Rotary contact assembly and rotary switch

A technology of rotating contacts and components, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of low assembly efficiency, low processing efficiency, and large volume, and achieve the goal of eliminating installation steps, improving processing efficiency, and simplifying processing procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

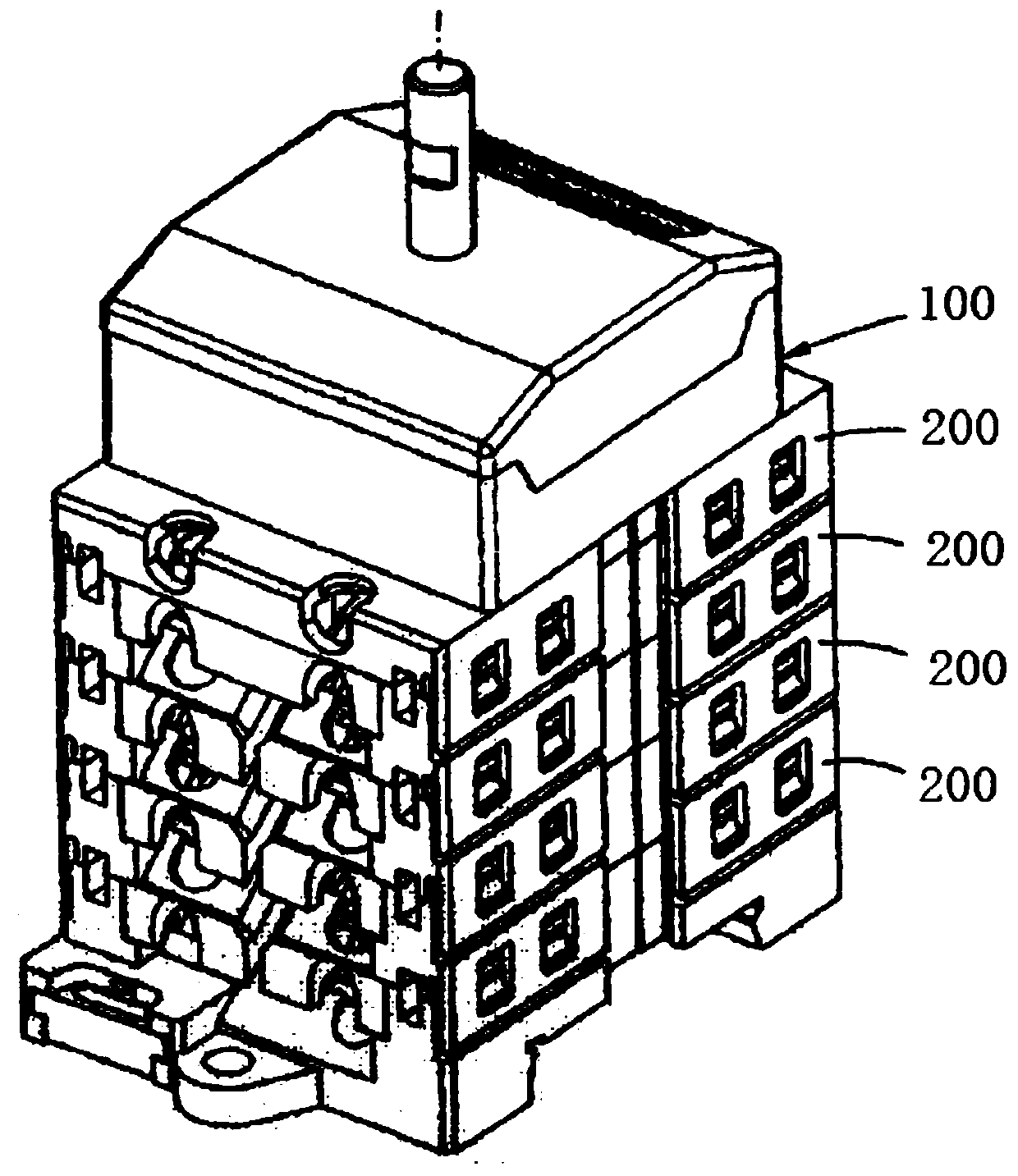

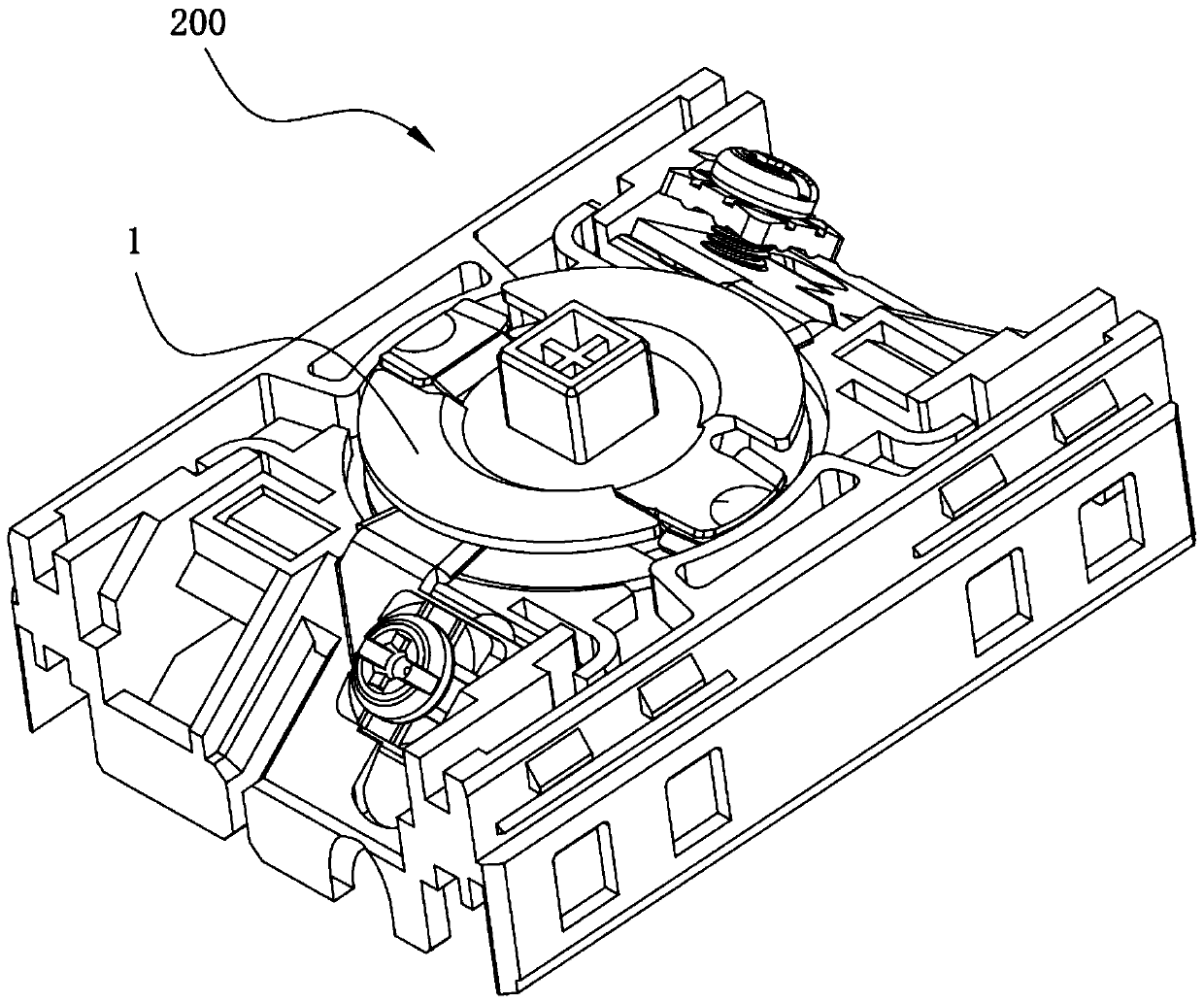

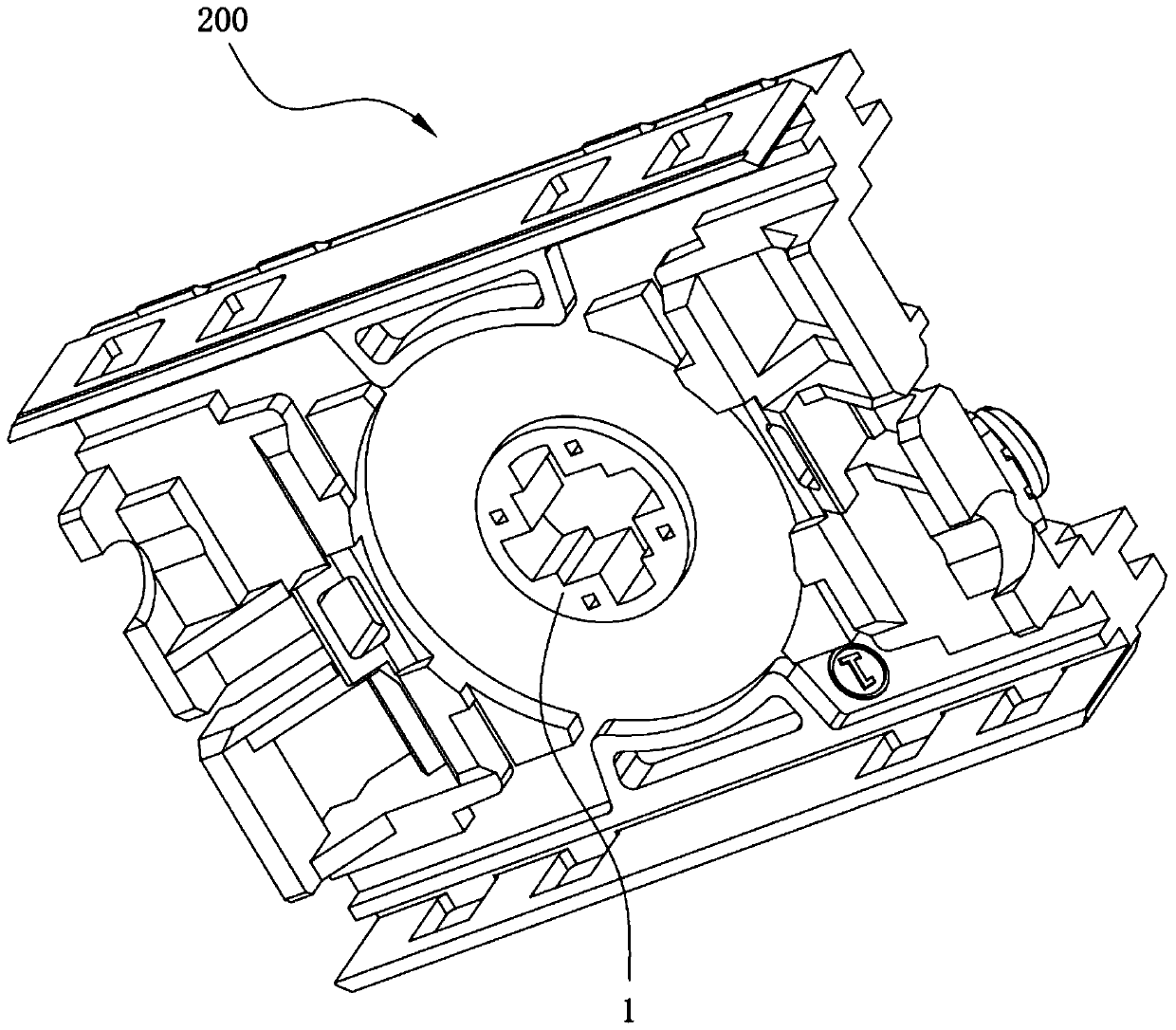

[0032] The embodiment discloses a rotary contact assembly and a rotary switch including the rotary contact assembly. Specifically, the rotary switch includes multiple sets of switch modules listed in sequence, such as figure 2 and image 3 As shown, a rotary contact assembly 1 is installed on each group of switch modules 200, wherein, figure 2 Shown is the front structure of the switch module, image 3 Shown is the rear structure of the switch module.

[0033] Such as Figure 4 to Figure 6 As shown, the rotary contact assembly includes an integrally formed insulating mandrel part, and a conductive part 11 is fixedly connected to the insulating mandrel part; wherein, the insulating mandrel part includes a cylindrical mandrel 12 and extends outward along the outer wall of the mandrel 12 The shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com