Multi-color-resin denture dentition and base-support split numerical control processing and splicing forming method

A technology of resin dentures and molding methods, applied in dental prosthesis, dentistry, dentures, etc., can solve the problem of not being able to truly reflect the physiology of dentures and artificial dentition, personalized occlusal surface CAD results, and not fully reflecting the convenience of digital processing, etc. Problems, to achieve the effect of simplifying work intensity, reducing production costs, and simplifying processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

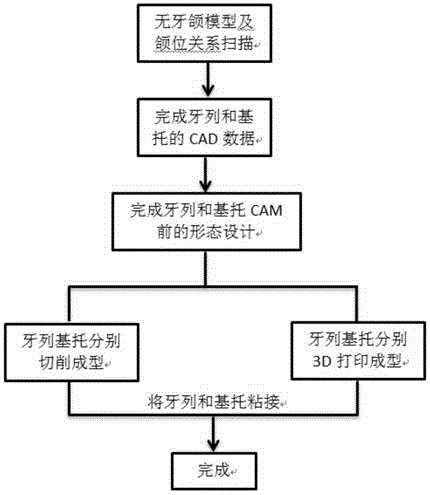

[0025] see figure 1 , a multi-color resin denture base split numerical control processing and bonding molding method of the present invention has the following steps:

[0026] 1) Obtain the patient's edentulous plaster model and (occlusal) tray;

[0027] 2) Scan the edentulous plaster model and the (occlusal) bracket obtained by scanning the 3D scanner for the dentition model, and register the scanned edentulous plaster model and the (occlusal) bracket to obtain a position with a median relationship. digital model, (occlusal) tray data;

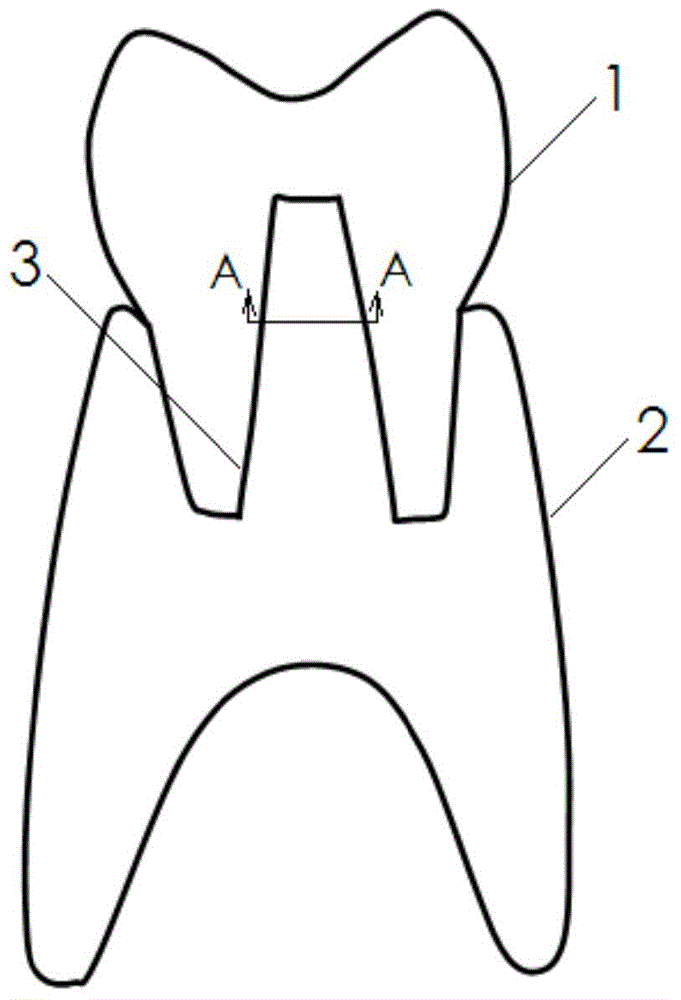

[0028] 3) Import the data into the CAD-based complete denture design software. After creating the occlusal plane and dental floss, use the three-dimensional graphic database of complete denture artificial teeth based on parametric positioning to find the data of the upper and lower teeth of the appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com