A device and method for restoring the surrounding rock-lining contact surface produced by tension splitting

A contact surface and contact surface model technology, which is applied to the device of the surrounding rock-lining contact surface, restores the field of the surrounding rock-lining contact surface caused by tension splitting, and can solve the problem that the shear test cannot be repeated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Restoring the surrounding rock-lining contact surface includes the following steps:

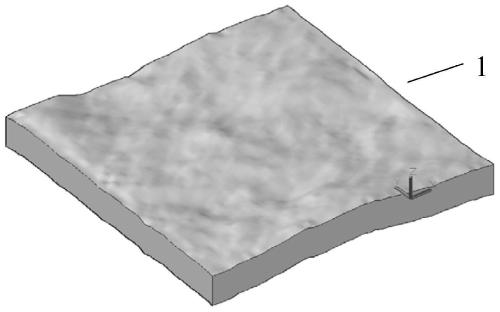

[0040]According to the principle of drilling and blasting construction, the rock mass at the face of the tunnel is split and destroyed due to the impact tensile stress to form the surrounding rock-lining contact surface, using the Brazilian disc test method, the cylindrical rock with a diameter of 150 mm and a thickness of 150 mm was tested. The sample was split, and a higher loading rate was used in the split to simulate the blasting impact; after the test, a split contact surface with a projected area of 150×150mm was obtained, and a high-precision three-dimensional scanning device was used to conduct a split contact surface Scan to obtain the point cloud data of the split contact surface in the form of three-dimensional coordinates and import it into MATLAB software for interpolation and fitting, generate a CAD script file, load the CAD script file into the CAD, form a three-dimens...

Embodiment 2

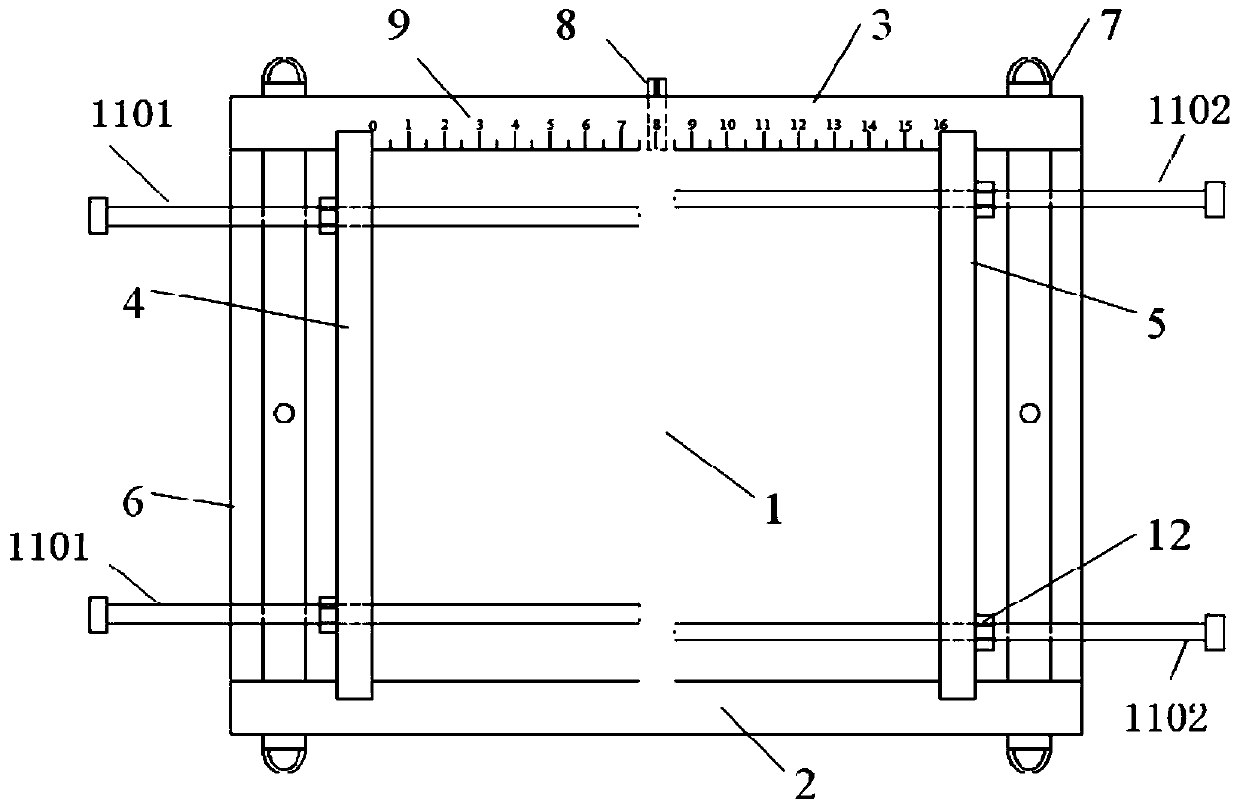

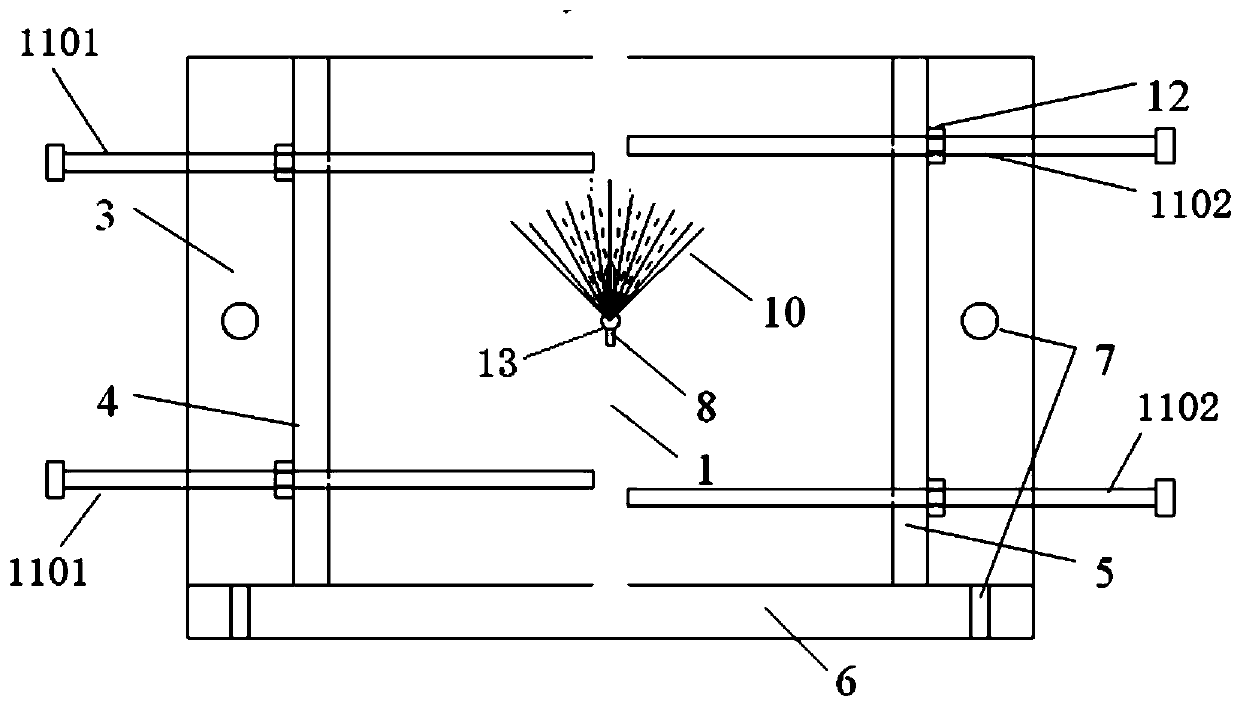

[0048] Using a device for restoring the surrounding rock-lining contact surface produced by tension splitting as described in Example 1, the method of restoring the surrounding rock-lining contact surface produced by tension splitting was carried out to prepare a test specimen with a size of 150×150×150mm. Like this, the thickness of the surrounding rock-lining contact surface model 1 is 10mm, so the distance between the inside of the left side plate 4 and the inside of the right side plate 5 is 160mm, and the distance between the inside of the front panel 2 and the inside of the rear panel 3 is 150mm. The heights of the left panel 4, the right panel 5, the front panel 2 and the rear panel 3 are all 150 mm, and the left panel 4, the right panel 5, the front panel 2 and the rear panel 3 are fixed on the bottom panel 6 with screws, and the left The side panel 4, the right side panel 5, the front panel 2 and the rear panel 3 form a square frame mold, place the surrounding rock-lin...

Embodiment 3

[0050] Using a device for restoring the surrounding rock-lining contact surface produced by tension splitting as described in Example 1, the method of restoring the surrounding rock-lining contact surface produced by tension splitting was carried out to prepare a test specimen with a size of 150×150×150mm. Like this, the thickness of the surrounding rock-lining contact surface model 1 is 10mm, so the distance between the inside of the left side plate 4 and the inside of the right side plate 5 is 160mm, and the distance between the inside of the front panel 2 and the inside of the rear panel 3 is 150mm. The heights of the left panel 4, the right panel 5, the front panel 2 and the rear panel 3 are all 150 mm, and the left panel 4, the right panel 5, the front panel 2 and the rear panel 3 are fixed on the bottom panel 6 with screws, and the left The side panel 4, the right panel 5, the front panel 2 and the rear panel 3 form a square frame mold, place the surrounding rock-lining c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com