Method and device for measuring three-dimensional shape of mirror surface object

A technology of three-dimensional shape and measurement method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that non-continuous objects cannot be measured, non-continuous objects cannot be measured, and measurement accuracy cannot be given, so as to reduce the Effects of noise, fast acquisition speed, and the effect of taking into account measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

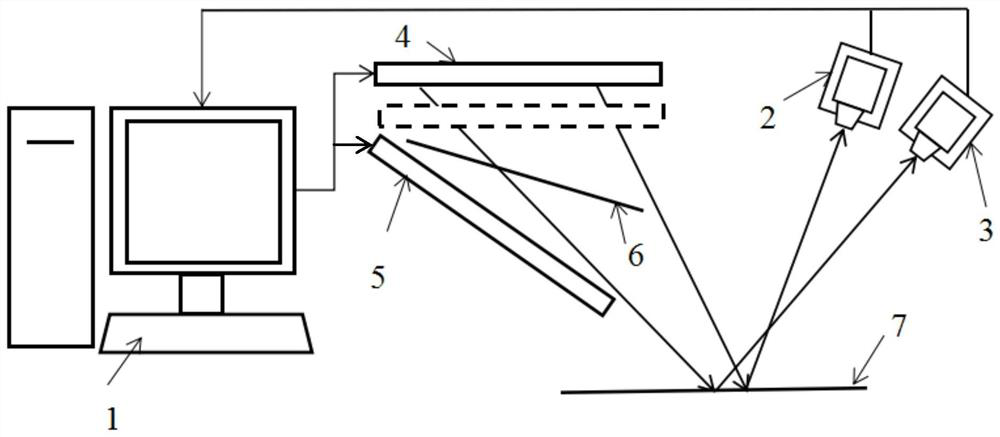

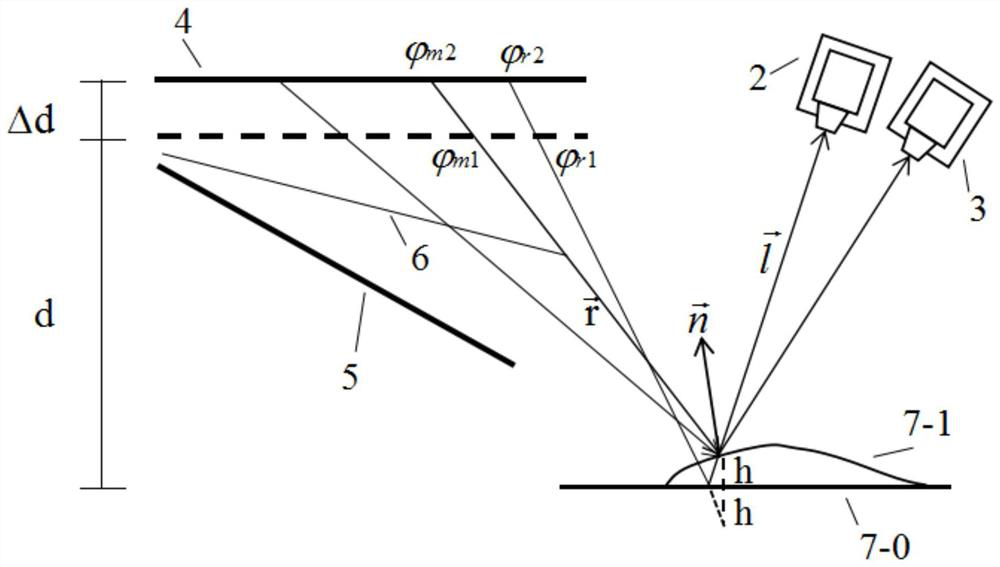

[0046] The invention provides a device for measuring the three-dimensional shape of a mirror object (referred to as the device, see figure 1 ), characterized in that the device includes a computer 1, a master camera 2, a slave camera 3, a refraction display screen 4, a reflective display screen 5, a half mirror 6 and a fixing device 7; the master camera 2, the slave camera 3, a refraction display Screen 4, reflection display screen 5, half mirror 6 and fixing device 7 are fixed on the optical platform; Refraction display screen 4, reflection display screen 5 and half mirror 6 are all perpendicular to the optical table; Fixing device 7 is in In the public field of view of the main camera 2 and the slave camera 3; the reflection display scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com