Steel skeleton parapet structure

A parapet, steel skeleton technology, applied in the direction of walls, building components, building structures, etc., can solve the problems that the anti-strong typhoon and seismic performance of the infill wall cannot meet the requirements, the shape of the concrete parapet is single, and the structural safety is affected. The structure is simple and beautiful, with significant economic benefits, and the effect of improving the resistance to strong typhoons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

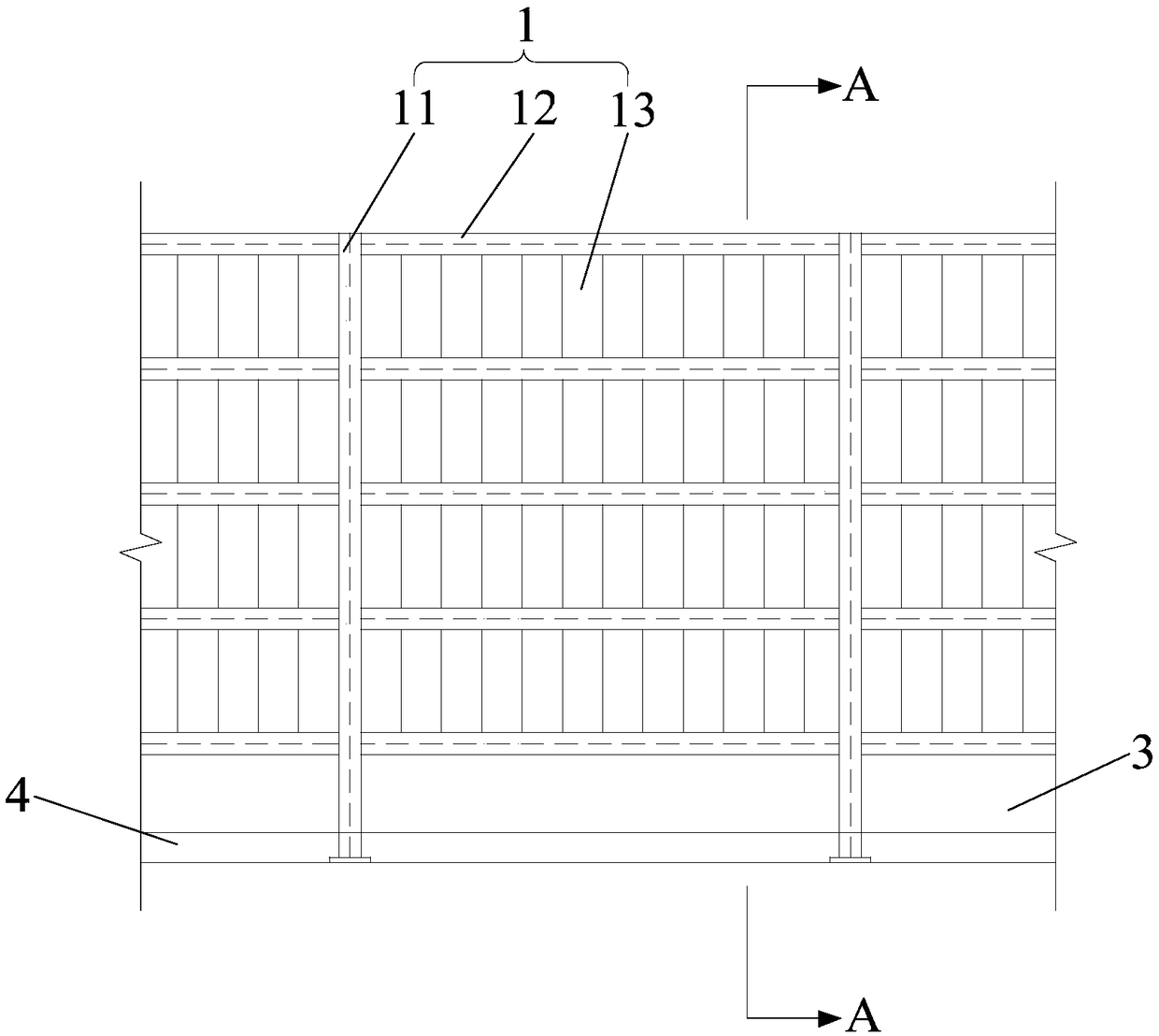

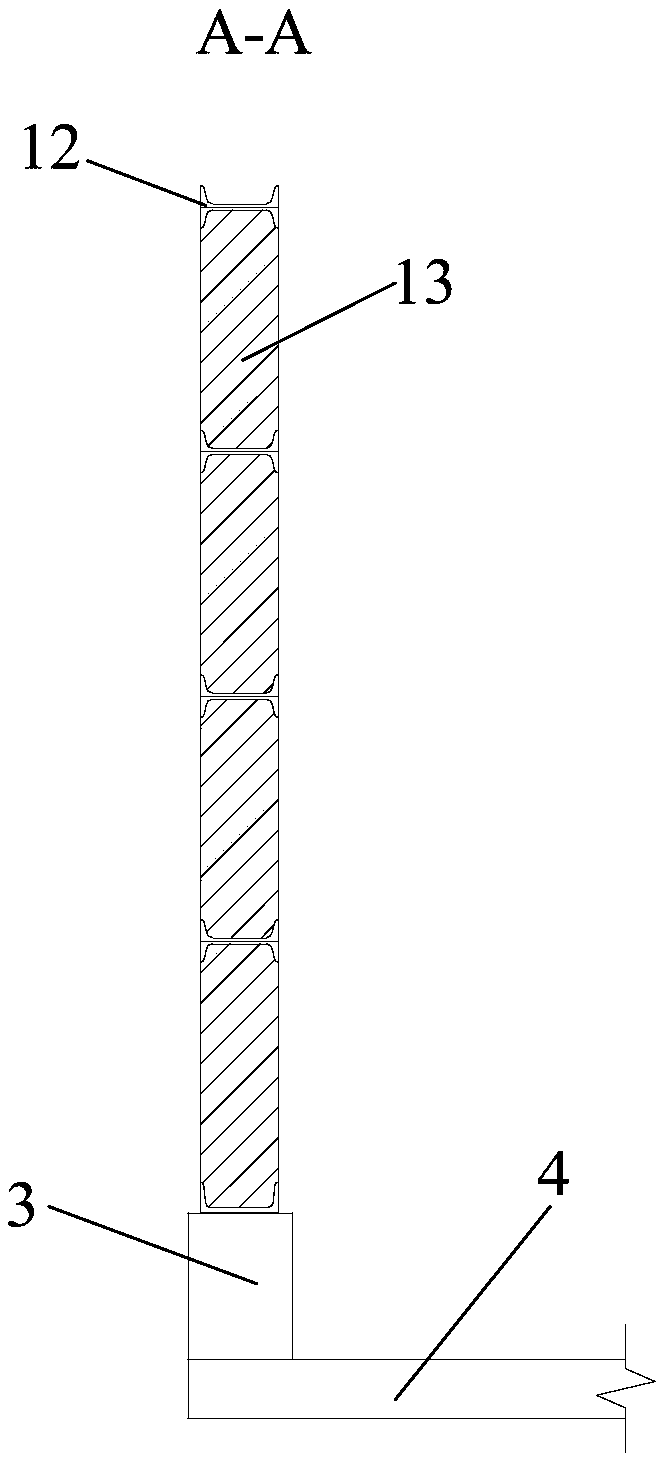

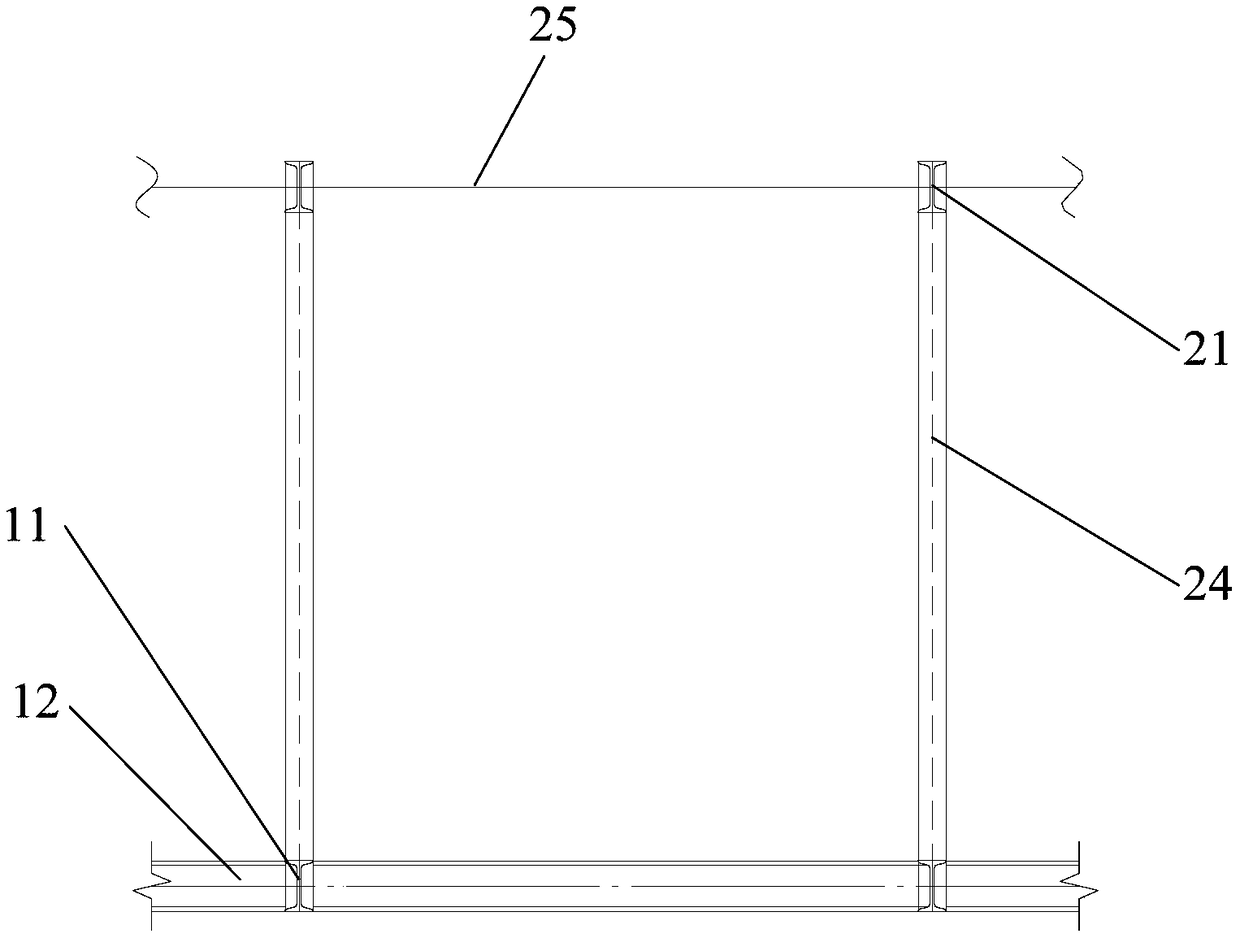

[0031] Such as figure 1 and Figure 5 As shown, the present invention provides a steel skeleton parapet structure, which includes at least one skeleton unit, and the skeleton unit includes a main body 1 and two support bodies 2, wherein the main body 1 includes two parallel and spaced apart main body steel columns 11, two Between the main steel columns 11, there are multiple horizontal steel beams 12 arranged at intervals from top to bottom, such as figure 1 , figure 2 and Figure 5 As shown, a plurality of building blocks 13 are filled between two adjacent cross steel beams 12 to form a closed wall layer, and the multi-layer wall layer on the main body 1 forms the main wall located on the facade of the building. The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com