Blow drying machine for vehicle body with automatic profiling

It is an automatic and vehicle body technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of large hood drop, hood rear view glass, and water on the surface of the trunk that cannot be cleaned, so as to facilitate penetration leaky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

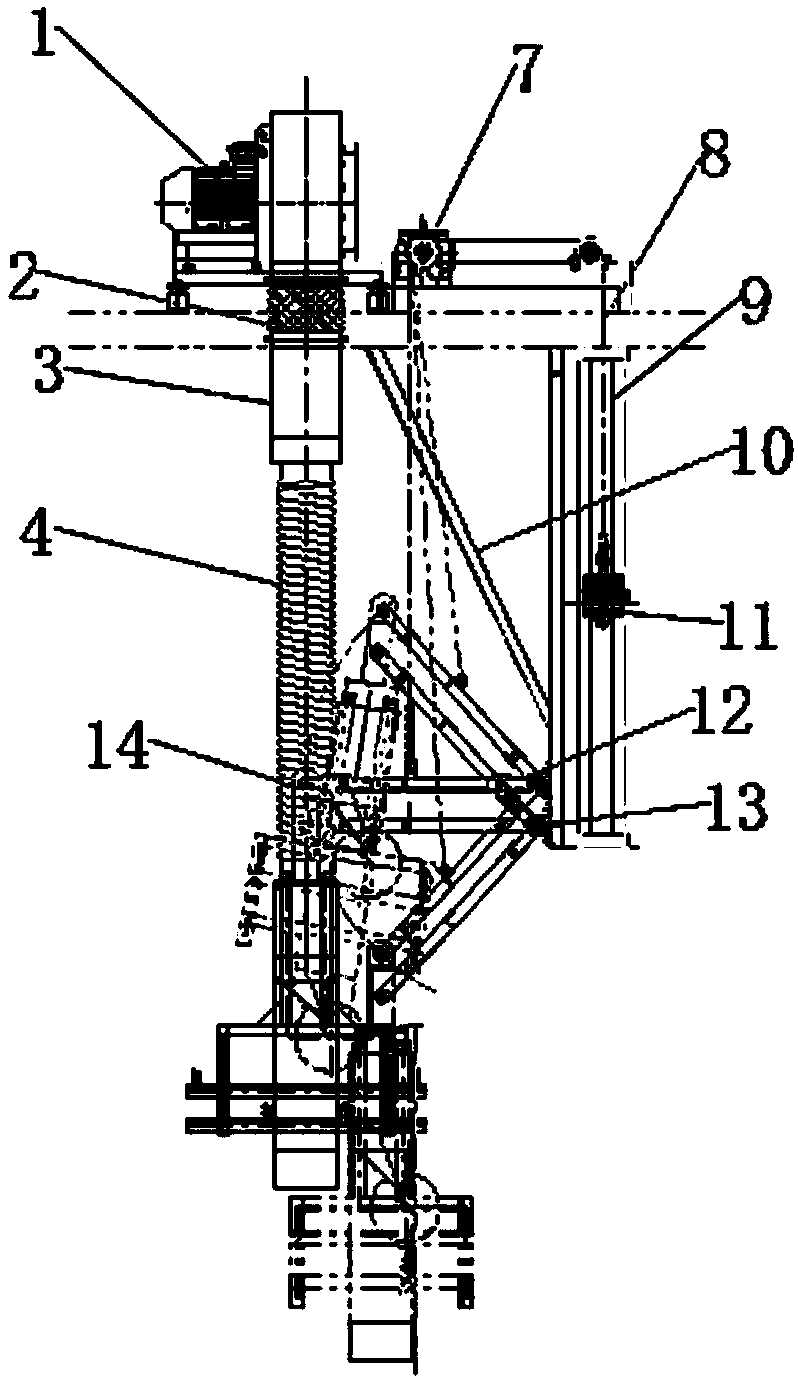

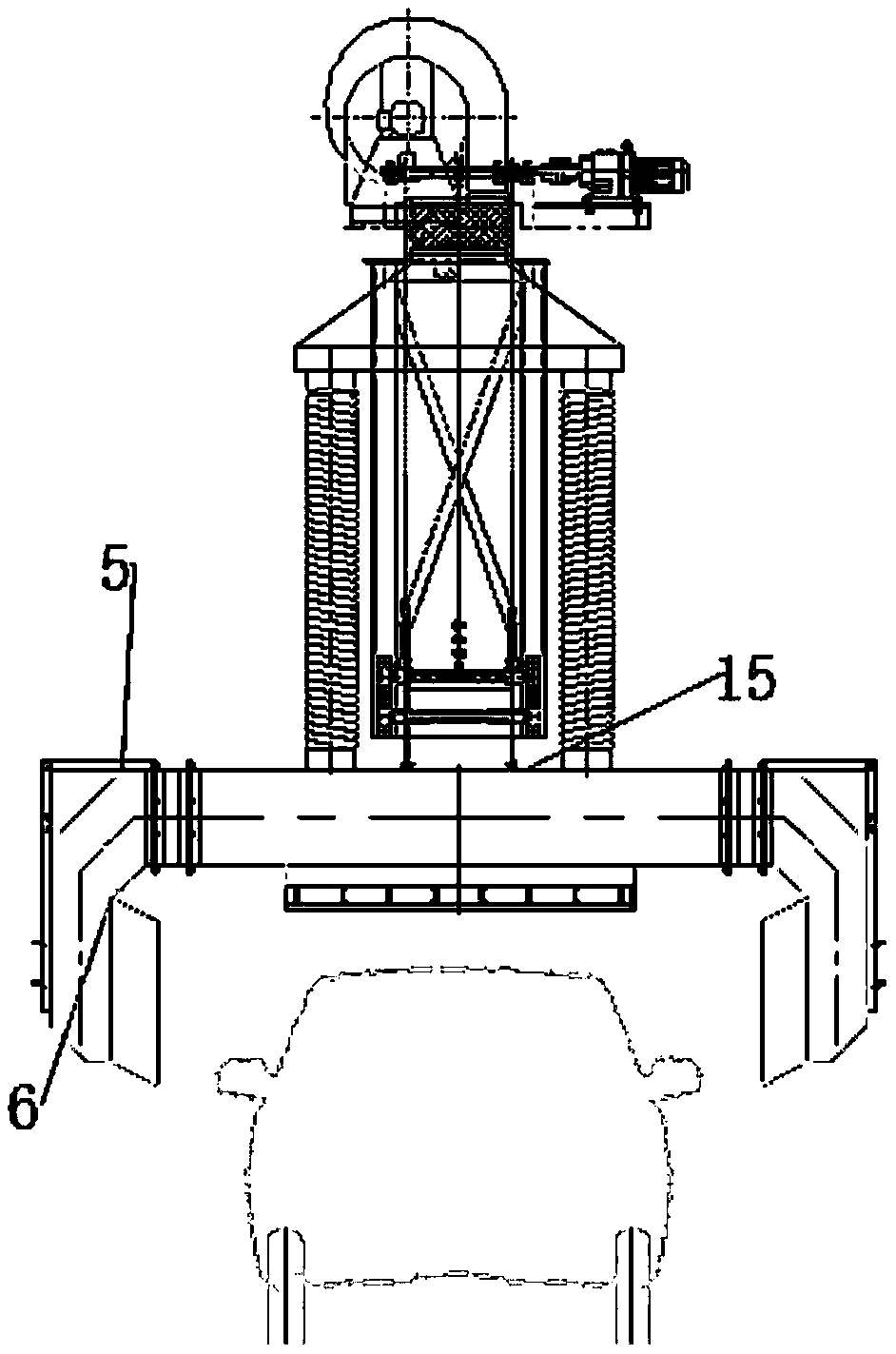

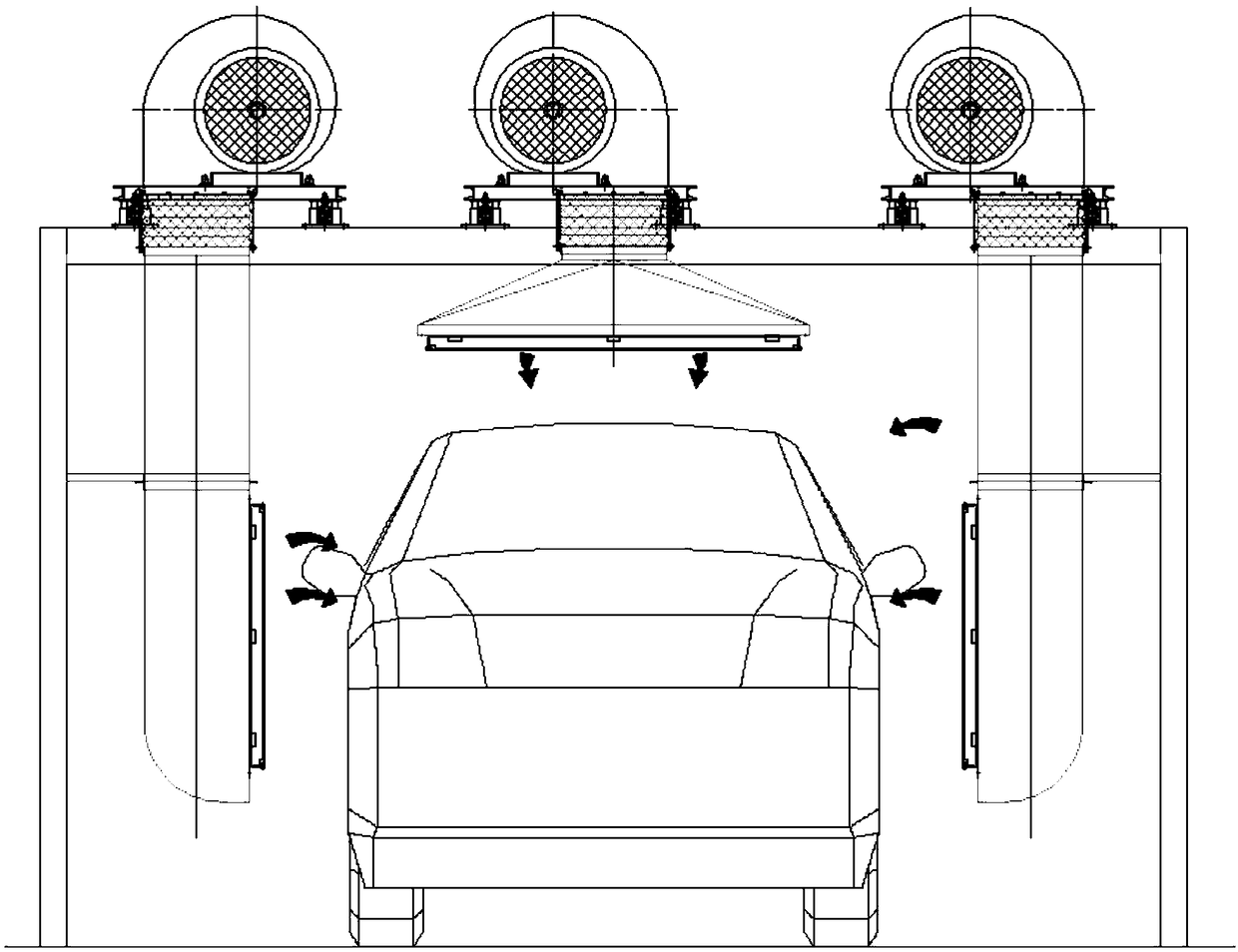

[0028] see Figure 1-6 , in an embodiment of the present invention, an automatic profiling drying equipment for a car body, including a support plate, a detection line plate chain, a centrifugal fan 1, an air supply pipe 3, a driving device 7, a roller chain 8 and a counterweight frame 9, the A centrifugal fan 1, a driving device 7, and a roller chain 8 are placed on the support plate, the lower end of the centrifugal fan 1 is provided with a soft connection assembly 2, and the lower right side of the soft connection assembly 2 is provided with a fixed connection The counterweight frame 9, the other end of the counterweight frame 9 is fixedly connected to the inner surface of the left side of the roller chain 8, the centrifugal fan 1 is connected to the air supply pipe 3 through the soft connection assembly 2, and the air supply pipe 3 is provided with a wire expansion tube 4, the lower end of the wire expansion tube 4 is provided with a connection plate 14, the front side of ...

Embodiment 2

[0031] It also includes a safety protection device. In order to prevent the blowing air pipe from contacting the body, a set of safety protection device is installed. There are two Φ4 waist-shaped holes in the center of the drying air pipe near the drying outlet, and the holes are equipped with A stainless steel ring, the surface of the ring is lined with plastic to reduce the buffer caused by the collision with the car body. Sensor switches are installed at both ends of the inner and outer rings of the water blowing duct. After the ring rises due to the collision with the car body, Break away from sensing the first detection switch and the second detection switch, and the blow-dry air duct immediately rises to the upper limit position.

[0032] An automobile rain test device includes the automatic profiling and drying equipment for a vehicle body.

[0033] The working principle of the present invention is:

[0034]The car is parked on the detection line plate chain, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com