Grader front wheel drive control valve and hydraulic system

A front-wheel drive and hydraulic system technology, which is applied to control devices, mechanical equipment, earth movers/shovels, etc., can solve the problems of short service life of motors and unilateral slipping of motors, and achieve extended service life and oil supply Timely, the effect of improving operation efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation will be described below in conjunction with the accompanying drawings.

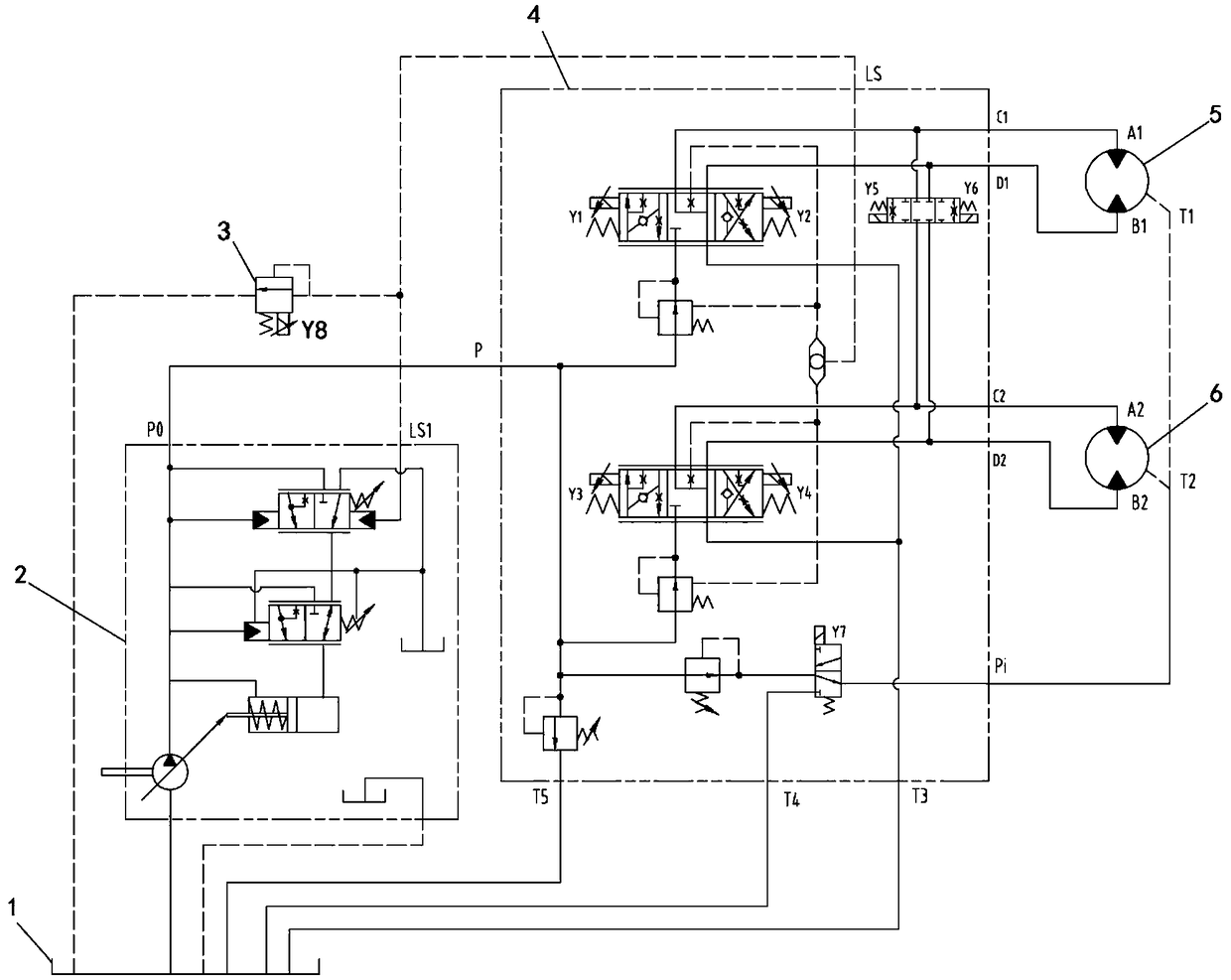

[0029] Such as figure 1 , Figure 4As shown, the hydraulic system for driving the front wheels of the grader in this embodiment includes a hydraulic oil tank 1, a drive pump 2, a working mode selection valve 3, a control valve for driving the front wheels of the grader 4, a left front wheel hydraulic motor 5, and a right front wheel Hydraulic motor 6, controller 7, rear wheel speed sensor 8, working mode input device 9, steering sensing device 10, engine speed sensor 11, working mode input device 12.

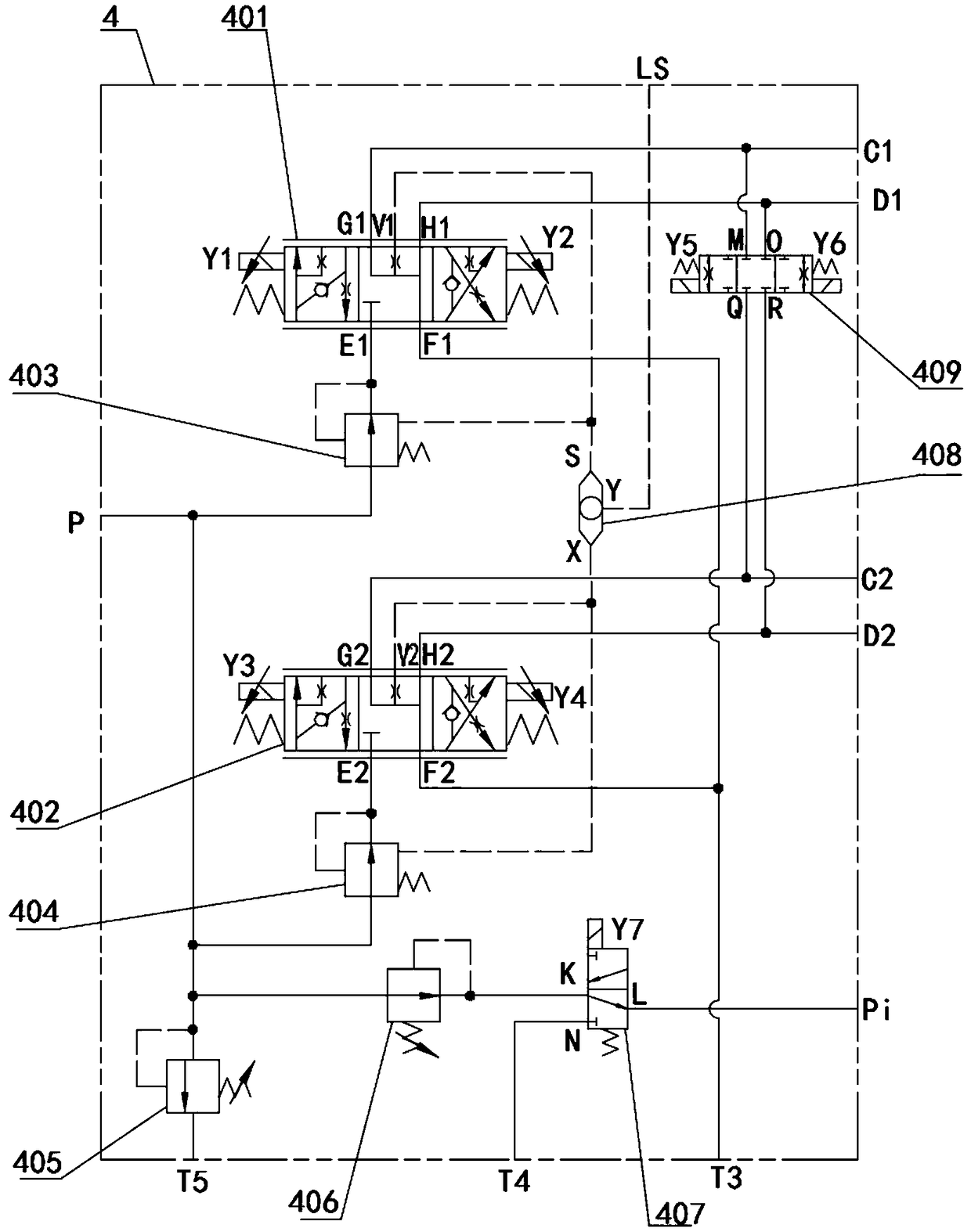

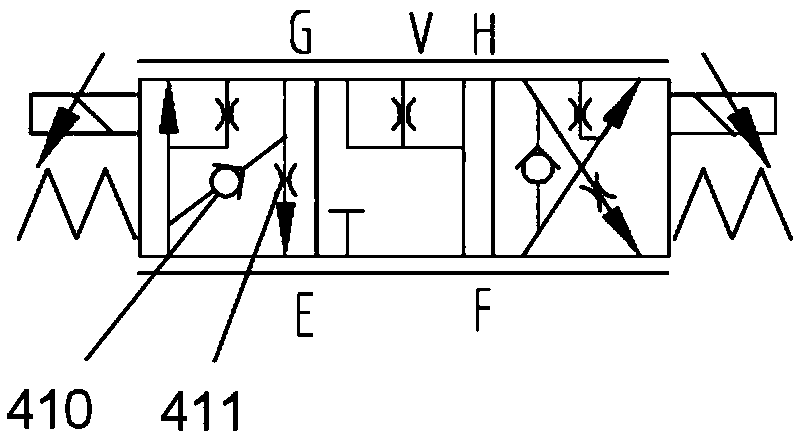

[0030] Such as figure 2 , image 3 As shown, the motor grader front wheel drive control valve 4 includes a left front wheel reversing valve 401, a right front wheel reversing valve 402, a left compensation valve 403, a right compensation valve 404, a main safety valve 405, a pressure reducing valve 406, a mode switching solenoid valve 407, Shuttle valve 408, two-way d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com