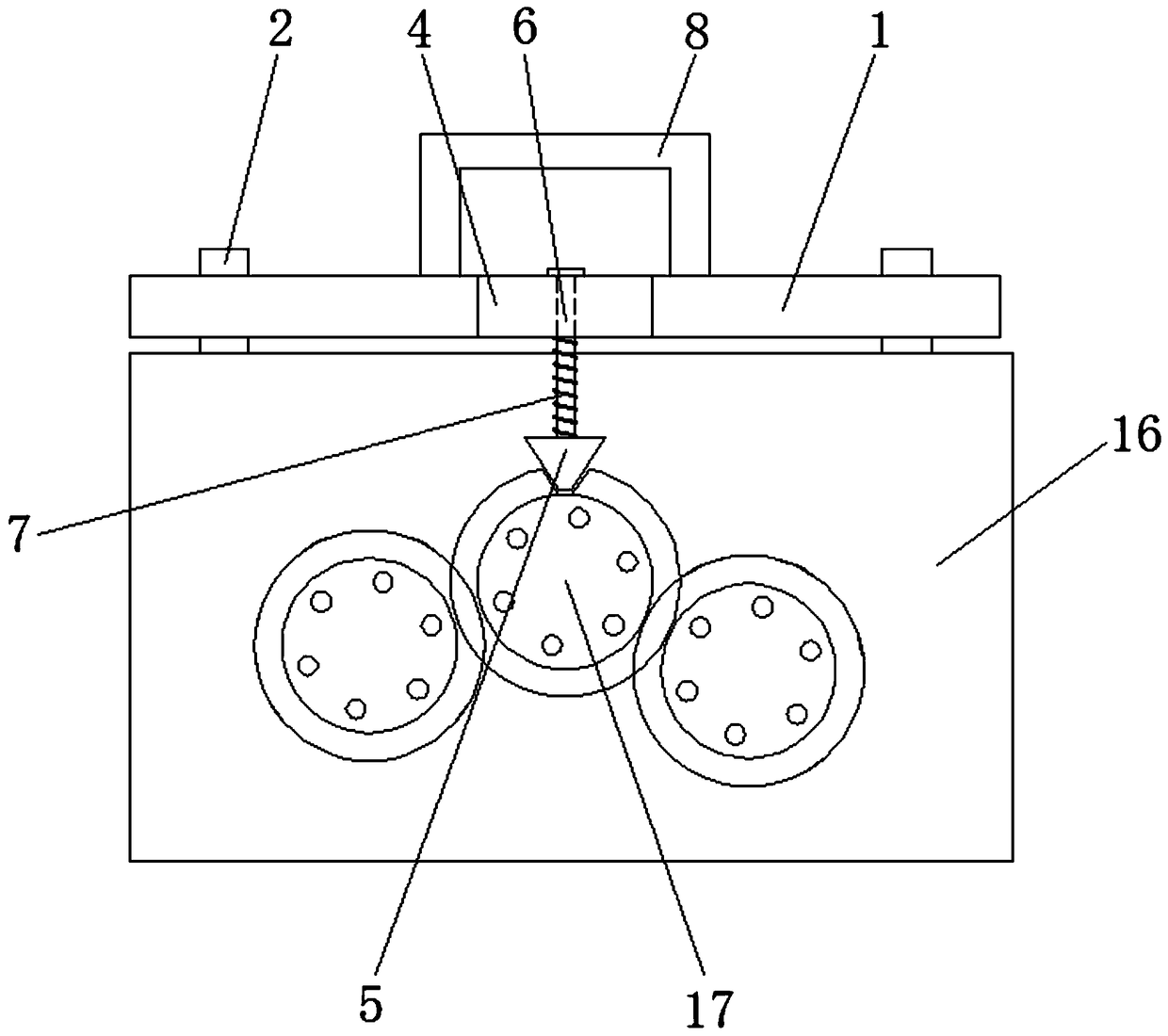

[0026] refer to Figure 4-5 , is a specific embodiment of the present invention. In this embodiment, its clamping assembly is slidably installed on the fixed plate 1 through a sliding assembly. The sliding assembly includes a guide rail 9 arranged on the fixed plate 1 and a connecting block 4 The slider 10 is slidingly connected with the guide rail 9, and the clamping assembly is set to a slidable form, and the position of the clamping block 5 can be adjusted appropriately so that the clamping block 5 can be completely engaged with the timing gear 17, thereby To achieve the purpose of protecting the gears from damage, since the snap-in assembly is movable, an adjustment assembly for adjusting the displacement of the snap-in assembly is also provided on the fixed plate 1. The adjustment assembly includes a turntable 11, a screw rod 12, and a support seat 13 , the support base 13 is installed on the fixed plate 1, the screw 12 is installed on the support base 13 through the bear...

Embodiment 2

[0028] refer to Figure 6-7 , is another specific embodiment of the present invention, this embodiment is basically the same as Embodiment 1, the difference is that a side positioning plate 14 that is hingedly connected to it is also provided on one side of the fixing plate 1, and the side positioning plate 14 can be Rotate relative to the fixed plate 1, a detachable auxiliary pin 15 is provided at one end of the side positioning plate 14, and the side positioning plate 14 is arranged on the same side as the clamping assembly, the auxiliary pin 15 is used to match with the front hole of the body 16, when fixed When the positioning pin 2 on the board 1 cannot complete the positioning, the clamping assembly can be positioned by using the auxiliary pin 15 to cooperate with the positioning pin 2, which expands the scope of application of the auxiliary device.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap