Reclaimed block precast concrete pier foundation and construction method thereof

A technology for concrete and prefabricated piers, applied in the field of concrete, can solve the problems of excavating a large amount of earthwork, large transportation volume, and high foundation cost, and achieve the effects of low recycling cost, low energy consumption for crushing, and quality assurance in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

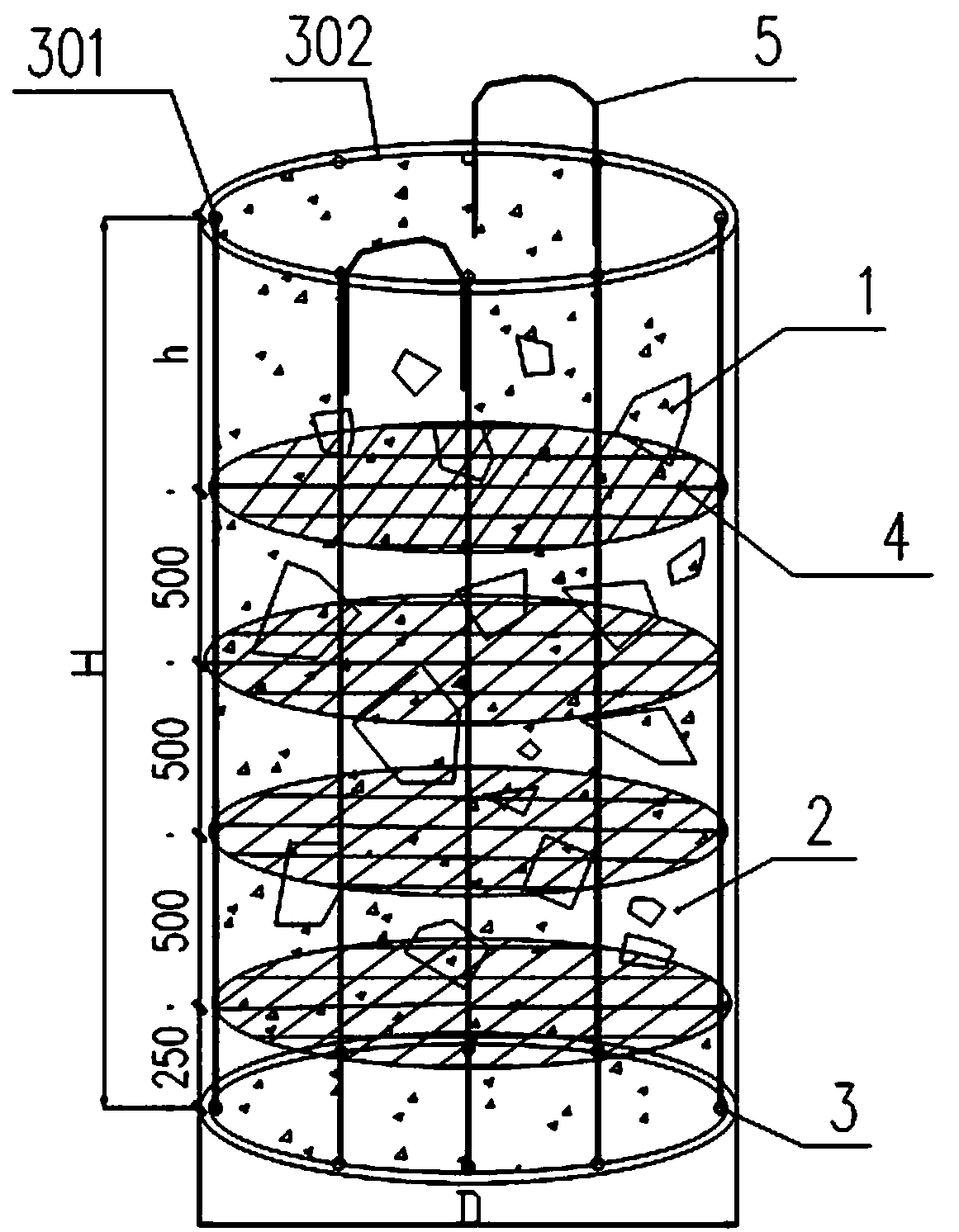

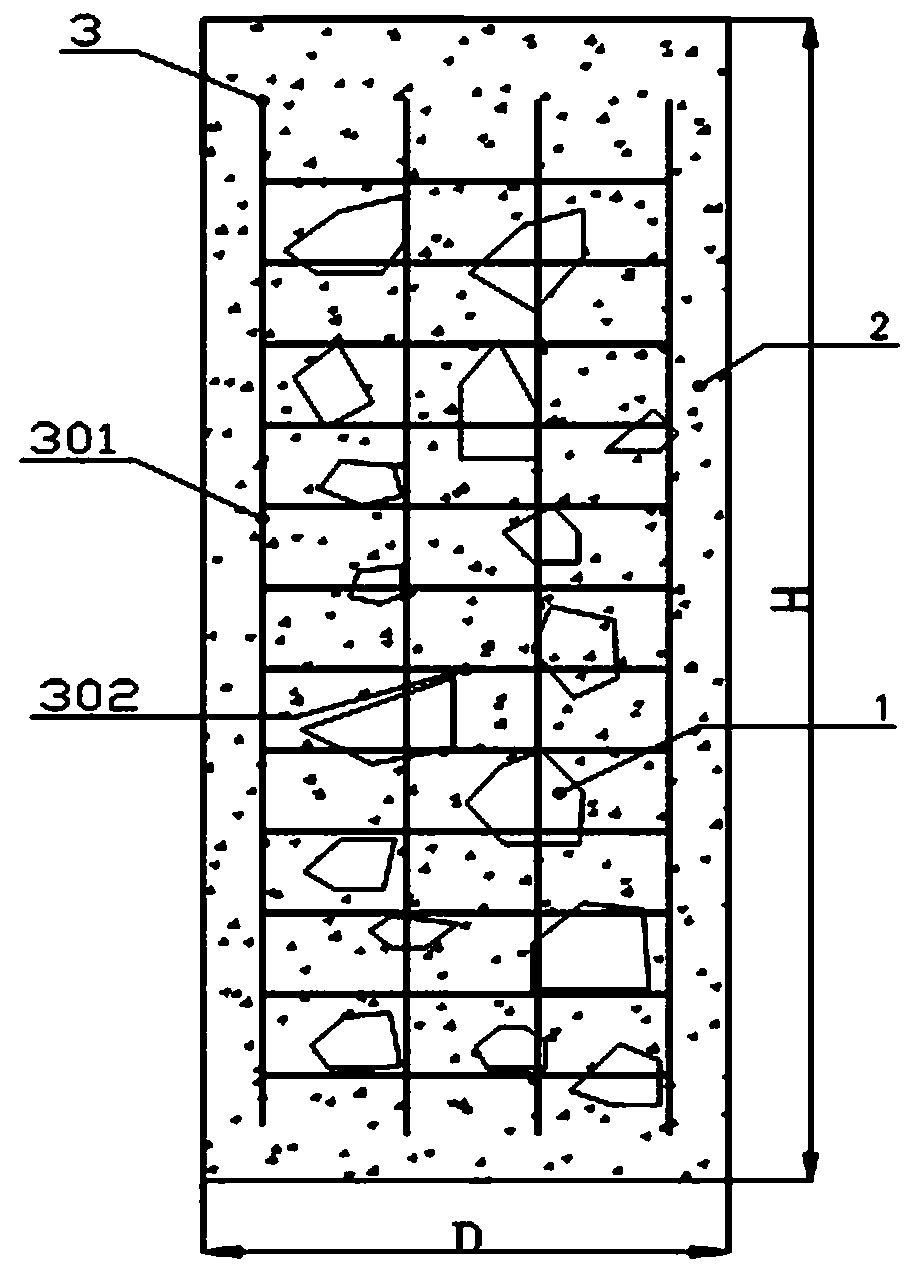

[0052] Example 1: A prefabricated pier foundation of recycled block concrete without reserved longitudinal reinforcement

[0053] (1) Customize the prefabricated pier foundation mold of recycled block concrete, and assemble and splice the mold.

[0054] (2) Set up scaffolding. On the one hand, it is used to fix the mold, and on the other hand, it is also used as an operation platform in the process of pouring concrete;

[0055] (3) According to the reinforcement cage (3) reinforcement requirements, the longitudinal reinforcement 301 is not less than 8Φ12mm, and the reinforcement ratio is not less than 0.15%, and the stirrup is 302Φ8@250mm, and is bound. The length of the longitudinal reinforcement 301 is 100mm shorter than that of the pier body. And select four longitudinal bars 301 symmetrically on the top of the reinforcement cage, and weld the lifting ring 5 on the corresponding longitudinal bars according to the corresponding design requirements (refer to figure 1 , f...

Embodiment 2

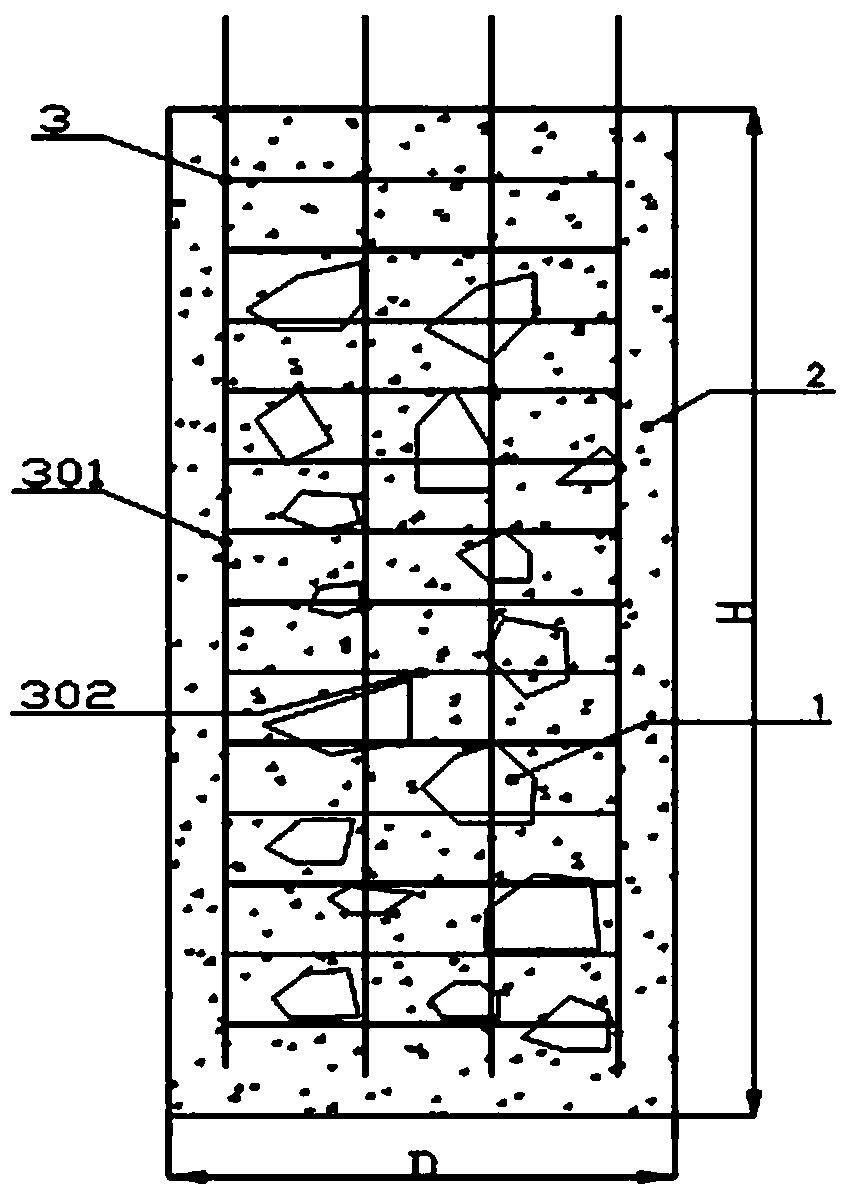

[0062] Example 2: A prefabricated pier foundation of regenerated block concrete with reserved longitudinal reinforcement

[0063] (1) Customize the prefabricated pier foundation mold of recycled block concrete, and assemble and splice the mold.

[0064] (2) Set up scaffolding. Set up scaffolding. On the one hand, it is used to fix the mold, and on the other hand, it is also used as an operation platform in the process of pouring concrete;

[0065] (3) According to the reinforcement requirement of the reinforcement cage 3, the longitudinal reinforcement 301 is not less than 8Φ12mm, and the reinforcement ratio is not less than 0.15%, and the stirrup (302)Φ8@250mm is bound. A part of the longitudinal reinforcement 301 is reserved outside the pier body, which is convenient for the extension of the prefabricated pier foundation of regenerated block concrete on site later. And select four longitudinal bars 301 symmetrically on the top of the reinforcement cage, and weld the lifti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com