Rubber hose and manufacturing method

A rubber tube and natural rubber technology, applied in the direction of hoses, pipes, flange connections, etc., can solve the problems of pipelines that cannot meet the requirements of seismic isolation, large deformation of pipelines, low reaction force, etc., and achieve repeated deformation fatigue Excellent, strong deformation ability, low reaction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

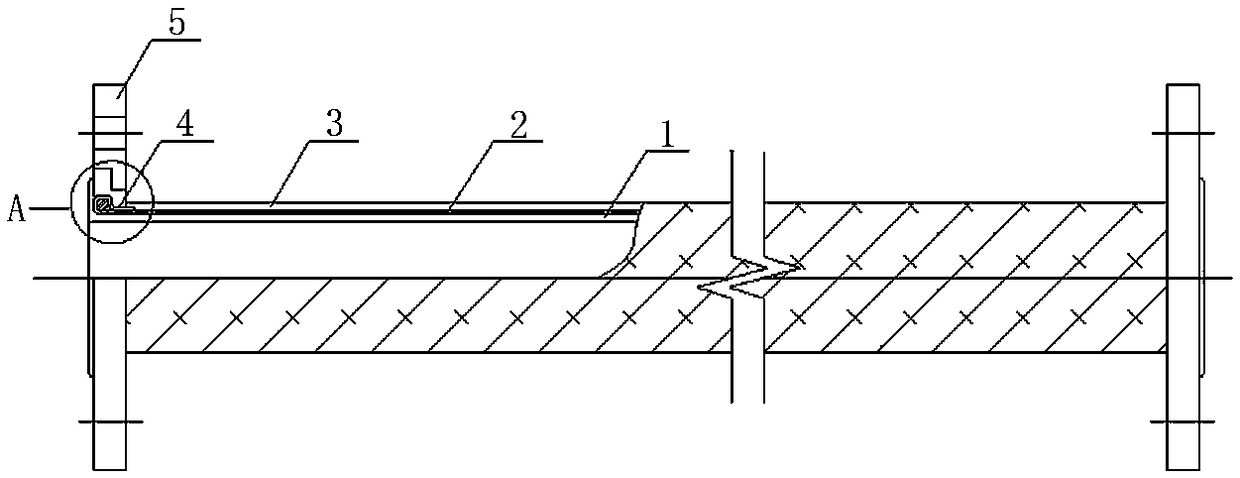

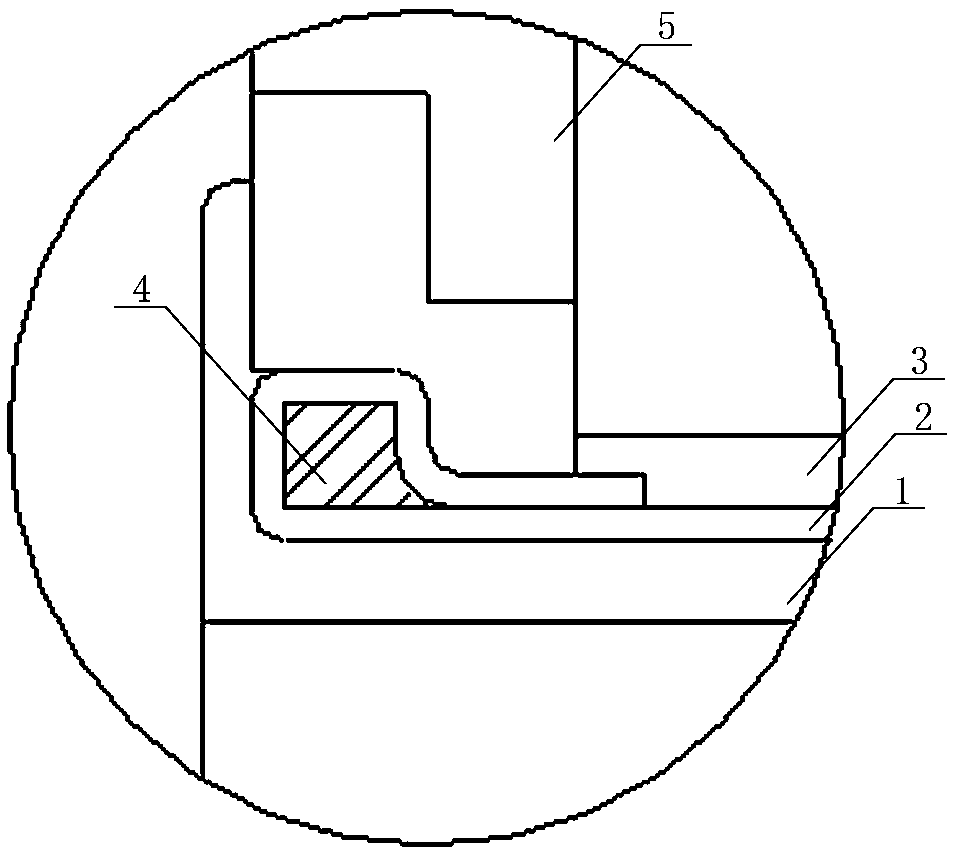

[0031] Examples see figure 1 As shown, this kind of rubber tube includes a hose segment and flanges 5 arranged at both ends of the hose segment. The tube wall of the hose segment includes an inner rubber layer 1, a reinforcing layer 2 and an outer Adhesive layer 3 ; the end of the reinforcement layer 2 is wound around the limiting ring 4 and embedded in the tongue and groove of the flange 5 . The flange shown is a movable movable flange, the inner ring is stepped, and a tenon groove is formed on the step surface. The hole diameter and hole position are in accordance with the requirements of the flange national standard, and the material is Q235 steel.

[0032] see figure 2 As shown, the end of the inner rubber layer 1 passes through the flange and is horizontally folded outward to cover the outer end surface of the flange, and the length exceeds the tongue and groove position of the flange.

[0033] The end of the reinforcing layer 2 is folded outwards at 180 degrees, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com