Heating container capable of detecting and preventing leakage of high-temperature metallic material and manufacturing method thereof

A technology for heating containers and metal materials, applied in metal material coating technology, metal processing equipment, semiconductor/solid-state device manufacturing, etc., can solve problems such as material loss, achieve quality assurance, overcome abnormal material loss, and overcome production schedule interruptions problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

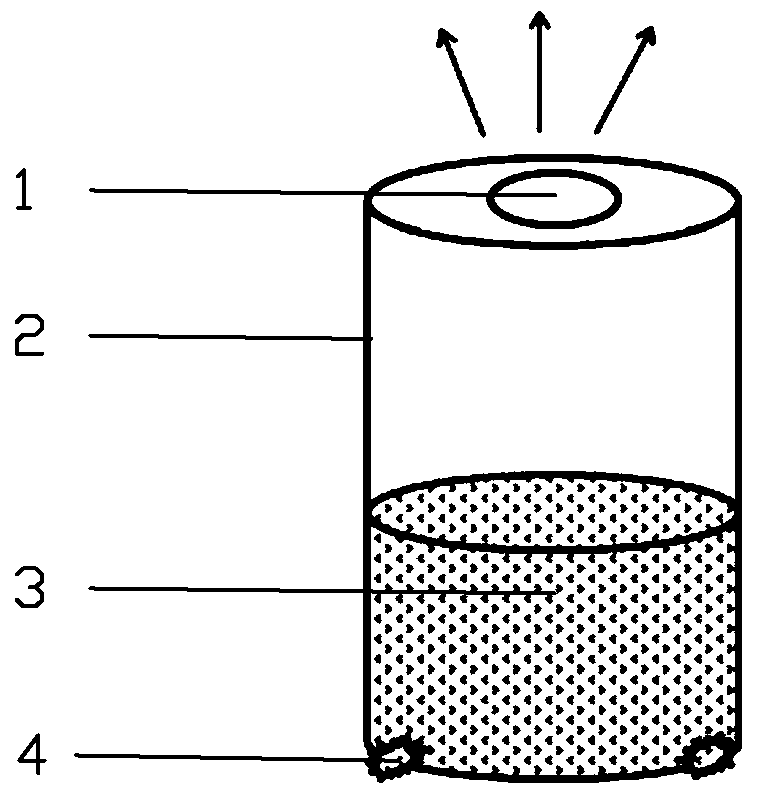

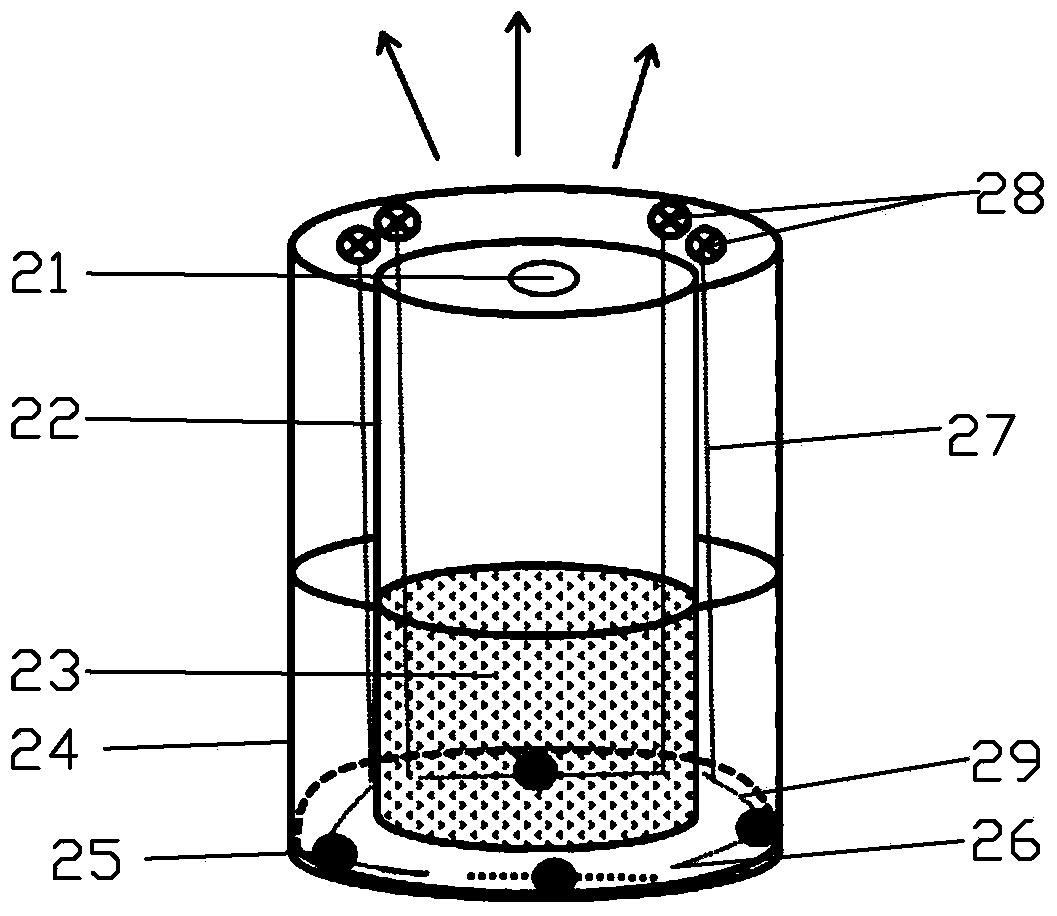

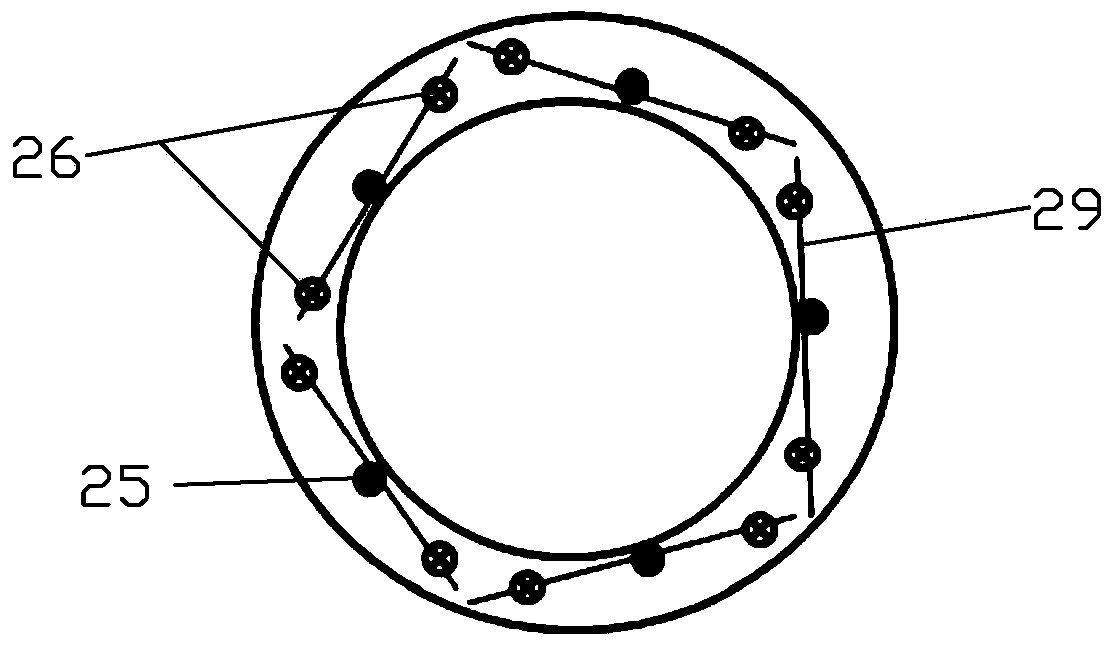

[0030] see figure 2 , which is a structural schematic diagram of a preferred embodiment of a heating vessel capable of detecting and preventing leakage of high-temperature metal materials in the present invention. The heating container capable of detecting and preventing the leakage of high-temperature metal materials mainly includes: an internal heating container 22 for containing the metal material 23, an external heating container 24 for containing the internal heating container 22 and being heated by a heating device, and a detection device (not shown in the figure), in this preferred embodiment, the heating container is a heating container used for the OLED evaporation process, so an air hole 21 is provided above the internal heating container 22, and the metal material 23 contained in the internal heating container 22 After being heated and evaporated, it can escape from the air hole 21 in the direction of the arrow; between the internal heating container 22 and the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com